Efficient loading method for digger

An excavator, high-efficiency technology, applied in the operation method of excavator/dredger, loading/unloading, earth mover/shovel, etc., can solve the problem of increasing fuel consumption and wear of excavators, prolonging loading time, and easily causing congestion and other problems, to achieve the effect of improving the efficiency of excavation operations, reducing fuel consumption and wear, and reducing the angle of rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific embodiment:

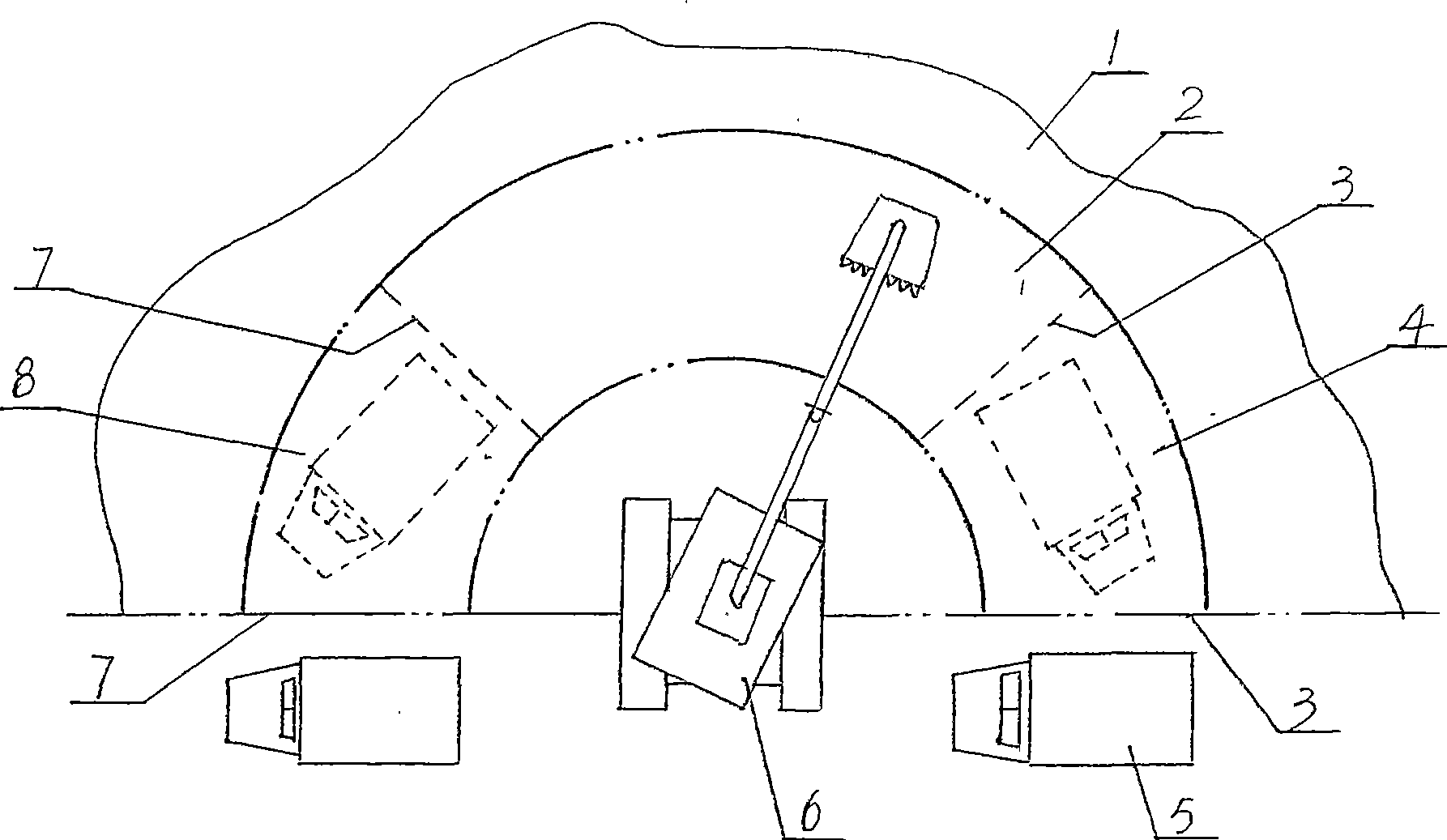

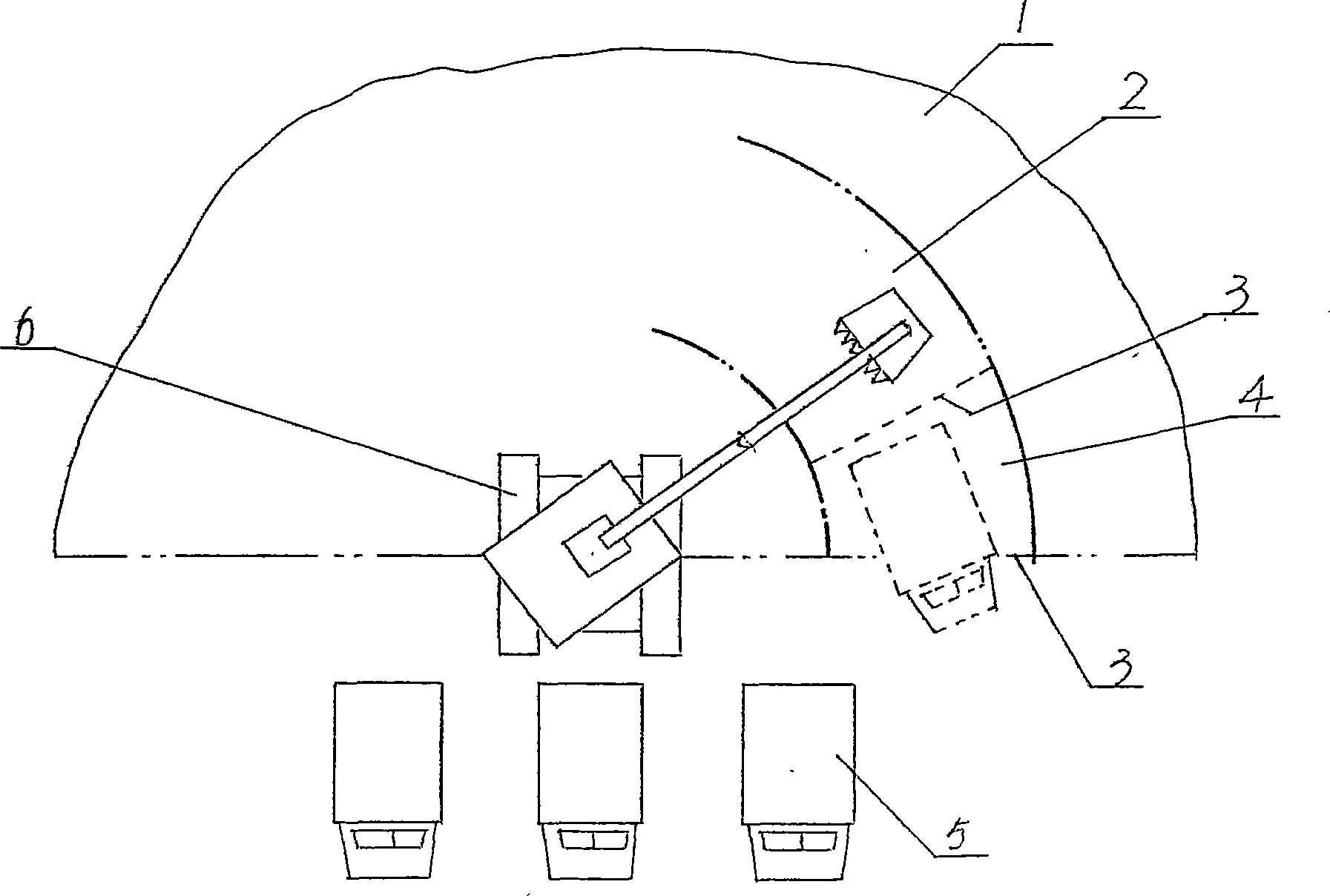

[0015] like figure 1 As shown: Park the excavator 6 on the edge of the area to be excavated 1, draw a semicircle with the turntable of the excavator 6 as the center, and take the arm length when the straight arm of the excavator 6 is straight and the arm length when the arm is curved respectively as the radius, The region between the above two semicircles forms a semicircular area to be excavated 2; 1. A car 5 is parked at the position of the operation section 3 on the right; then the excavator 6 loads the cars 5 parked at the positions of the operation section 7 on the left and the operation section 3 on the right according to the following steps:

[0016] ① First, excavate the right working section 3, and load the vehicle 5 parked on the right working section 3;

[0017] ② The car 5 located at the right side operation section 3 is fully loaded and drives away, the excava...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com