Differential current-to-voltage conversion

A technology of differential current and voltage conversion circuit, applied in the direction of differential amplifiers, electrical components, charge amplifiers, etc., to achieve the effect of improving the power supply rejection ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In the following paragraphs, the differential current-to-voltage conversion circuit 10 is described in the context of a proximity sensor comprising a light emitter (eg, a VCSEL or LED) and a light detector (eg, a photodiode). However, the differential current-to-voltage conversion circuit 10 may be used in other applications, including applications where it is desired to sense relatively small current signals.

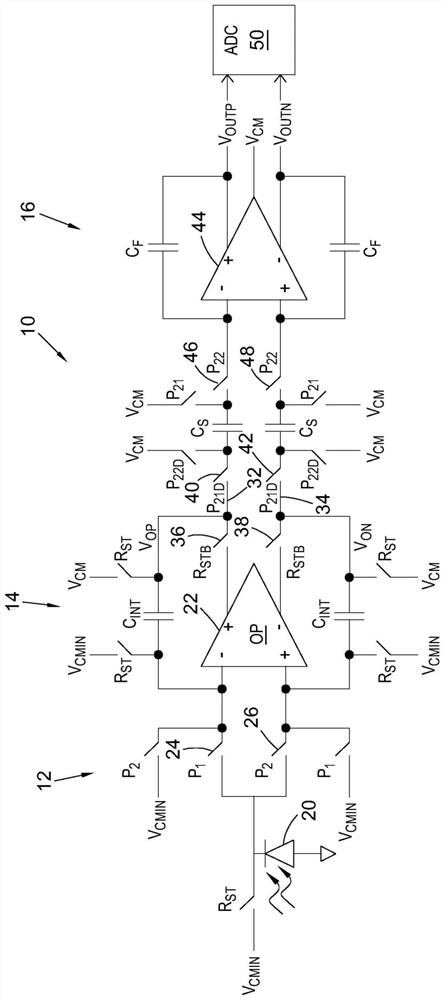

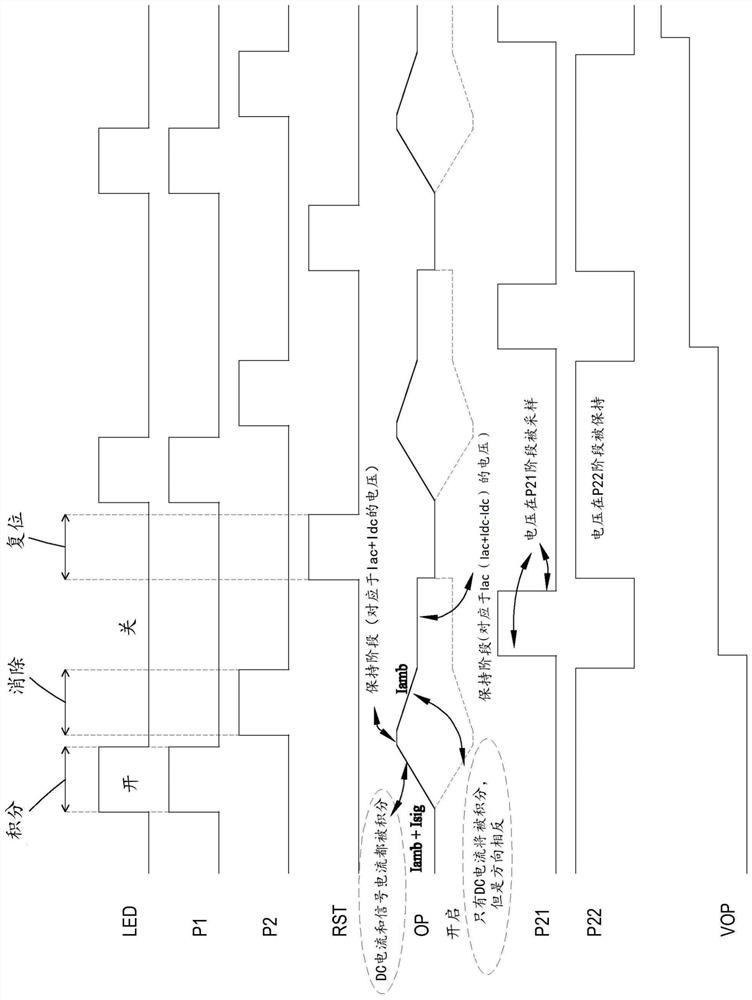

[0016] Such as figure 1 As shown, differential current-to-voltage conversion circuit 10 includes an input sampling stage 12 , a differential integration and DC signal cancellation stage 14 , and an amplification and accumulator stage 16 . Circuit 10 may be fabricated, for example, as an integrated semiconductor circuit using standard digital CMOS design and fabrication techniques.

[0017] The input sampling stage 12 is configured to receive a current signal from a current generating device, which in the example shown is a photodetector (eg a photodiode) 20 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com