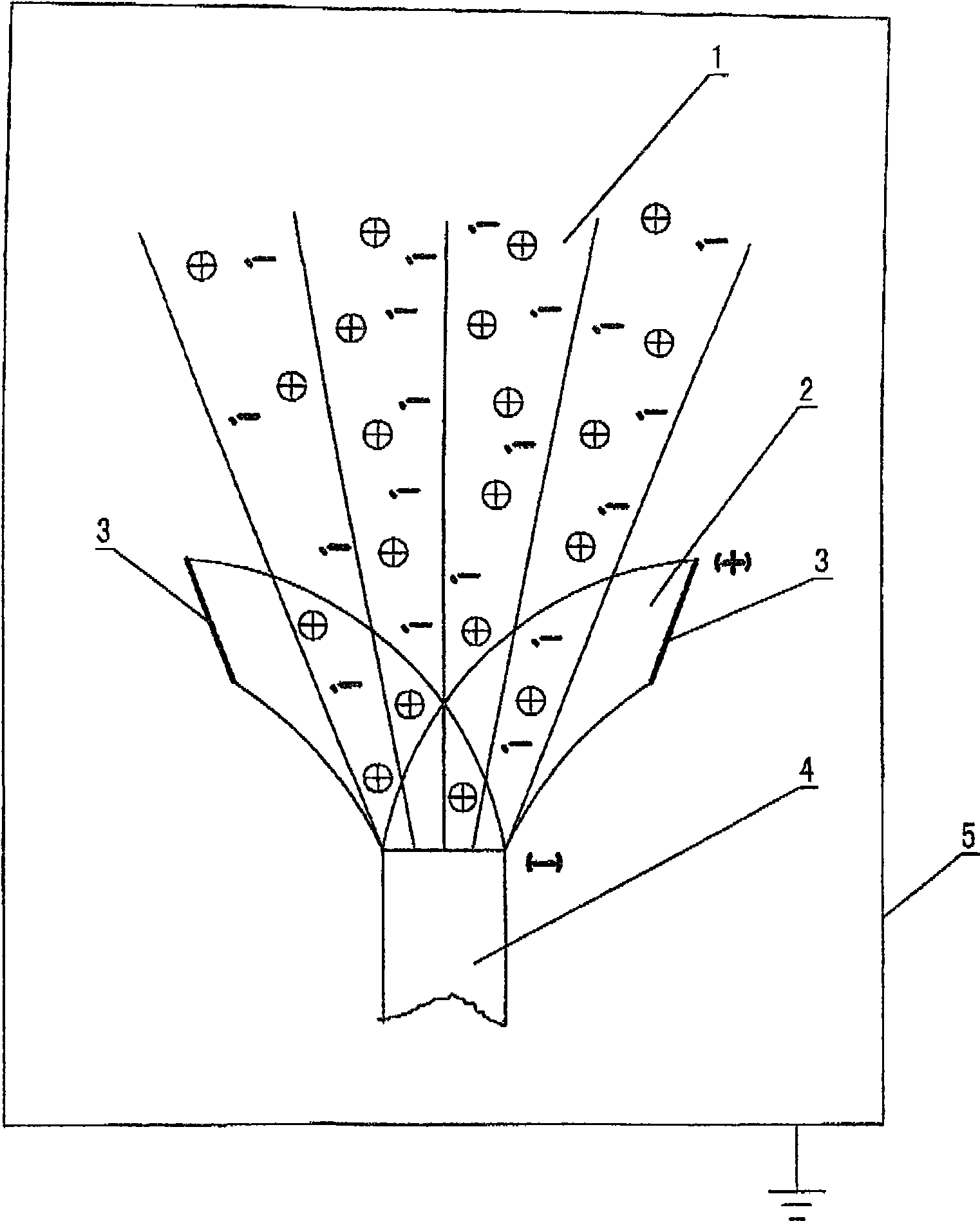

Vacuum arc plasma evaporation inonization source for non-arc spot

A plasma and vacuum arc technology, applied in the field of plasma, can solve problems such as arc spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] According to the vacuum arc plasma evaporation ionization source without arc spot of the present invention, taking the cylindrical cathode with a circular cross section as an example, it has been tested in our company's laboratory, and it is confirmed that there is no arc spot after the actual measurement of the plating process and results. , No droplets.

[0085] The first batch of 9 evaporation sources of this kind has been put into production, and they are used to assemble the environment-friendly TGN-JKDD9 ion coating machine. After the machine is put into the market in batches, it will gradually replace the existing traditional electroplating production with serious environmental pollution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com