System and method for realizing three-dimensional storage and sorting

A three-dimensional, box-body technology, applied in the field of warehousing, can solve the problems of increased conveying equipment, large warehouse area, affecting the overall appearance of the warehouse, and achieve the effect of reducing storage costs, reducing area, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

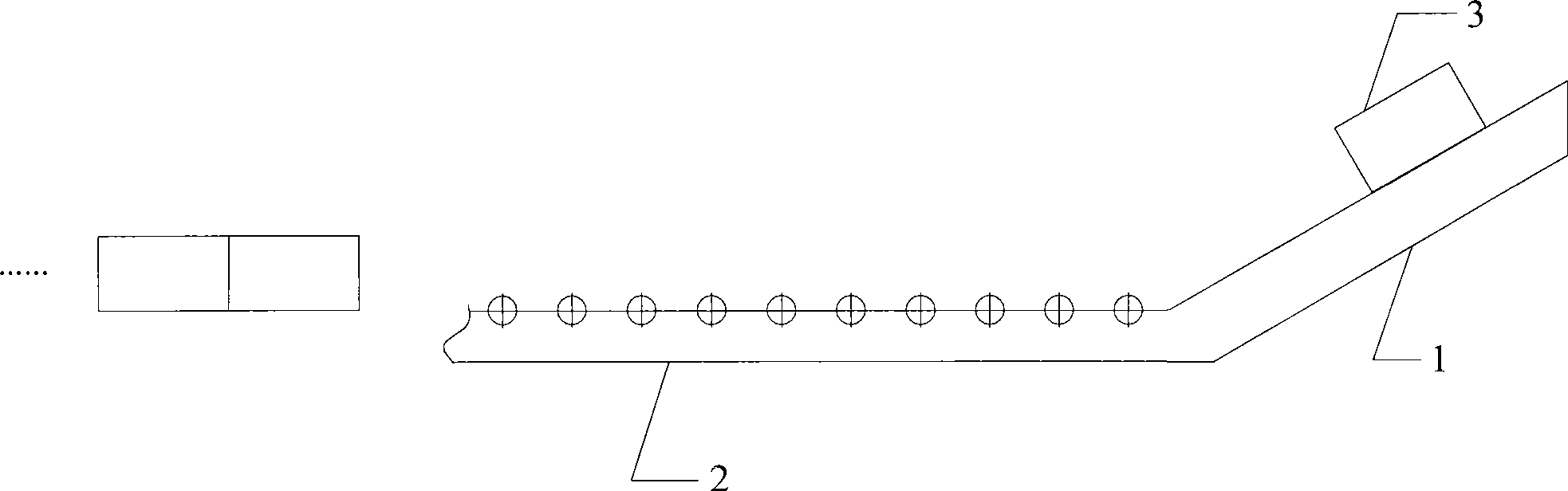

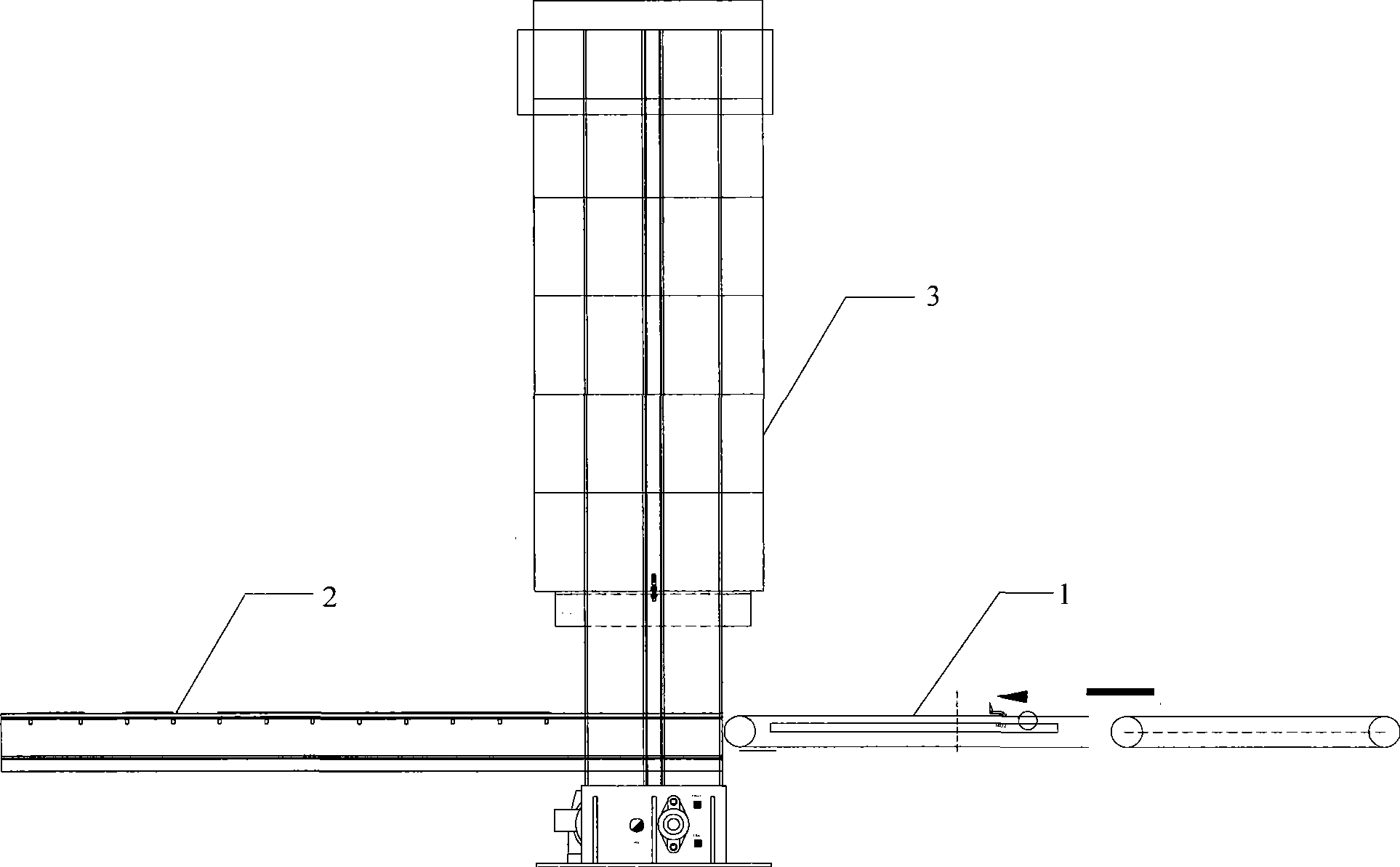

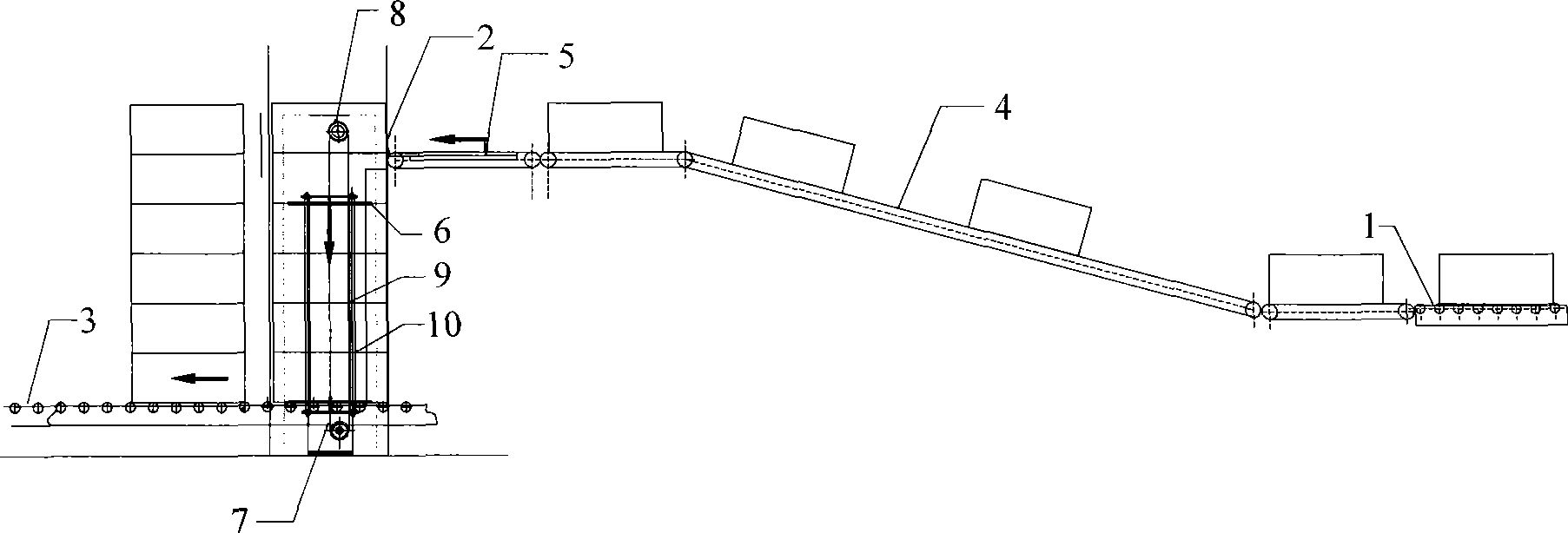

[0025] In order to solve the problems existing in the prior art, the present invention proposes a solution to change the traditional planar storage into a three-dimensional storage: transport the boxes to be stored to the stacker for stacking, and the stacking is done by the photoelectric switch When it is detected that the stacking of the boxes is completed, the conveyor line is controlled by a programmable logic controller (PLC) to transport the stacked boxes to the storage for storage; When the box is obtained from the warehouse, the box in the storage is transported to the depalletizer; the photoelectric switch detects the depalletizer, and when it is detected that the box reaches the depalletizer, the depalletizer disassembles the Palletizing, and then the conveying line is controlled by the PLC to transport the unstacked boxes out, thereby reducing the warehouse floor space occupied by the box storage, reducing storage costs, and improving work efficiency.

[0026] In or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com