Manufacturing process of polyolefin resin film

A polyolefin-based resin and a technology for a manufacturing method, which can be applied to flat products, other household appliances, tubular articles, etc., can solve the problems that the transparency of the film may not be satisfactory, and the cost of the molding device is satisfactory.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

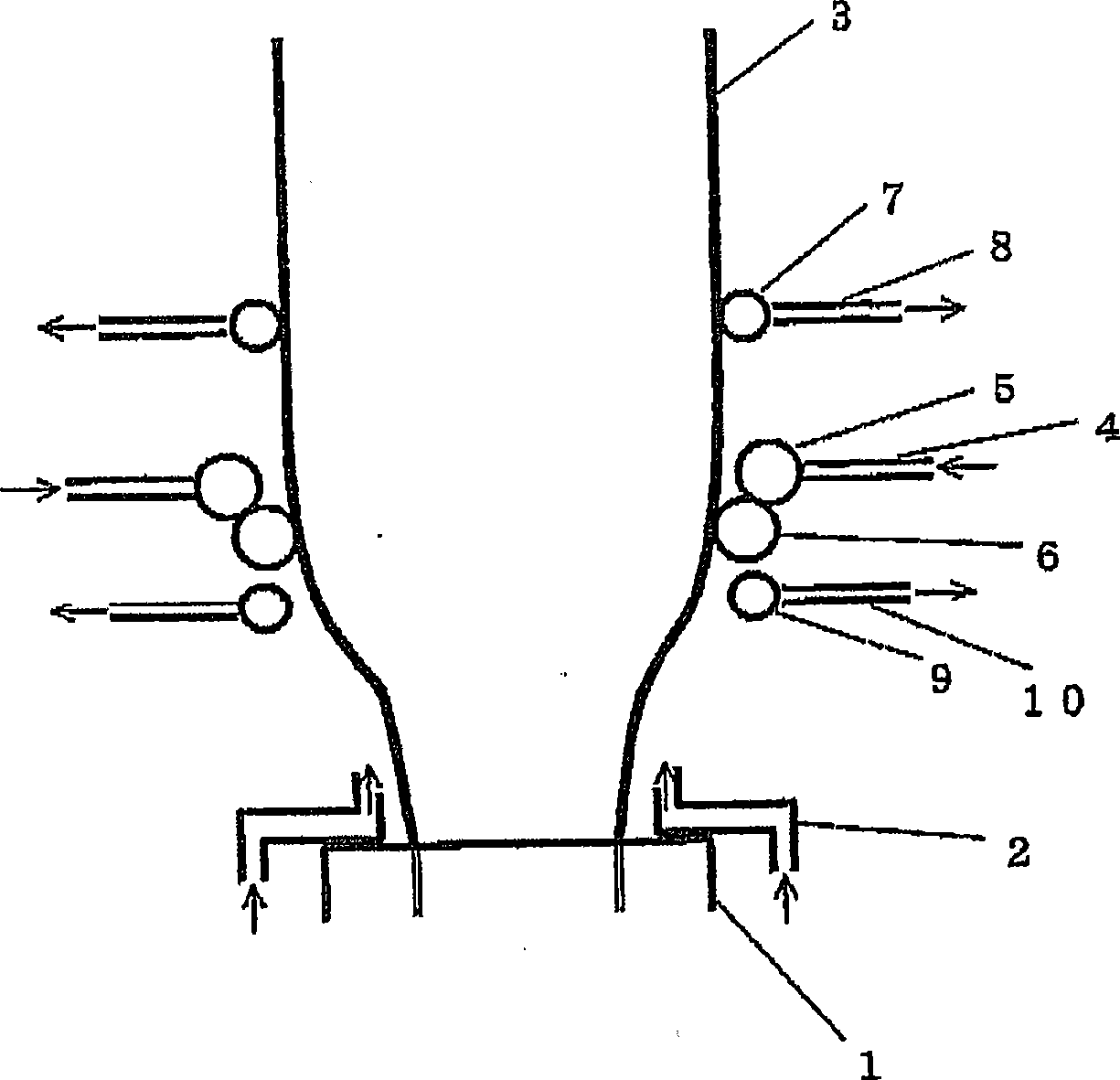

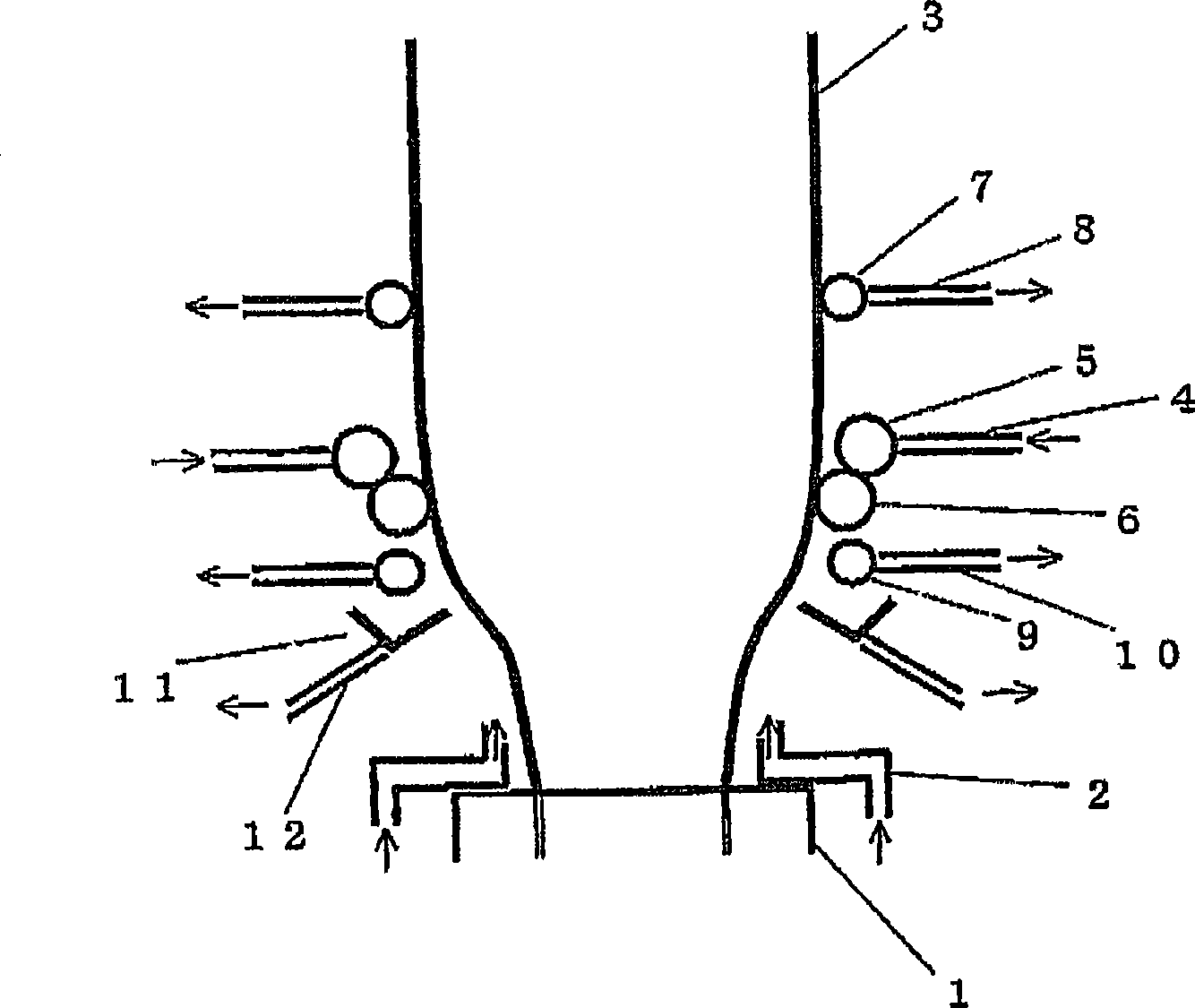

[0052] Installed in an upward-facing air-cooled blow molding device manufactured by Placo with a 50 mmΦ extruder, a ring die (lip diameter 125 mm, lip opening 2.0 mm), blowing device, and pulling device figure 1 The water cooling device shown is a water cooling device comprising a water supply device having a water supply pipe, a water supply ring, and a contact ring for water supply, and a drainage device having a downstream water recovery ring, a downstream drain pipe, an upstream water recovery ring, and an upstream drain pipe. device. A polyester nonwoven fabric sheet with a width of 30 mm (Nitoms Co., Ltd. Strong Dew Condensation Water Absorbent Tape 30 Silver E101) as a water absorbing material was wound around a contact ring for water supply and used.

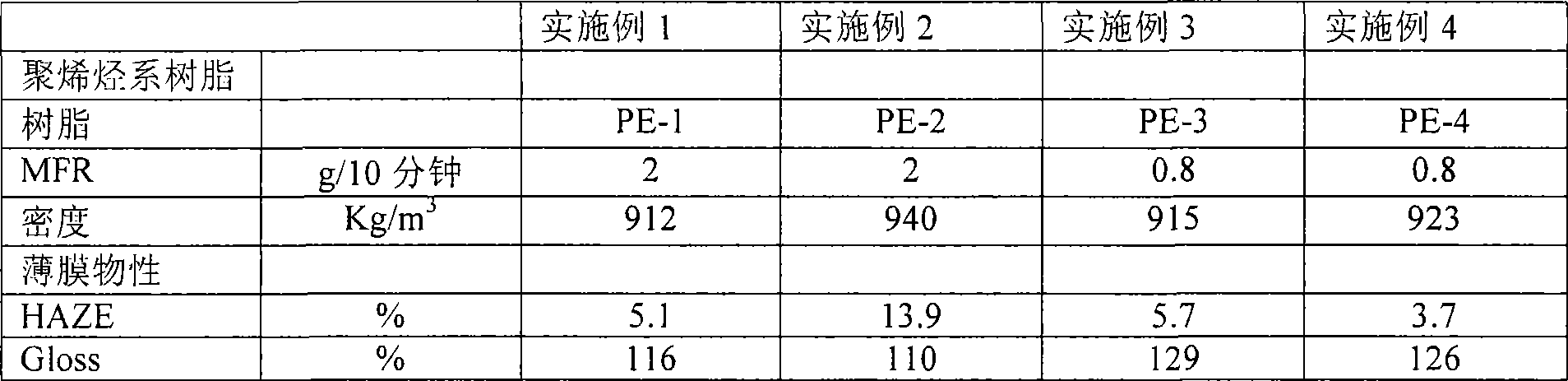

[0053] The ethylene·1-hexene copolymer (sold by Sumitomo Chemical Co., Ltd., manufactured by Japan Evolue Co., Ltd., trade name: Sumikathene E FV203 (hereinafter referred to as PE-1)) produced by a metallocene catalyst i...

Embodiment 2

[0055] Except for using an ethylene-1-hexene copolymer produced by a Ziegler catalyst (manufactured by Sumitomo Chemical Co., Ltd., trade name: Sumikathene α CS8051 (hereinafter referred to as PE-2)) instead of PE-1, the same as in Example 1 operate. Table 1 shows the evaluation results of physical properties of the obtained film.

Embodiment 3

[0057] Using an ethylene-1-butene copolymer produced by a Ziegler catalyst (manufactured by Sumitomo Chemical Co., Ltd., trade name: Sumikathene L CL1079 (hereinafter referred to as PE-3)) instead of PE-1, the processing temperature was 190°C, Except for this, it was carried out in the same manner as in Example 1. Table 1 shows the evaluation results of physical properties of the obtained film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com