Test method and test device for chemical contraction of cement

A technology of chemical shrinkage and testing equipment, which is applied in the direction of measuring equipment, mechanical equipment, instruments, etc., can solve problems such as large testing errors, inability to hydrate cement, and missing volume changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1, the steps are as follows:

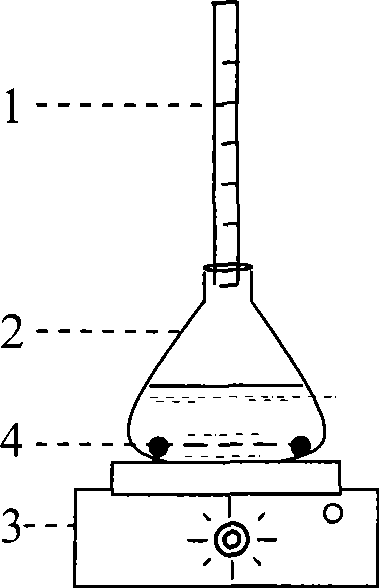

[0020] (1) Take 50g of cement and stainless steel beads 4 and put them into the pycnometer 2, add about 50g of water and shake the pycnometer so that the cement and the stainless steel beads 4 are stirred together to form a cement slurry.

[0021] (2) Spread a layer of butter on the outer edge of the measuring tube 1 along the frosted mouth, then insert the buttered end into the mouth of the specific gravity bottle, and then use a lit candle to seal the connection between the measuring tube 1 and the specific gravity bottle 2 with wax tight.

[0022] (3) Fill the pycnometer with water from the other end of the measuring tube 1 to the full scale of the measuring tube 1, and then drop a drop of liquid paraffin on the water surface in the measuring tube to prevent evaporation of water.

[0023] (4) Place the device in a constant temperature curing room at 20°C, turn on the magnetic stirrer 3 to make the stainless steel beads 4 dri...

Embodiment 2

[0025] Embodiment 2, the steps are as follows:

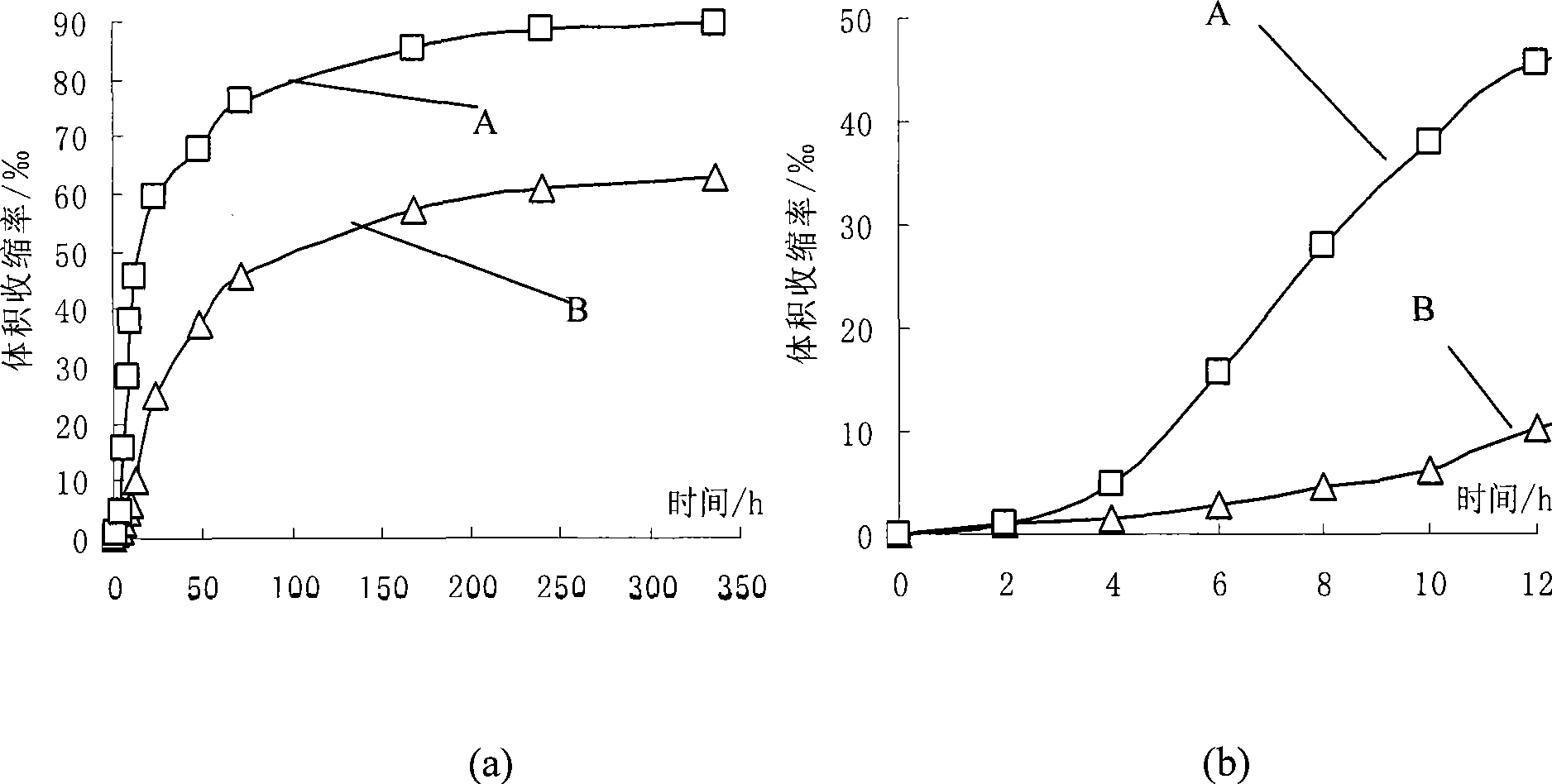

[0026] (1) according to the chemical shrinkage value of the operation test 50g cement of embodiment 1, test the volume of cement after finishing the test, the shrinkage amount tested in each period is converted into volume shrinkage rate, take time as the axis of abscissa, take chemical shrinkage rate As the ordinate axis, draw the curve of time and corresponding chemical shrinkage rate, denoted as A.

[0027] (2) Use the traditional method to do the chemical shrinkage test of the same cement, that is, put 50g of cement into the pycnometer, add about 50g of water and stir evenly, connect the pycnometer with a buttered measuring tube and seal it tightly with wax, and then fill it with water until The measuring tube is full scale, and finally drop a drop of liquid paraffin on the liquid surface and start timing. The operation between adding water and starting timing is also controlled within 10 minutes. After the test is done, me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com