Method for extending rolled on-line quenching cooling region to cooling bed

A technology of cooling area and cooling bed, which is applied in the field of quenching in the field of metal heat treatment technology, can solve the problems of insufficient quenching cooling interval, inconsistent quenching cooling intensity and quenching cooling time, achieve consistent cooling effect, avoid quenching and cooling conditions, and solve the problem of cooling Effects of Insufficient Intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

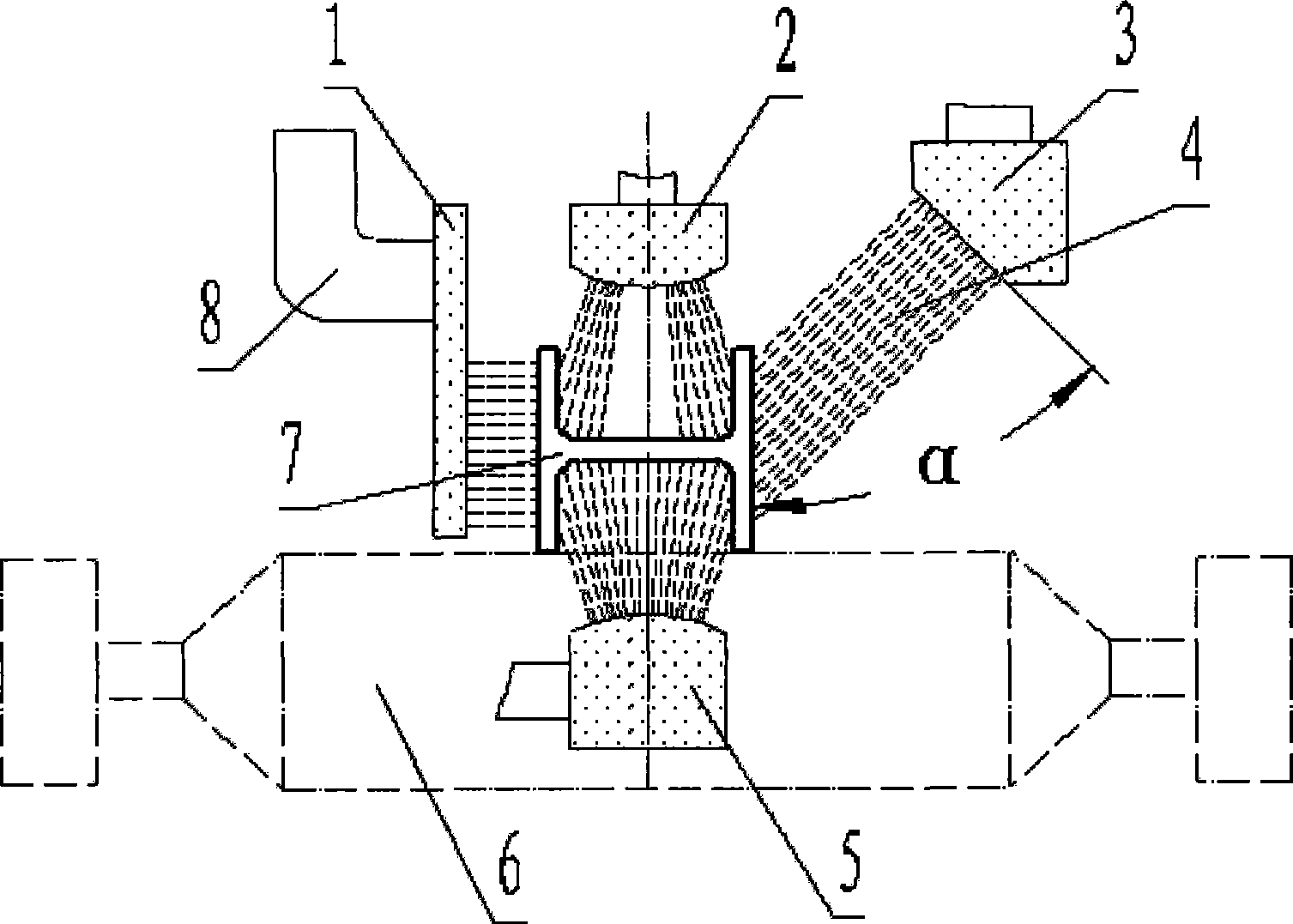

[0015] The processed product object of this example is H-beam. The size of H-beam is 338mm in height, 323mm in width, and the thickness of flange and web is 30.5mm. The movement speed of H-beam on the roller table after finishing rolling is 3m / s.

[0016] First, 6 sets of quenching and cooling covers are set between the 9m-long quenching and cooling space between the finishing mill and the cooling bed, and the mutual spacing is 1.5m. The quenching and cooling covers are designed according to the shape of H-shaped steel. It is composed of an upper spray cover, a lower spray cover, a left spray cover and a right spray cover. In order to ensure that the H-shaped steel passes through the quenching and cooling cover smoothly on the roller table, the left water spray cover and the right water spray cover are parallel to the flange of the H-shaped steel, and are about 100mm away from the outer surface of the H-shaped steel flange. The distance between the water spray surface and the ...

Embodiment 2

[0021] The processed product object of this example is steel rail, the model is 110 rail, and the movement speed on the roller table after finishing rolling is 3m / s.

[0022] First, 8 sets of quenching and cooling covers are set between the two roller tables with a 12m long reserved quenching and cooling space between the finishing mill and the cooling bed. The mutual spacing is 1.5m. The quenching and cooling covers can be designed according to the shape of the rail. The cover is made up of an upper spray cover, a lower spray cover, a left side spray cover and a right side spray cover.

[0023] In order to ensure that the rail passes through the quenching and cooling cover smoothly on the roller table, the left water spray cover and the right water spray cover are parallel to the side of the rail, and are respectively about 100mm away from the side of the rail. The size of the roller is 300mm, and the water spray surface of the lower spray cover is about 50mm lower than the r...

Embodiment 3

[0027] The product to be processed in this example is a steel plate. Firstly, a quenching and cooling cover is set between each pair of roller tables in the reserved quenching and cooling space between the finishing mill and the cooling bed. The quenching and cooling cover is composed of an upper water spray cover and a lower water spray cover. , the left spray cover and the right spray cover. The left water spray cover and the right water spray cover are parallel to the sides of the steel plate and are used for quenching and cooling the two sides of the steel plate. The upper water spray cover is used for quenching and cooling of the upper surface of the steel plate, and the lower water spray cover is used for quenching and cooling of the lower surface of the steel plate. The upper spray cover, the lower spray cover, the left spray cover and the right spray cover are respectively connected with an independent water supply pipeline through pipelines and valves.

[0028] The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com