Biomass burning fluidized bed boiler

A material flow, boiler technology, applied in the direction of fluidized bed combustion equipment, combustion method, combustion type, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

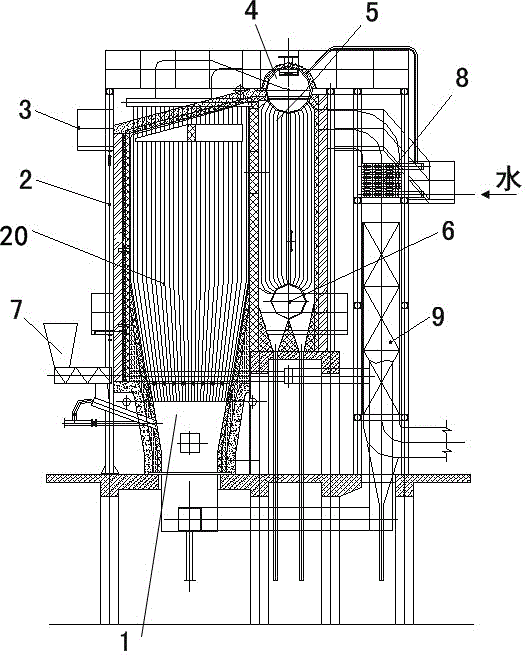

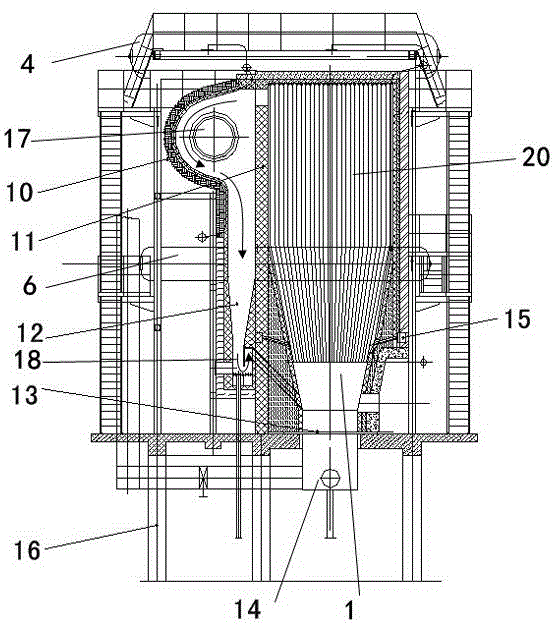

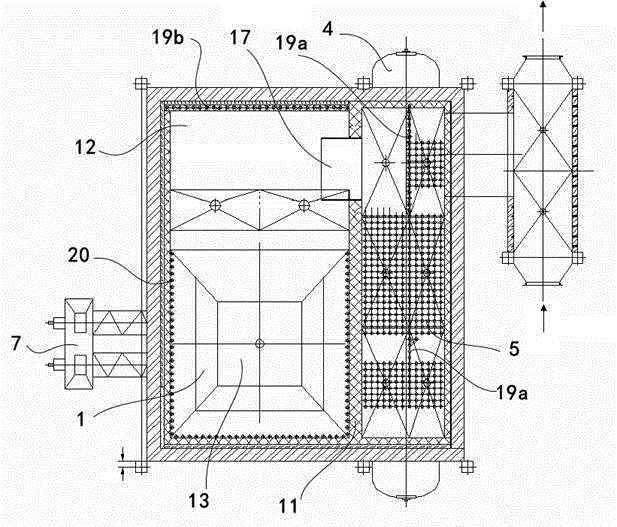

[0023] refer to Figure 1 to Figure 3 , the present invention includes a furnace wall, a primary air duct 14, and a secondary air duct 15. The furnace wall is a heavy or semi-light furnace wall, including a furnace 1, and a separation chamber 12 is arranged on one side of the furnace 1, and the entrance of the separation chamber 12 is It is connected to the channel at the outlet of the furnace 1, and the entrance of the separation chamber 12 has an arc-shaped cover 10, and the centerline direction of the arc-shaped cover 10 is provided with a flue gas outlet 17, and the discharge port of the separation chamber 12 is connected to the inlet of the furnace 1. A feeder 18 is provided at the connection; a water-cooled pipe 20 is provided around the furnace 1 . The separation chamber 12 can also be called a cyclone separation chamber. This technical solution focuses on solving the problem that due to the uneven particle size and large humidity difference of the biomass material, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com