Electrostatic dust collector for air purification

An electrostatic dust collection and air purification technology, applied in electrode conveying devices, electrostatic separation, electrostatic effect separation, etc., can solve the problems of small dust collection area, high manufacturing cost, inconvenient cleaning, etc., and achieve large dust collection area and manufacturing cost. Low, easy-to-clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

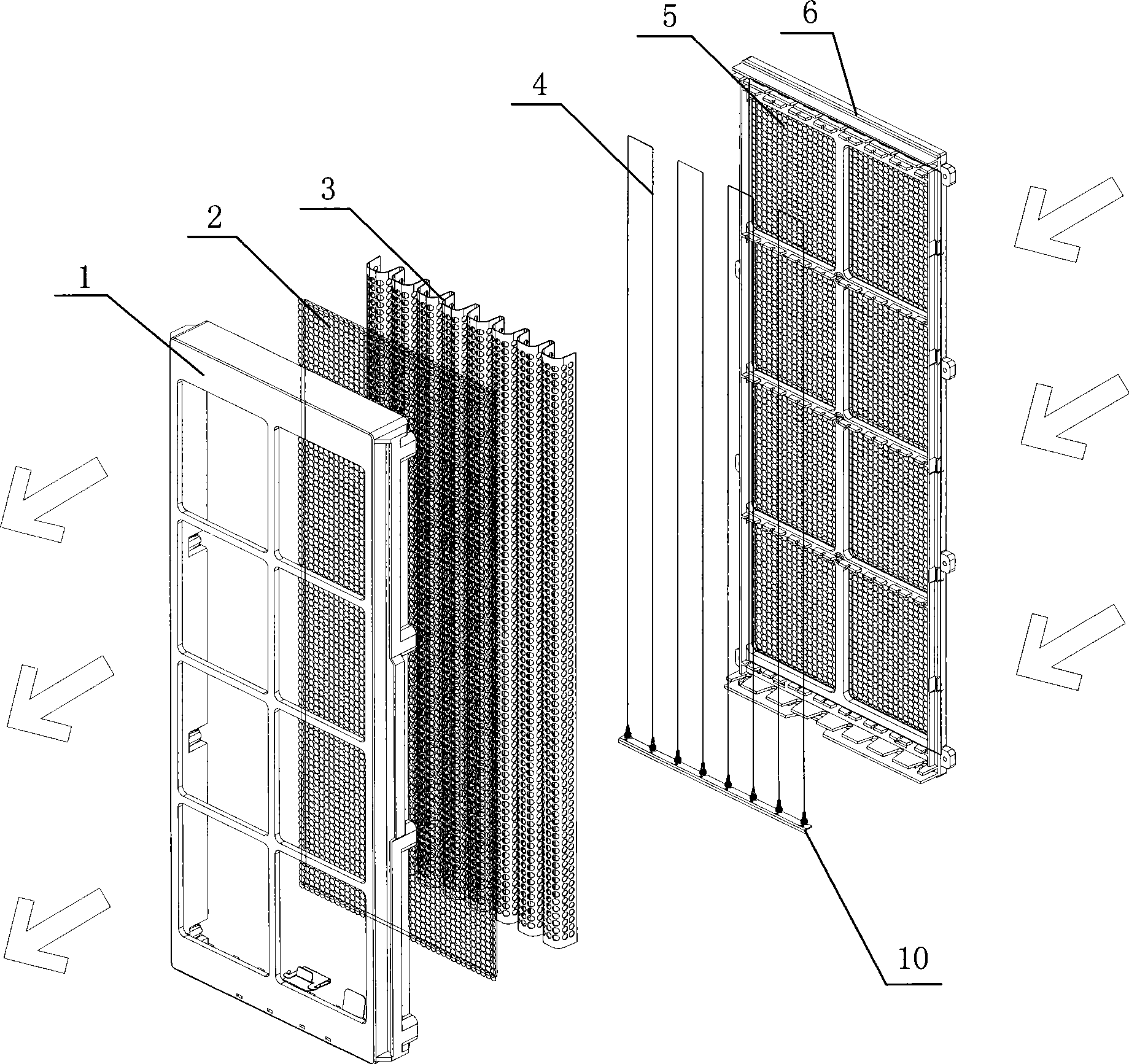

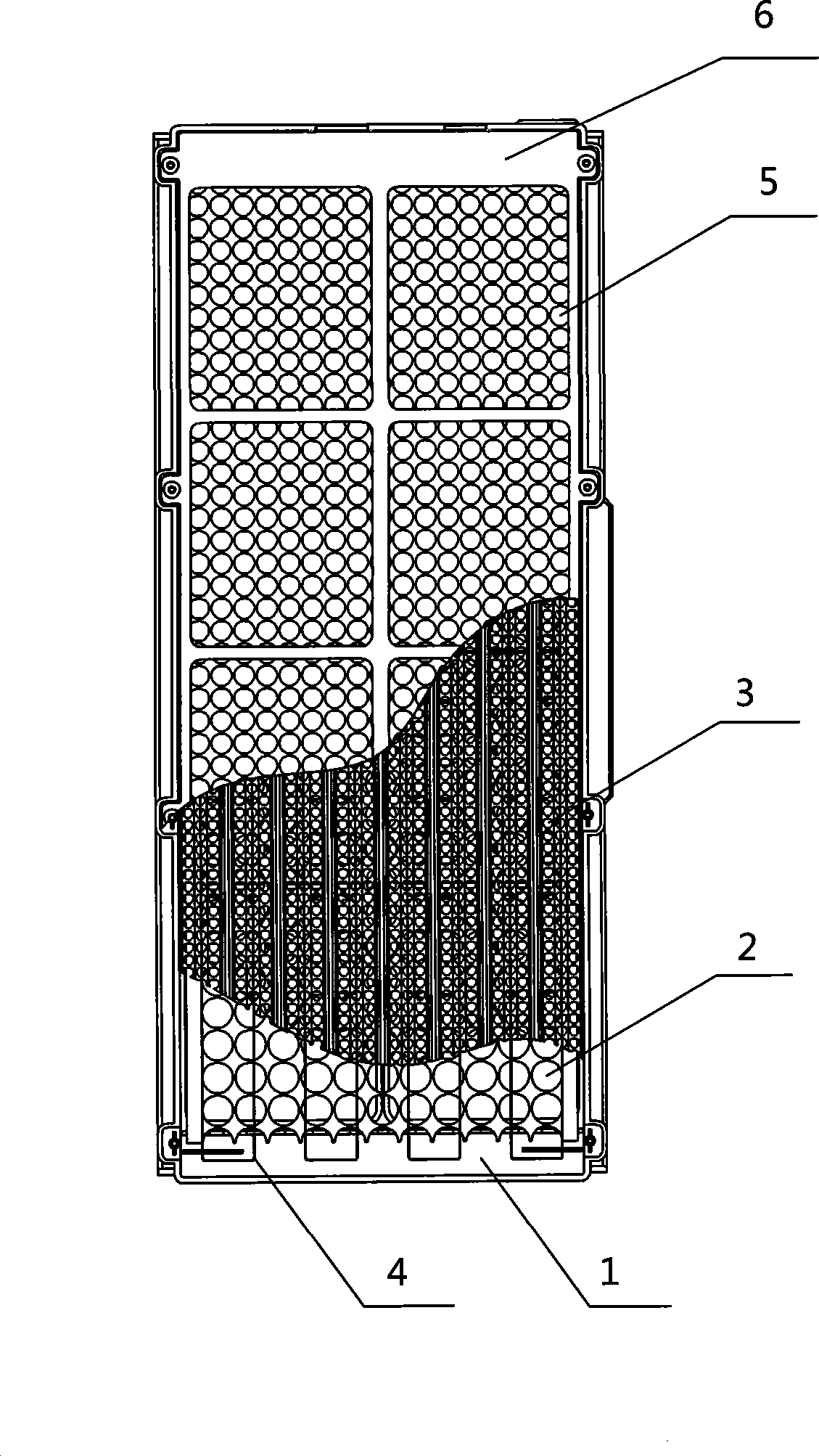

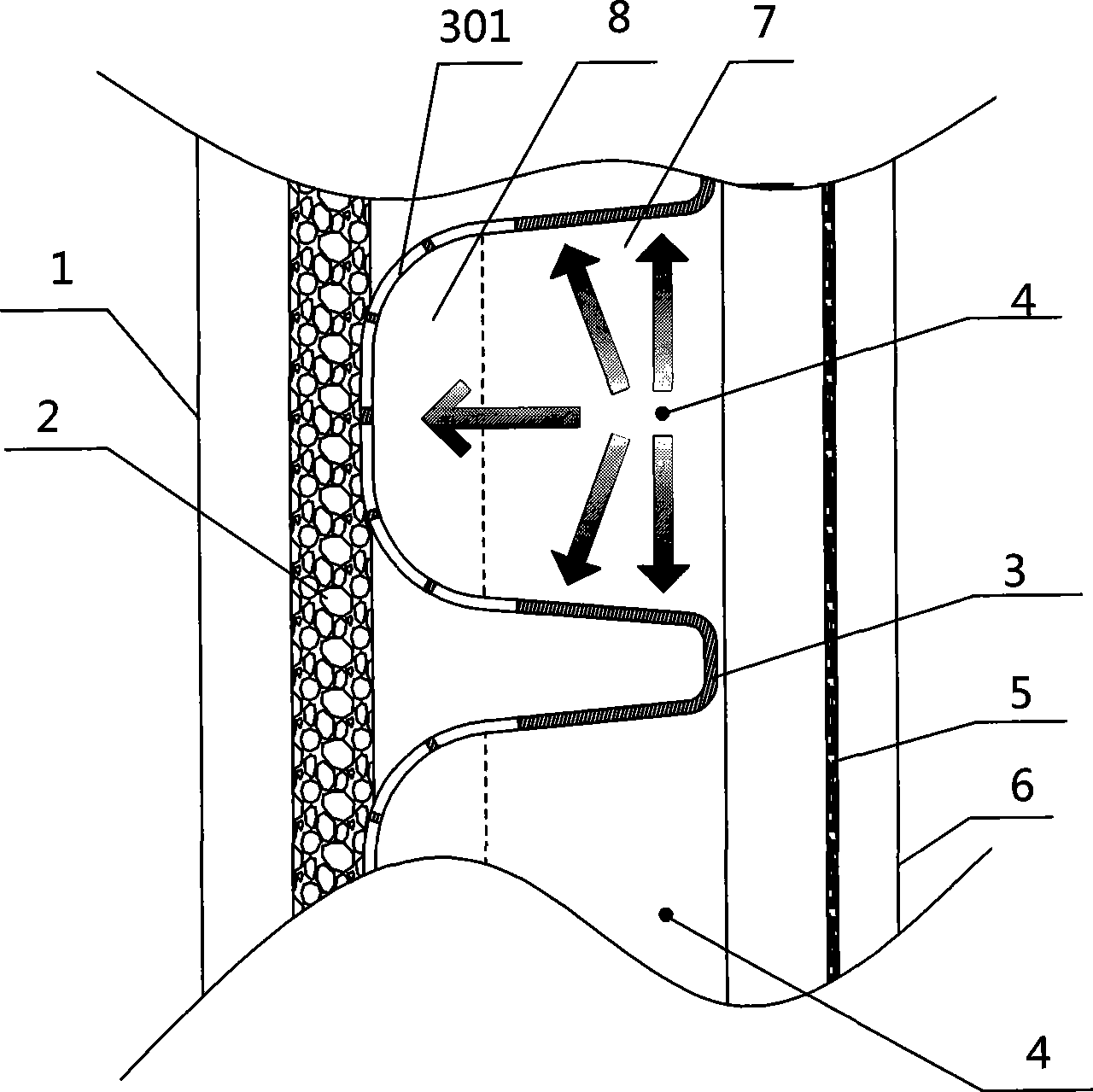

[0010] see figure 1 , figure 2 and image 3 , the present embodiment includes an insulating shell and an electrostatic field assembly fixed in the insulating shell. The insulating shell is composed of an insulating frame 1 provided with an air outlet and a primary filter frame 6 provided with an air inlet. The electrostatic field assembly includes a hole-type dust collection Pole plate 3 and a group of parallel corona wires 4. The hole-shaped dust-collecting pole plate 3 in this embodiment adopts a corrugated plate, which is bent from a stainless steel hole-shaped plate. The hole-shaped dust-collecting pole plate 3 The holes 301 are ventilation holes, and a group of parallel U-shaped grooves are arranged on the windward side of the hole-type dust collecting plate 3 corresponding to the corona wire 4, and one groove corresponds to a corona wire 4, and the corona wire 4 Parallel to the hole-shaped dust-collecting plate 3 and located in the groove of the hole-shaped dust-colle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com