Method for producing large-diameter high-speed resin cutting slice and heavy-load resin grinding wheel

A technology of resin grinding wheel and manufacturing method, which is applied in the direction of manufacturing tools, abrasives, metal processing equipment, etc., can solve the problems that the rotational strength is difficult to meet the working requirements, the service life is short, and the production efficiency is low, and the thickness and flatness can be guaranteed, and the reduction can be achieved. Production cost and the effect of reducing the loss of steel

Inactive Publication Date: 2010-09-29

SAINT-GOBAIN ABRASIVES (SHANGHAI) CO LTD +2

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Cutting discs and grinding wheels made by this method have a molding density of 2.1g / cm 3 Below, the gyration strength is difficult to meet the work requirements, and the service life is short. Usually, a cutting blade can only cut 60-85 tons of bars with a diameter of 60mm. At the same time, the production efficiency of the existing production methods is also low.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

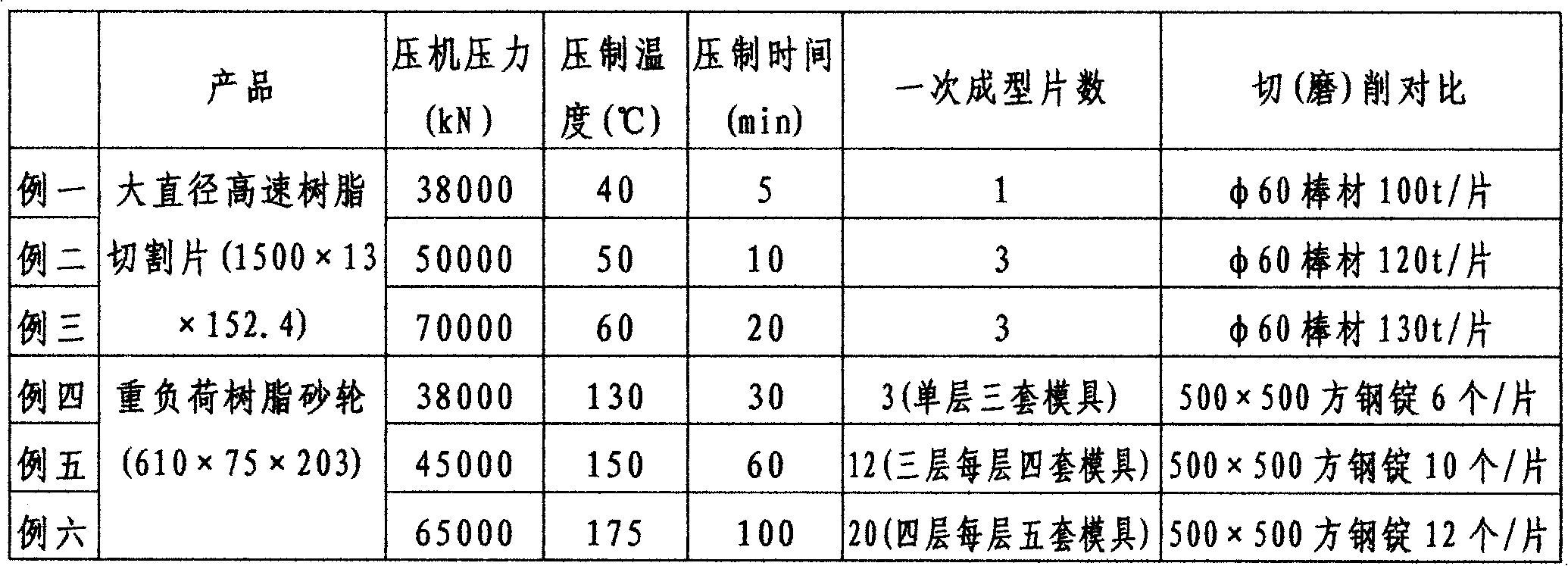

[0008] Further illustrate the present invention by embodiment, list is as follows:

[0009]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention discloses a method for manufacturing large-diameter high-speed resin cutting slice and heavy-load resin abrasive wheel. The improvement of the invention is that the pressing of blank is executed on a presser with pressure of 32000-72000KN, and the pressing time is 5-120min. The pressing temperature is preferably 40-180 DEG C. The pressing time is preferably 5-20min to the large-diameter high-speed resin cutting slice. The pressing time is preferably 30-120min to the heavy-load resin abrasive wheel. A plurality of layered placement mold modes can be adopted for pressing, and 3-20 pieces of large-diameter high-speed resin cutting slice or heavy-load resin abrasive wheel are pressed each time. The manufacturing method of the invention remarkably increases the pressing pressure and is matched with appropriate pressing time and pressing temperature. The flowing, fusing and polymerization performances of material in pressing procedure are increased. The product densityand revolving intensity are increased thereby effectively increasing the cutting performance and service lifetime, increasing the production efficiency and guaranteeing the quality stabilization.

Description

technical field [0001] The invention relates to a method for making a large-diameter high-speed resin cutting sheet for high-temperature and high-speed cutting of steel and a heavy-duty resin grinding wheel for heavy-duty grinding of steel. Background technique [0002] The diameter is between 1250-1800mm, and the line speed is between 80-120m / s, that is, the large-diameter high-speed resin cutting disc and the heavy-duty resin grinding wheel have a very high impact on the molding density and gyration strength of the product due to their special working conditions. requirements. The pressing process in the existing production method of this type of product is completed on a press with a pressure of 16,000-31,000KN, the pressing temperature is normal temperature or high temperature, and a single set of molds is used, that is, only one grinding wheel blank can be pressed at a time. Cutting discs and grinding wheels made by this method have a molding density of 2.1g / cm 3 Belo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B24D18/00B24D3/28

Inventor 黄敬民

Owner SAINT-GOBAIN ABRASIVES (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com