Connector for helically reinforced pipe

A tube and helical technology, applied in the field of improvement of the structure of the rotary spiral reinforced pipe joint, can solve problems such as troublesome work, and achieve the effects of reducing labor intensity, improving work efficiency and having a large diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

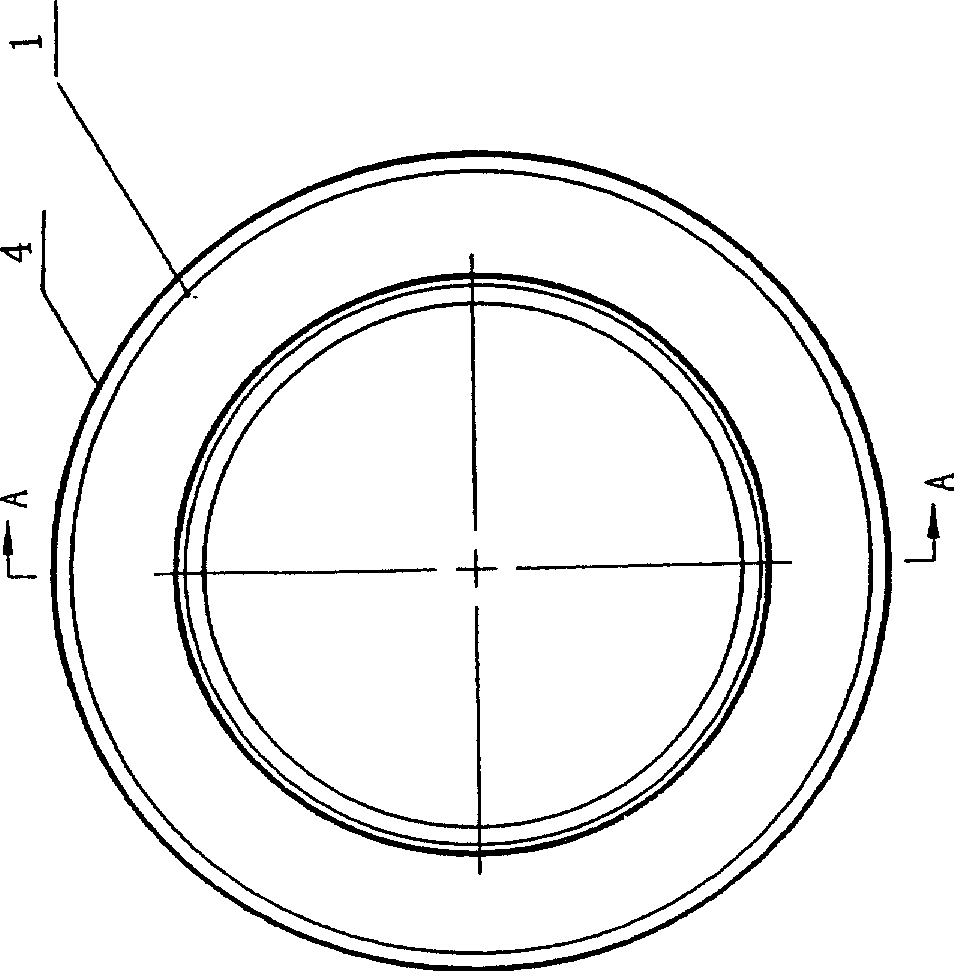

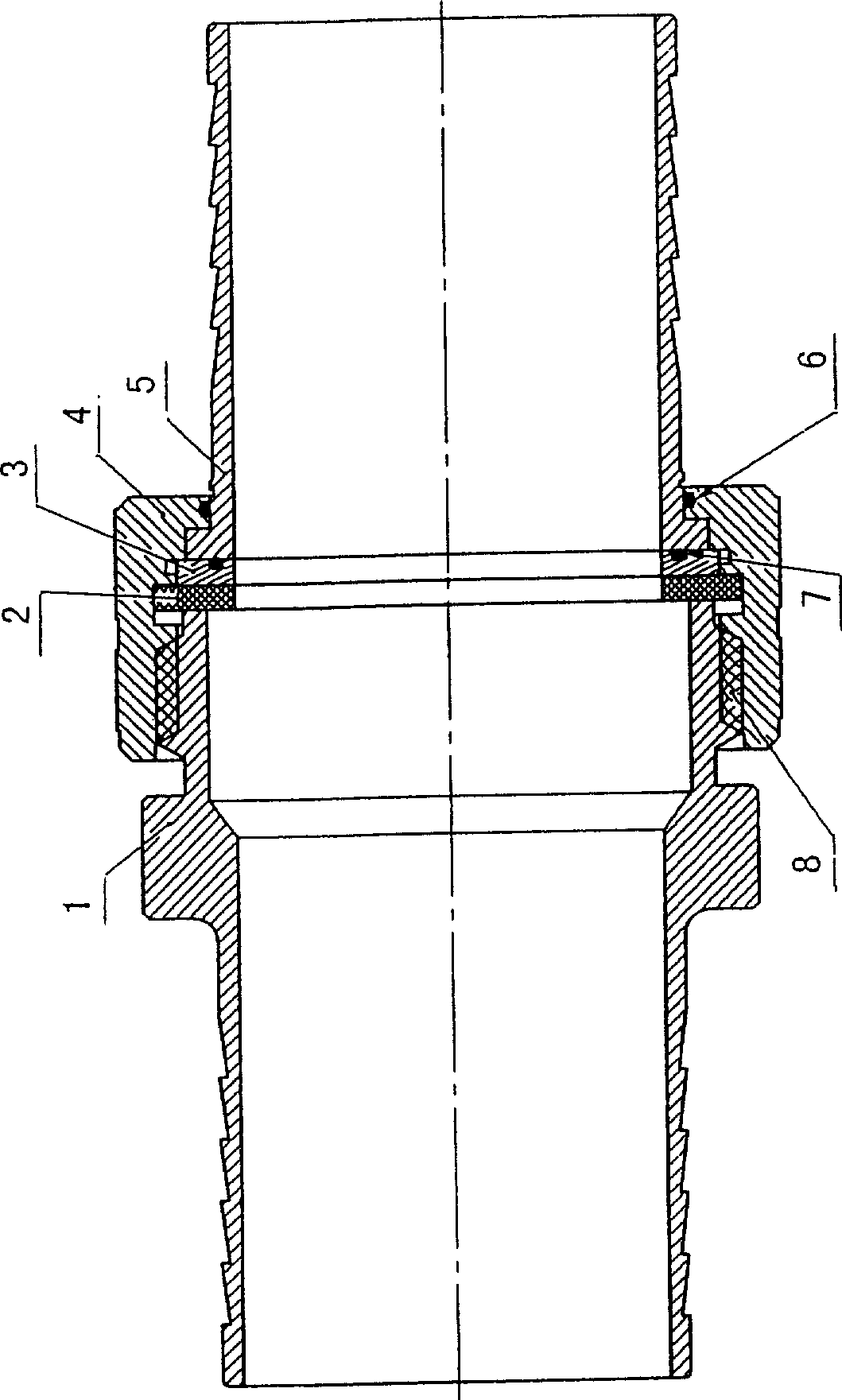

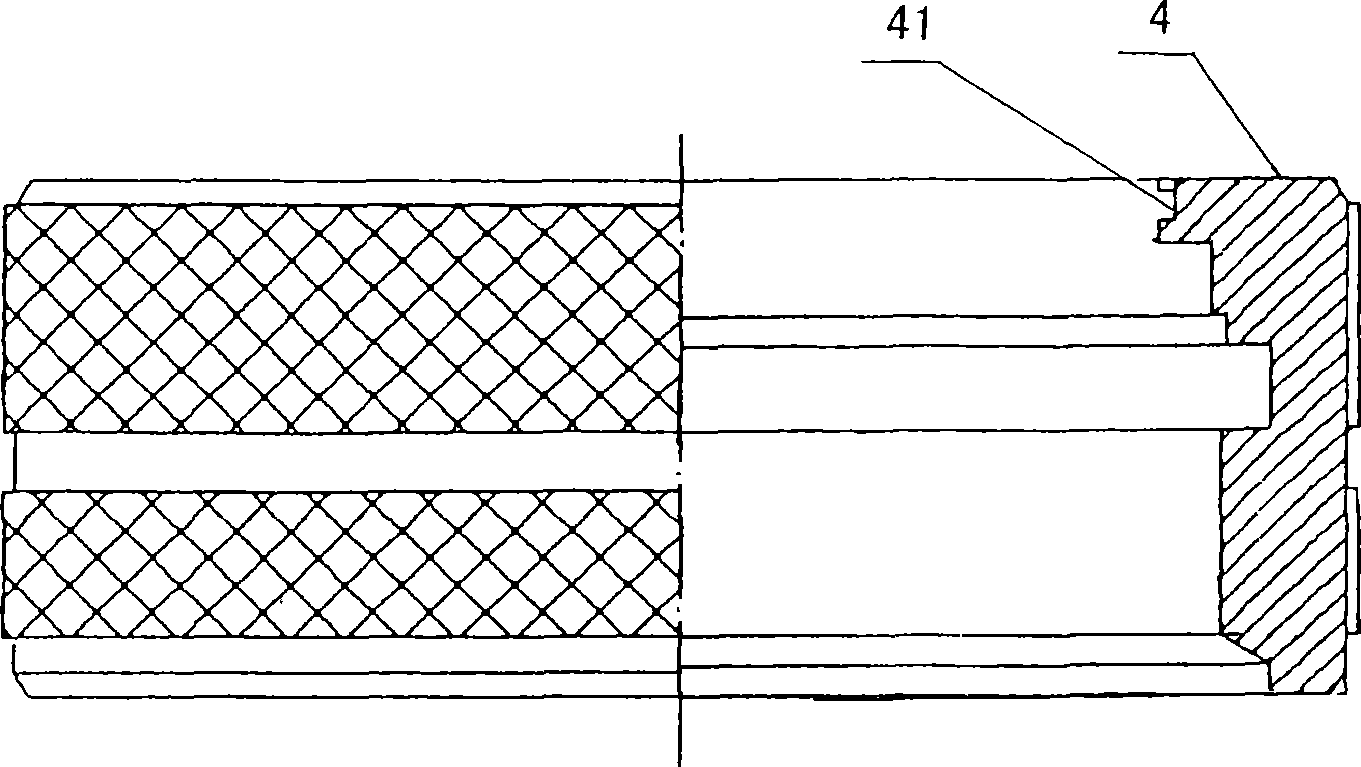

[0013] like figure 1 , figure 2 The pipe joint shown has a neutron 5 with an inner diameter of 69 mm, a body 1 docked with the neutron, and an inner diameter of 69 mm. The neutron and the body are connected by a nut 4 sleeved on the outside of the body and the neutron. The connecting end of the cap 4 and the neutron 5 adopts an inverted L-shaped socket structure, and the connecting end of the nut 4 and the body 1 adopts an internal and external screw thread 8 connection structure; on the small diameter at the outermost end of the nut 4, it cooperates with the outer wall of the neutron There is a radial groove 41 on the surface (see image 3 As shown), in the radial groove, a nut ○-shaped sealing ring 6 that is sealingly matched with the outer wall of the neutron is arranged to make it play a sealing role between the nut and the neutron; Between the two end faces of the front end of the outer thread of the body, there is an annular metal gasket 3 made of aluminum. The inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com