Symmetrical multi-beam collimation laser pavement track detection system

A collimated laser and detection system technology, applied in the field of laser road rutting detection system, can solve the problems of expensive products, many laser probes, complicated technology, etc., and achieve the effect of eliminating errors, reducing damage, and eliminating the influence of measurement accuracy

Inactive Publication Date: 2009-07-08

CHANGAN UNIV

View PDF0 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Among several technologies for quickly detecting road ruts, the laser rotating mirror scanning method is used. Due to its complicated technology and expensive product prices, it is not used much at present; multiple laser displacement sensors are used to detect ruts, although they are arranged on the cross section. When there are more laser displacement sensors, the detection accuracy can meet the actual requirements, but due to the use of more laser probes, the product cost of this method is higher

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

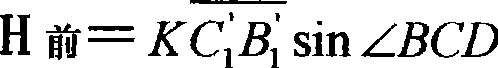

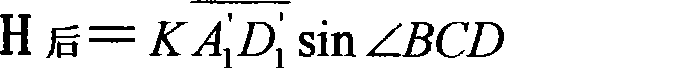

The invention relates to a symmetrical multiple collimated layers pavement rut detection system used for detecting the rut indexes on pavement, which consists of two downward shooting cameras disposed on both sides of the rear upper part of the system carrying vehicle, a plurality of rear lasers transversely installed on the rear outer lower part of the carrying vehicle body side by side through foldable door shaped rods and front layers installed on the inner lower part of the system carrying vehicle body side by side through transverse connection rods. In practical work, the front and rear lasers send out collimated layer beams to the inclined downwards direction respectively which projects on pavement to form laser scattered lines, and the information of depth, left and right and size of the rut on the pavement can be obtained through the shooting camera imaging, digital image processing and calculating. Compared with the current technologies, By using a plurality of collimated layers instead of high bright line laser, the invention can reduce the damage to human eyes caused by the laser, increases the safety in pavement rut detection by laser, while greatly increases the service life of the detection system.

Description

Technical field The invention belongs to the technical field of photoelectric measurement systems, and relates to a photoelectric detection system for object displacement or surface shape and related quality indicators, in particular to a laser road rut detection system that can be used to detect road rutting indicators. Background technique The detection index of road rut is an important content of road maintenance management. The unevenness of the road rut, especially the accumulation of water in rainy weather, often poses a great safety hazard to road traffic. It is easy to cause the driving vehicle to slip, and serious rutting will make it difficult for vehicles to change lanes. Affected the comfort and safety of driving. Therefore, it is very important to quickly detect the rutting condition of the road to provide accurate road surface condition analysis indicators for road maintenance. In the past, the well-known pavement rutting detection techniques mainly include manual ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E01C23/01G01B11/22G01B11/00

Inventor 宋宏勋马建马荣贵韩毅樊江顺申福林李平

Owner CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com