Horizontal preparation method of sanitary napkin with protective wings and device thereof

A preparation device and technology for sanitary napkins, applied in the field of sanitary napkins, can solve the problems of waste of basic materials and energy, waste of raw materials and energy, etc., and achieve the effects of high production efficiency, cost saving, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

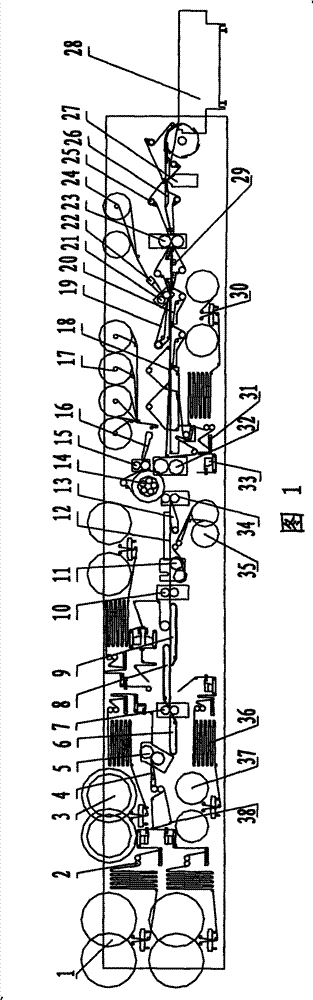

[0030] A method for preparing a sanitary napkin with laterally extended wings, comprising the process of preparing an absorbent body, compounding a base film, cutting, and wrapping in small packets; the manufacturing process of the sanitary napkin with laterally extended wings is completed continuously, and the preparation of the absorbent body, compounding the base film, Laminate the skin care layer and the backing paper, and then cut it. The whole process adopts horizontal side-by-side molds to carry out product horizontal forming production.

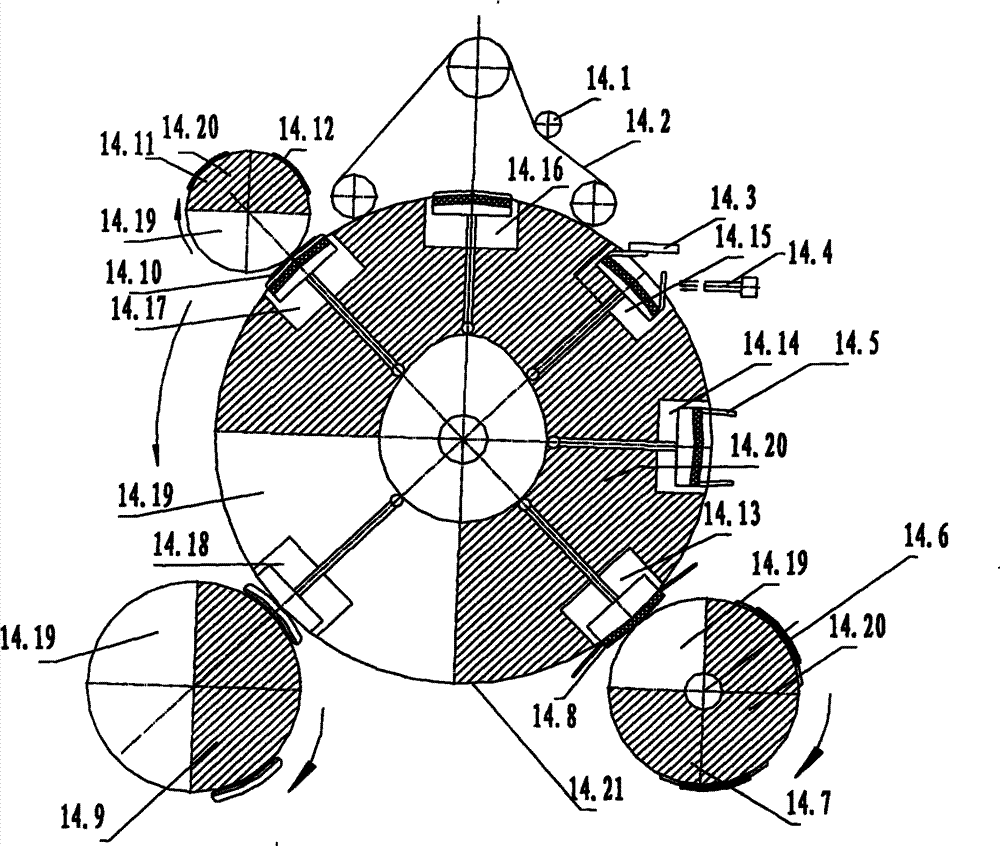

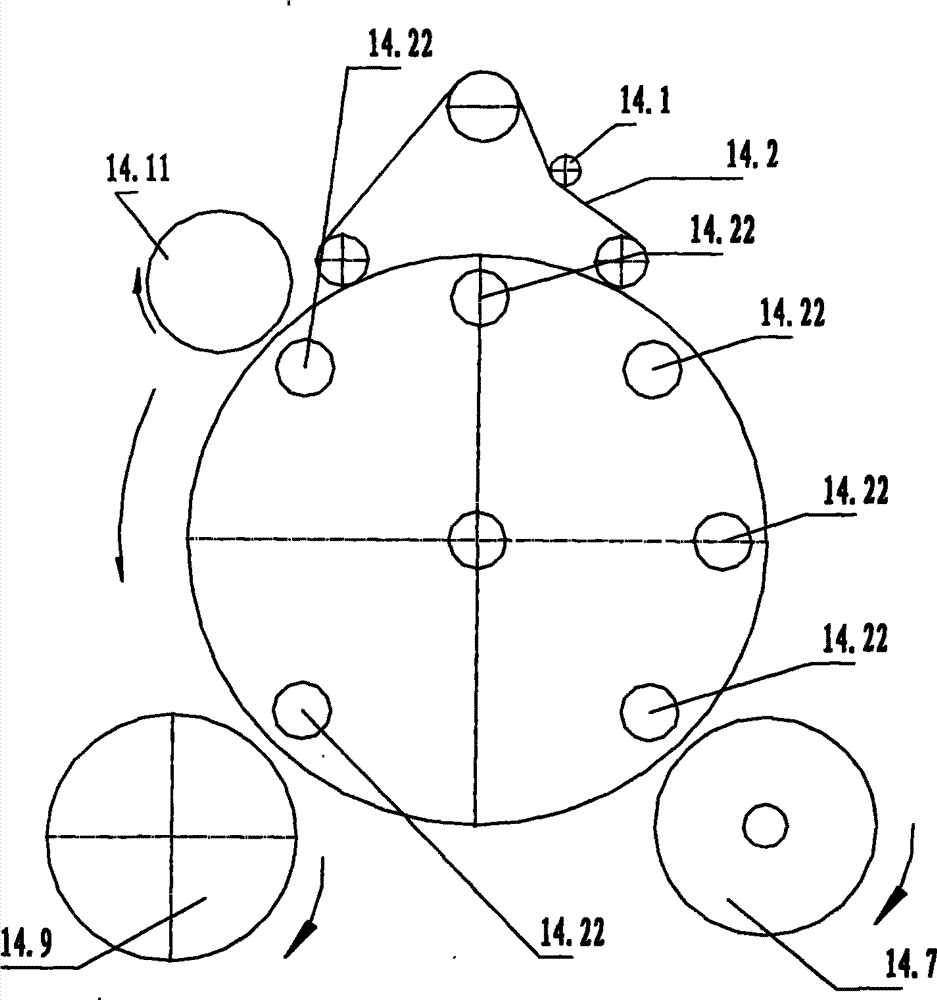

[0031] The preparation method of the sanitary napkin with side wings is completed in this way: the absorber is combined with the suction box 4 of the skin care layer through the upper and lower material shafts, and the absorber is cut off by the absorber knife holder 5, and the base film and the surface layer are sucked before sealing. The bellows are compounded at 6 places, and the product diversion structure is realized through the ...

Embodiment 2

[0033] The device for preparing sanitary napkins with horizontal wings includes an absorber preparation mechanism, a base film composite mechanism, a cutting mechanism, and a packet covering mechanism; there are suction boxes for the skin care layer 4, knife holders for the absorbent body 5, suction boxes 6 before sealing, and diversion Groove knife holder 7, Zhoufeng knife holder 10, backing paper knife holder 11, adapter suction hub 14, folded wing knife holder 15, wing paper suction box 16, belt triple folding 18, compacting device 19, supporting device 20, Rubber strip knife holder 21, end seal cutter holder 23, rubber strip rack material shaft 24, flat belt tensioner 25, waste reject device 26, waste box 27, small bag 28, pallet device 29, automatic material receiving device 30, swing table Floating roller 31, packaging composite knife holder 32, deviation corrector 33, cutting knife holder 34 and other parts; among them, absorber knife holder 5, diversion groove knife hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com