Nitrogen sinking type pump head

A pump head and pump body technology, which is applied in pumps, liquid variable displacement machines, machines/engines, etc., can solve the problems of high cost, large vaporization loss of liquid nitrogen extraction equipment, and complex insulation structure, etc., to achieve small vaporization loss, Easy to measure accurately, good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

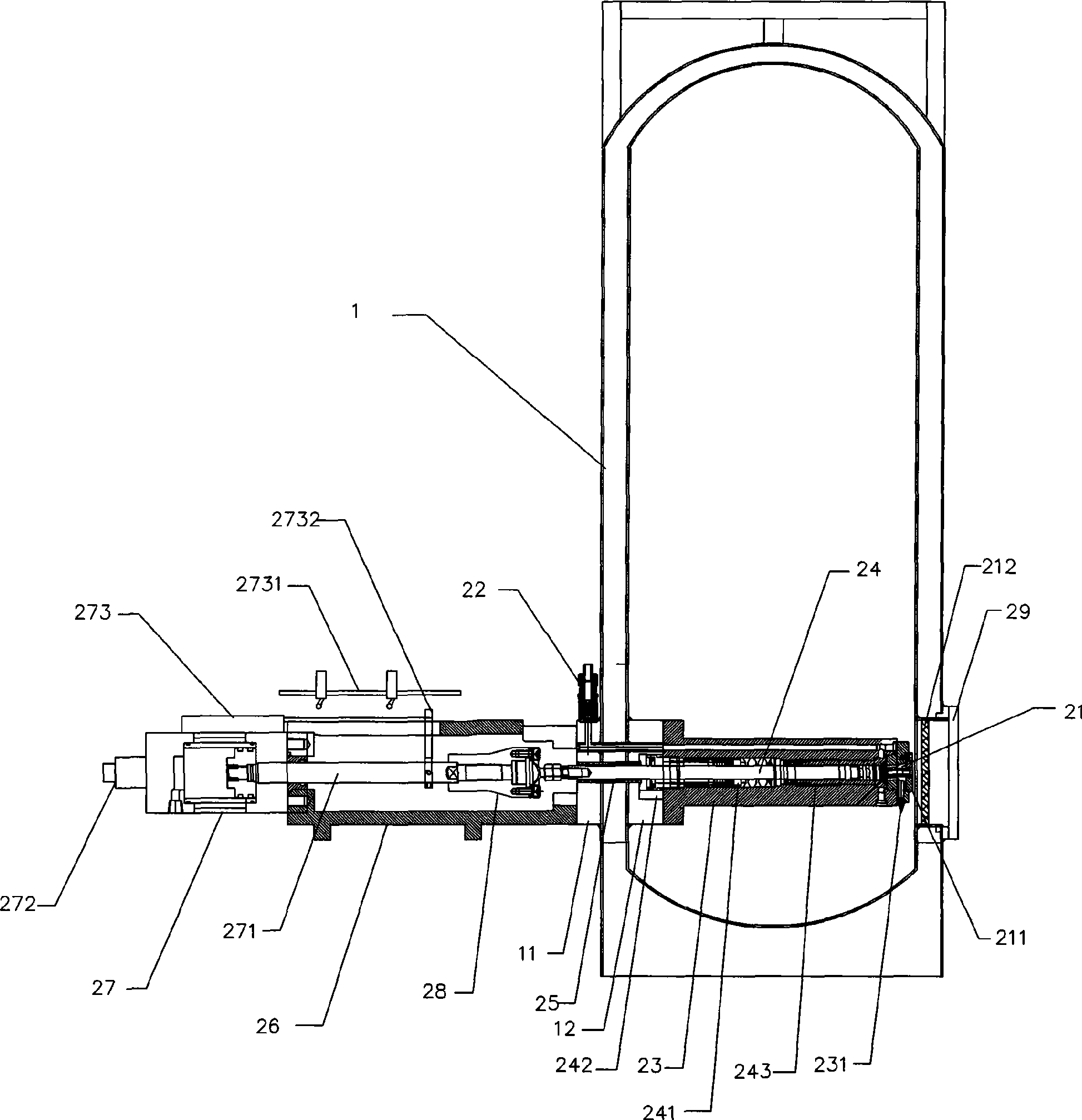

[0014] Refer to attached picture

[0015] The nitrogen sinking pump head of the present invention includes a plunger pump, the pump body of the plunger pump passes through the wall of the liquid nitrogen tank 1, and the pump body and the liquid nitrogen tank 1 at the crossing point The walls are insulated and hermetically connected, the liquid inlet 21 of the plunger pump communicates with the inner cavity of the liquid nitrogen tank 1, and the liquid outlet 22 of the plunger pump is located in the liquid nitrogen tank 1. external.

[0016] The wall of the liquid nitrogen tank 1 is provided with an outer welding flange 11 and an inner welding flange 12, and the housing 23 of the plunger pump is connected to the inner welding flange 12, and the plunger The first piston rod 24 of the pump passes through the wall surface of the liquid nitrogen tank 1 through the heat insulating guide sleeve 25; The power cylinder set 27 is installed on the pump cylinder connecting seat 26 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com