High-precision smooth-running automobile chassis dynamometer flywheel set system

A technology of smooth operation and automobile chassis, which is applied in the direction of vehicle testing, machine/structural component testing, and vehicle traction/propulsion power measurement. It can solve problems such as large moment of inertia, unstable work, and bending deformation of the main shaft. Effects of high simulation quality accuracy, easy and flexible handling, and small axial dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The structure of the present invention will be described in further detail below in conjunction with the embodiments given in the accompanying drawings.

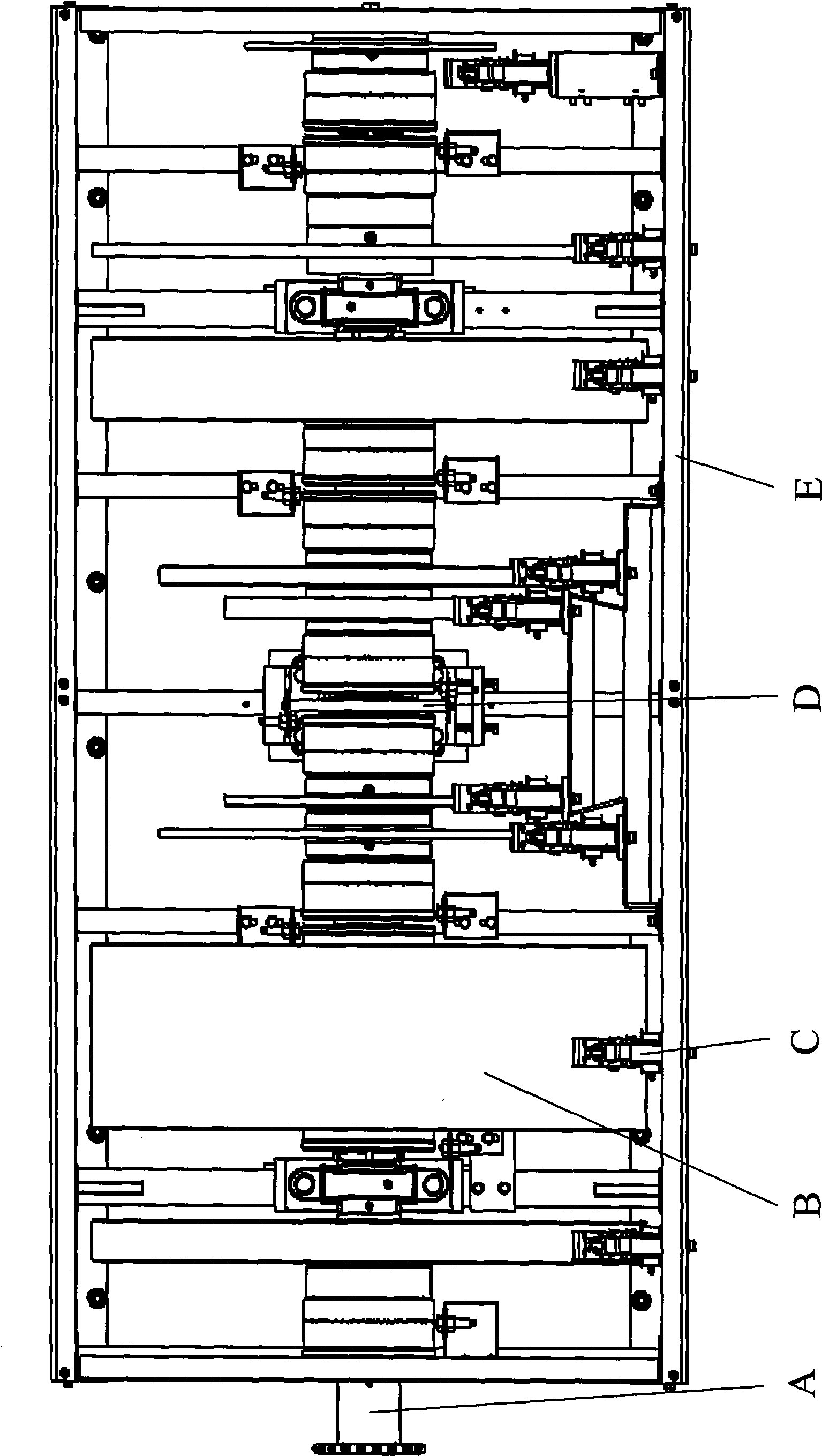

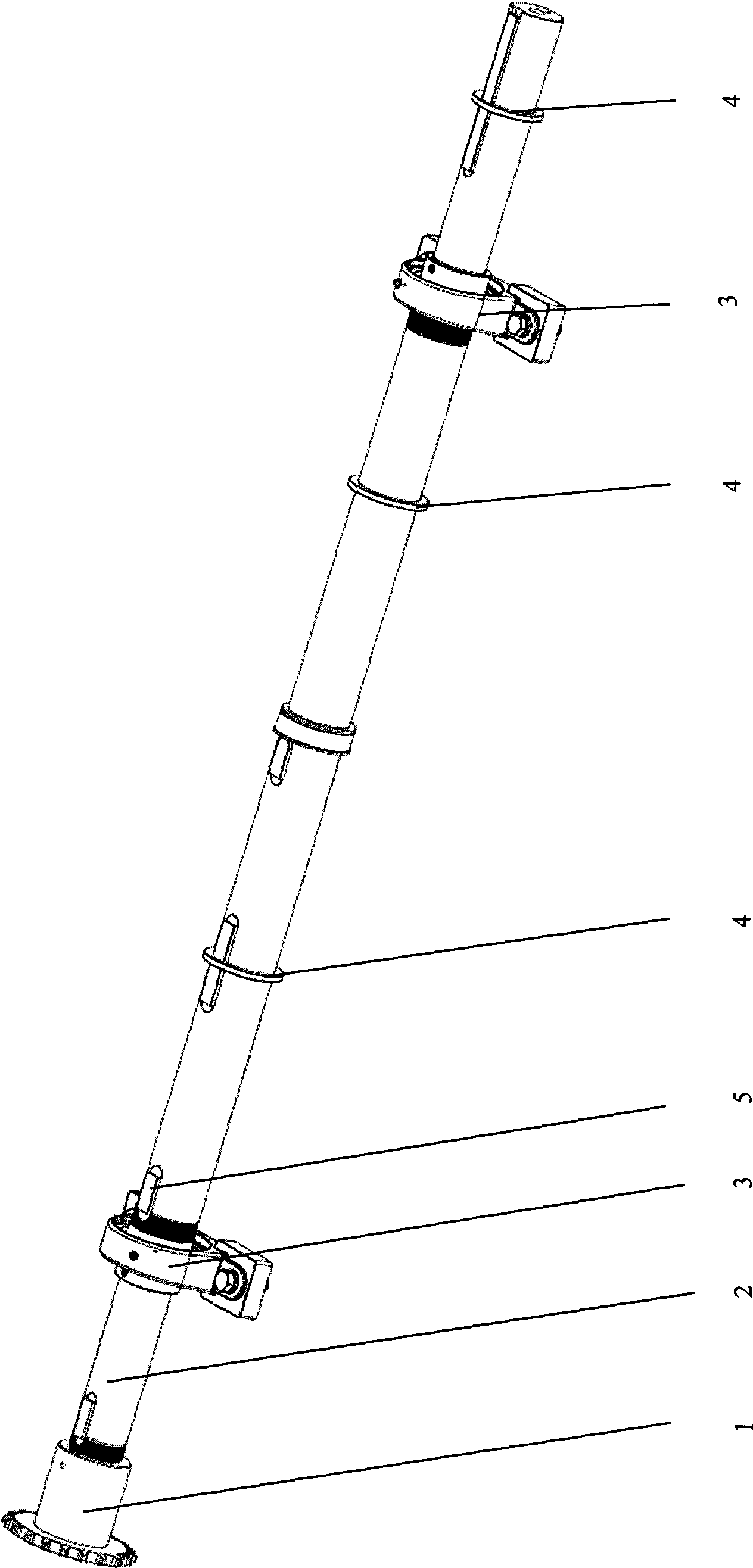

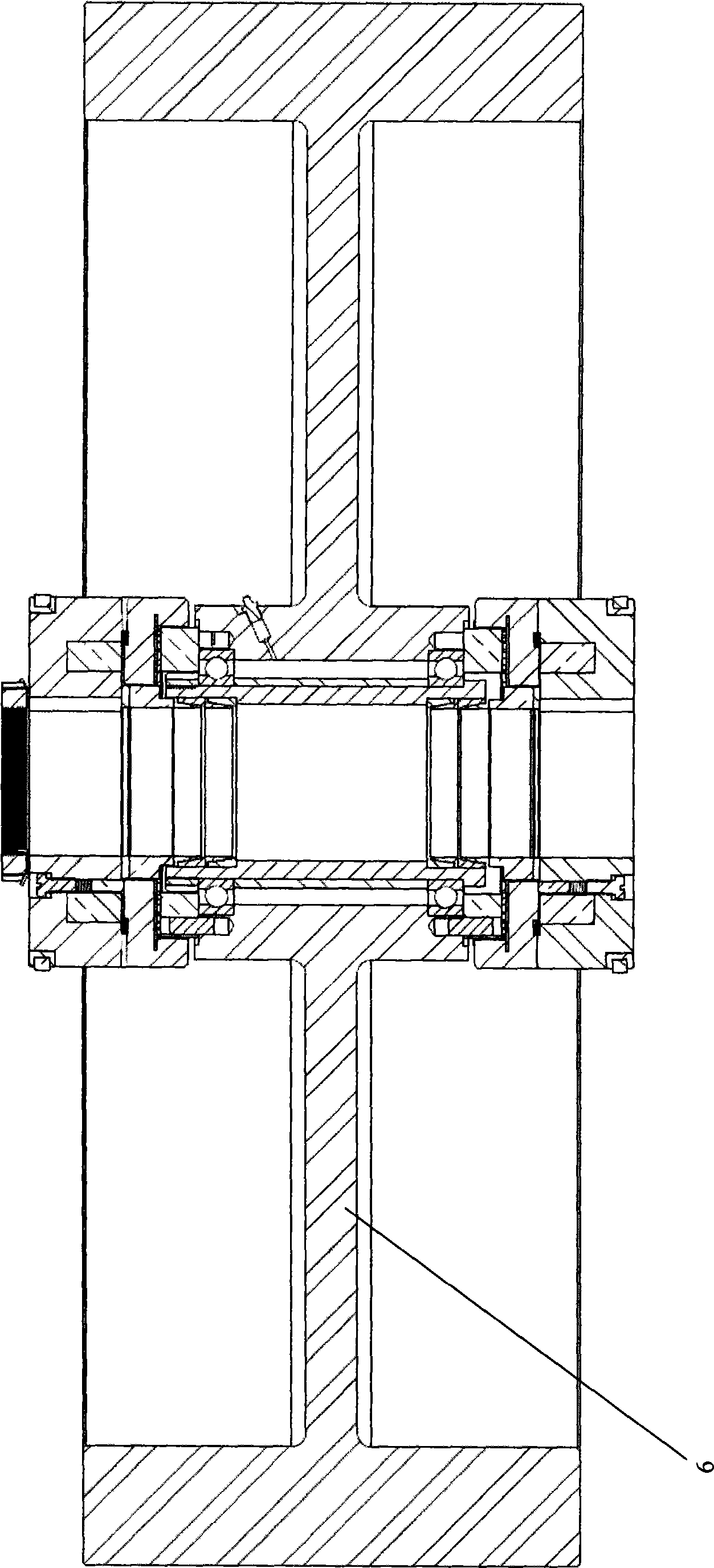

[0042] refer to figure 1 , a high-precision and smooth-running automobile chassis dynamometer flywheel system is characterized in that it consists of a main shaft assembly A (see figure 2 ), flywheel assembly B (see image 3 , Figure 4 ), brake assembly C, spindle stabilizer assembly D (see Figure 6 ), frame E (see Figure 7 ) consists of five parts. The frame E is fixedly connected to the foundation through the feet 35, the main shaft assembly A is bolted to the frame E through the bearing seats 3 at both ends, and the flywheel assembly B is composed of multiple sets of clutches and flywheels with different moments of inertia. On the assembly A, the spindle stabilizer assembly D is set on the spindle through the inner ring of the roller bearing 29, and the brake assembly C is bolted to the frame E through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com