Image forming apparatus

A technology of image and toner image, applied in the field of image forming device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

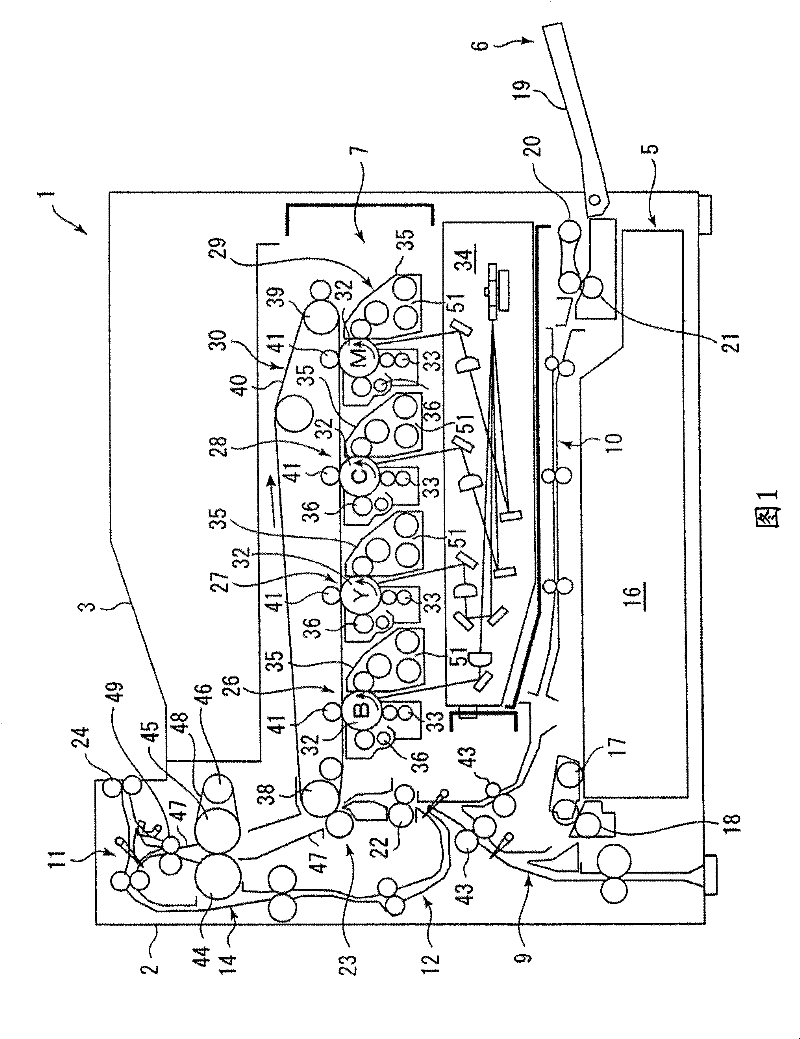

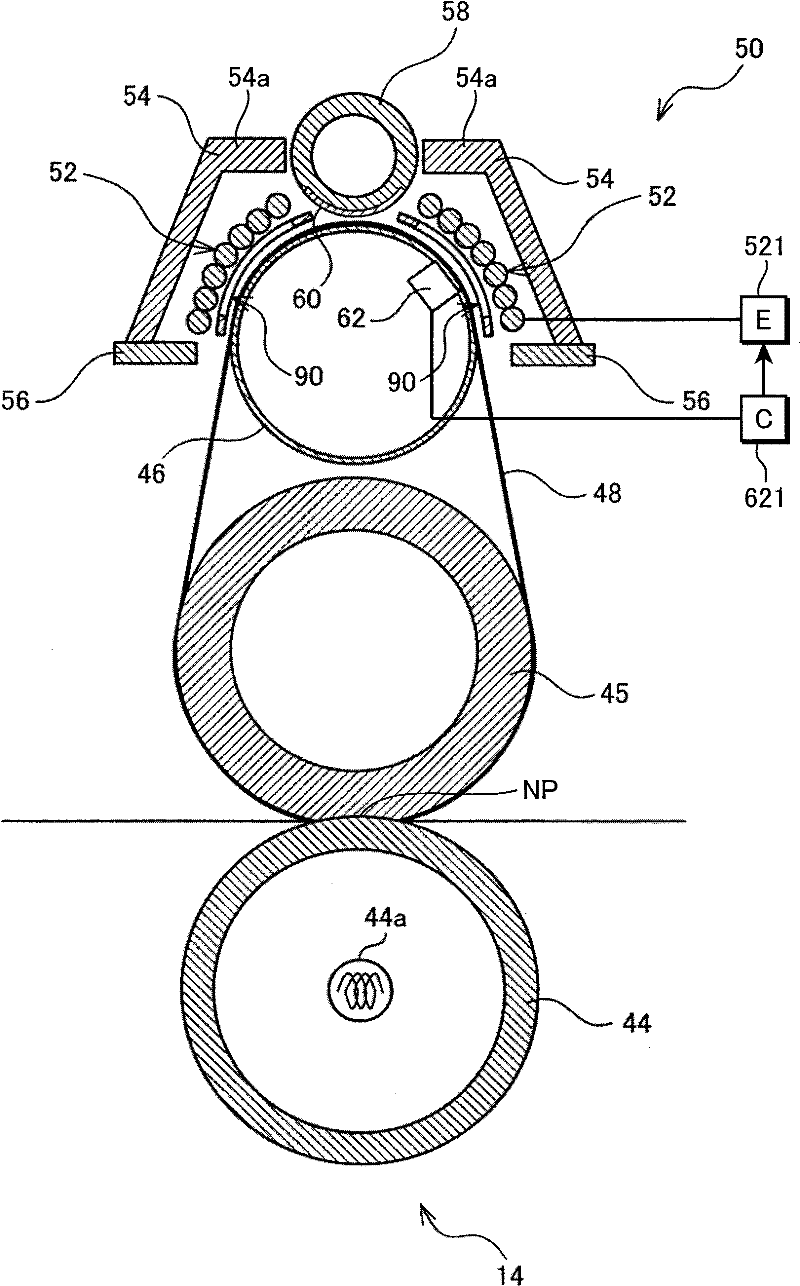

[0079] figure 2 It is a longitudinal sectional view showing the structure of the fixing unit 14 of the first embodiment. exist figure 2 , shows a state where the fixing unit 14 mounted on the image forming apparatus 1 is rotated about 90° in the counterclockwise direction. Thus, in figure 1 The feeding direction from bottom to top in figure 2 from right to left. In addition, in the case where the device main body 2 is larger (such as a digital composite machine), it may be installed as figure 2 orientation shown.

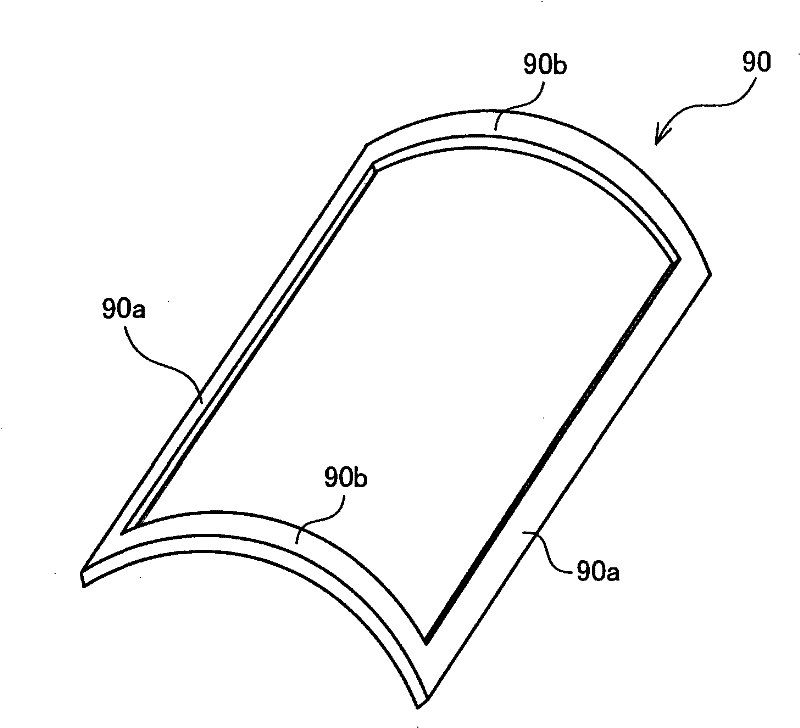

[0080] The fixing unit 14 has the pressure roller 44 , the fixing roller 45 , the heating roller 46 , and the heating belt 48 as described above. As described above, since the pressure roller 44 is a metal roller and the surface layer of the fixing roller 45 has an elastic layer of silicon sponge, a flat nip NP is formed between the pressure roller 44 and the fixing roller 45 . In addition, a halogen heater 44 a is provided inside the pressure roller 44 . T...

no. 2 approach

[0159] Next, details of the fixing unit 14 of the second embodiment will be described. Figure 16 It is a longitudinal sectional view showing the fixing unit 14 of the second embodiment. exist figure 2 Middle indicates a state where the fixing unit 14 actually mounted on the image forming apparatus 1 is rotated about 90° in the counterclockwise direction. Thus, in figure 1 In the direction of paper transport from bottom to top, in Figure 16 Middle is from right to left. In addition, in the case where the device main body 2 is larger (such as a digital composite machine), it may be Figure 16 Install in the orientation shown.

[0160] The fixing unit 14 includes a pressure roller 44, a fixing roller 45, and a heating belt 148 wound around its outer circumference. The pressure roller 44 is a metal roller, and the surface layer of the fixing roller 45 (inside the heating belt 148 ) has an elastic layer of silicon sponge, so a flat nip NP is formed between the pressure rol...

no. 3 approach

[0209] Figure 24A and Figure 24B It is a longitudinal sectional view showing a third embodiment of the fixing unit 14 . The third embodiment differs from the first and second embodiments in that the fixing unit 14 has an enclosed type IH coil unit 50 . In addition, the configuration of the magnetic adjustment member 160 may be the same as that of the second embodiment. Additionally, using the reference Figure 17 The magnetic adjustment unit described above can switch the magnetic adjustment member 160 between the shielding position and the withdrawn position.

[0210] That is, the fixing unit 14 of the third embodiment includes the pressure roller 44 and the heating roller 46 , and fixes the toner image while conveying the paper between their nips. In addition, since the heating roller 46 is a metal roller, this structure is suitable for fixing a monochrome image. However, it is also possible to form a flat nip NP between the heating roller 46 and the pressure roller 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com