Paper web stabilizer of high-speed paper machine

A high-speed paper machine and stabilizer technology, which is applied in the paper machine, paper making, dryer section, etc., can solve the problems of paper wrinkle, slow paper machine speed, and paper sheets that cannot be attached to the dry blanket.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

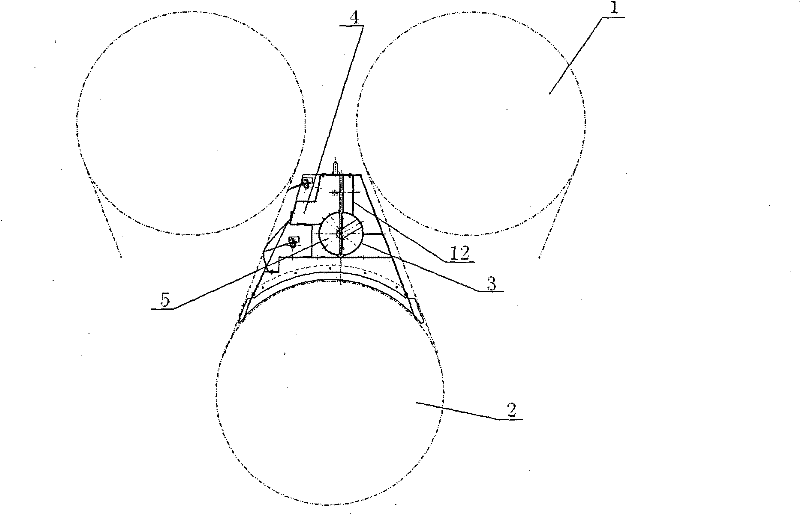

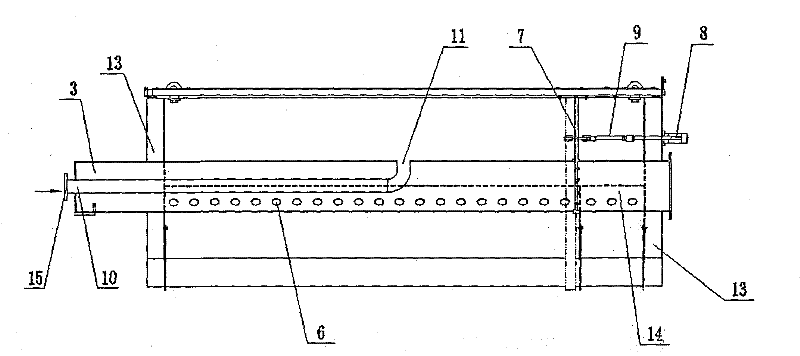

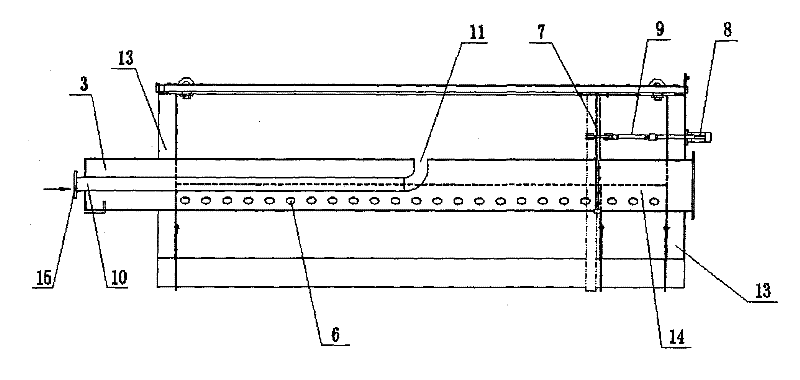

[0010] Referring to the attached picture:

[0011] Between the drying cylinder 1 and the vacuum roll 2, a large air duct 3 parallel to the axis of the drying cylinder is provided. The large air duct is divided into a blowing area 4 and a suction area 5. There are three rows of air suction holes 6 with a diameter of 10-80mm and a hole distance of 40-60mm evenly distributed on the lower end and two sides, and an automatic control valve is installed in the paper threading area at one end of the large air duct, which accounts for about 3 / 3 of the pipe length. 7; The automatic control valve is controlled by the air cylinder 8 and the air rod 9 .

[0012] Described blowing area is to be provided with the blowing pipe 10 that is connected with blower fan at the center of large air pipe, the inlet 15 of the blowing pipe that is connected with blower fan is located at one end of large air pipe, welds and assembles partition with steel plate on the periphery of large air pipe. Plate 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com