Curing method for fast forming crust layer on yard surface

A solidification method and hard shell technology, which can be used in soil protection, construction, and infrastructure engineering, etc., can solve problems such as low strength and shorten the time for foundation treatment, and achieve uniform properties, stable strength, and low processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

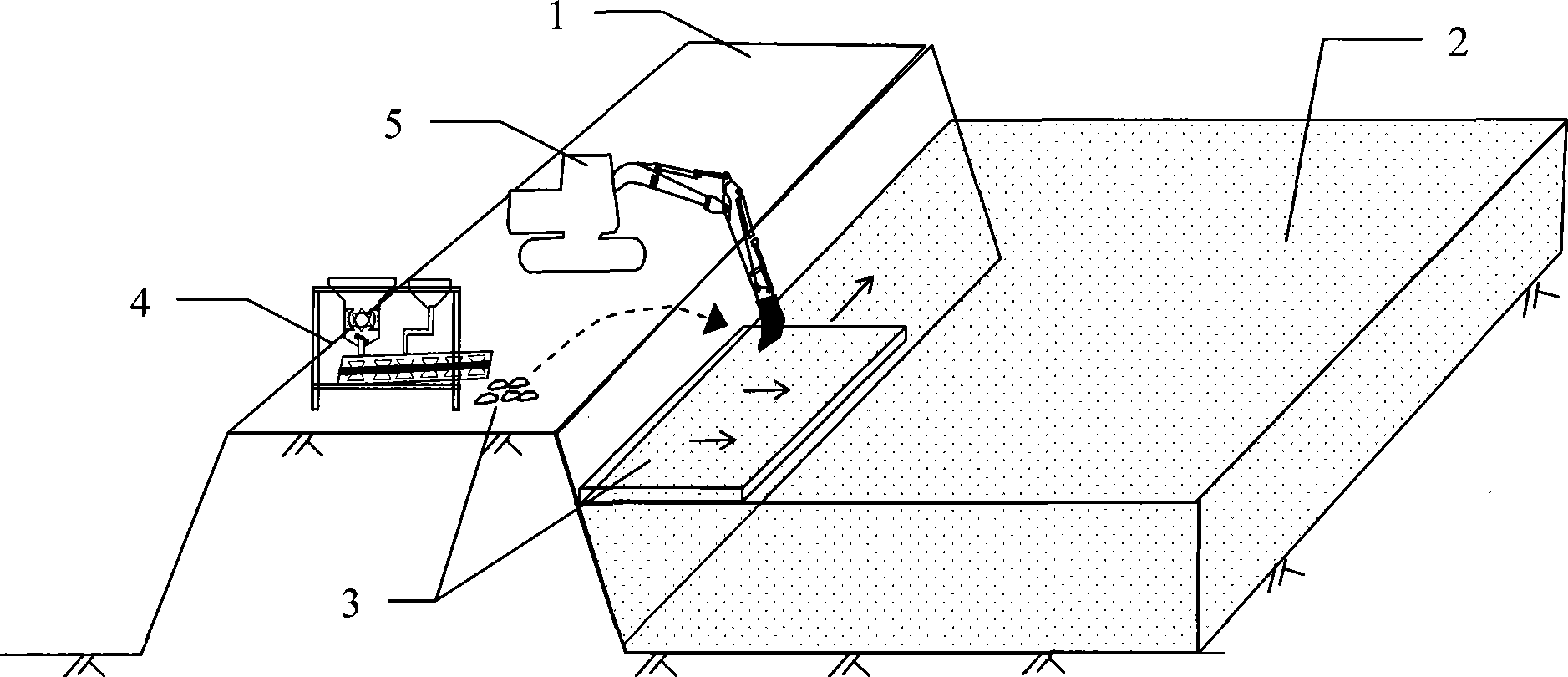

[0020] A kind of curing method that quickly forms hard shell layer on the surface of stockyard, this method comprises the following steps:

[0021] (1) start the sludge curing machine 4, and mix and stir the sludge and solidified material (also can add lightweight materials such as EPS particles, crushed rubber particles, etc.);

[0022] (2) utilize excavator 5 to lay on the yard surface after stirring;

[0023] (3) After the solidified silt has hardened after laying (about 1 to 2 days), manual or light laying machinery can be driven onto the hard shell layer, and then laid forward in sequence until the entire silt yard is covered.

Embodiment 2

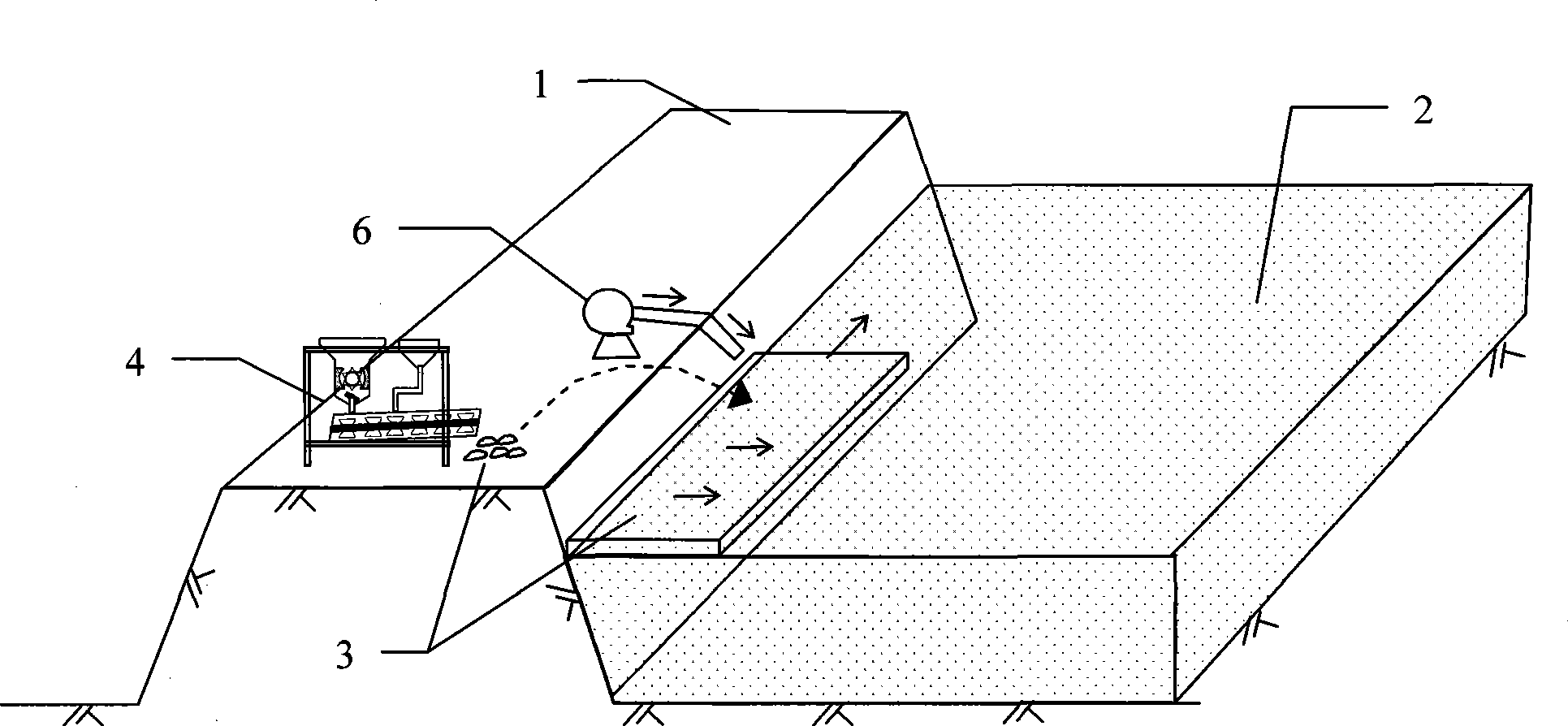

[0025] A kind of curing method that quickly forms hard shell layer on the surface of stockyard, this method comprises the following steps:

[0026] (1) start the sludge curing machine 4, and mix and stir the sludge and solidified material (also can add lightweight materials such as EPS particles, crushed rubber particles, etc.);

[0027] (2) Utilize the mud pump 6 to lay on the surface of the yard after stirring;

[0028] (3) After the solidified silt is laid and hardened (about 1 to 2 days), the construction personnel can walk on the surface of the hard shell layer laid before, and then extend the mud pump mud pipe forward and lay it sequentially until the entire silt yard Paved.

Embodiment 3

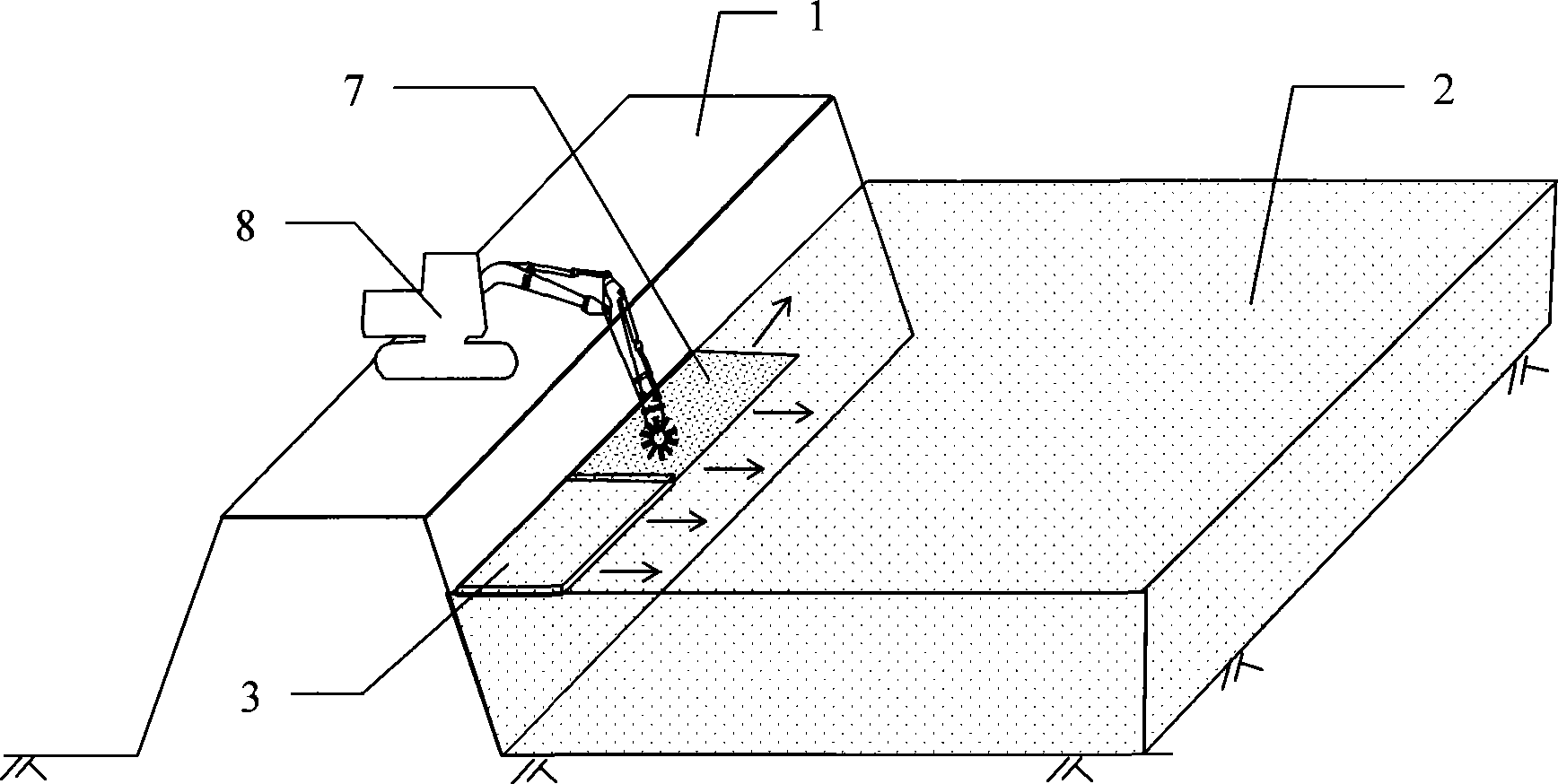

[0030] A kind of curing method that quickly forms hard shell layer on the surface of stockyard, this method comprises the following steps:

[0031] (1) manually or mechanically spread the solidified material on the surface of the mud,

[0032] (2) Utilize the in-situ sludge solidification machine 8 to mix and stir the sludge and the solidified material 7 in situ;

[0033] (3) After mixing well and waiting for the solidified sludge to harden (about 1 to 2 days), a manual or light in-situ solidification machine can be driven onto the previously laid hard shell layer, and then laid forward in sequence until the entire sludge yard is covered. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com