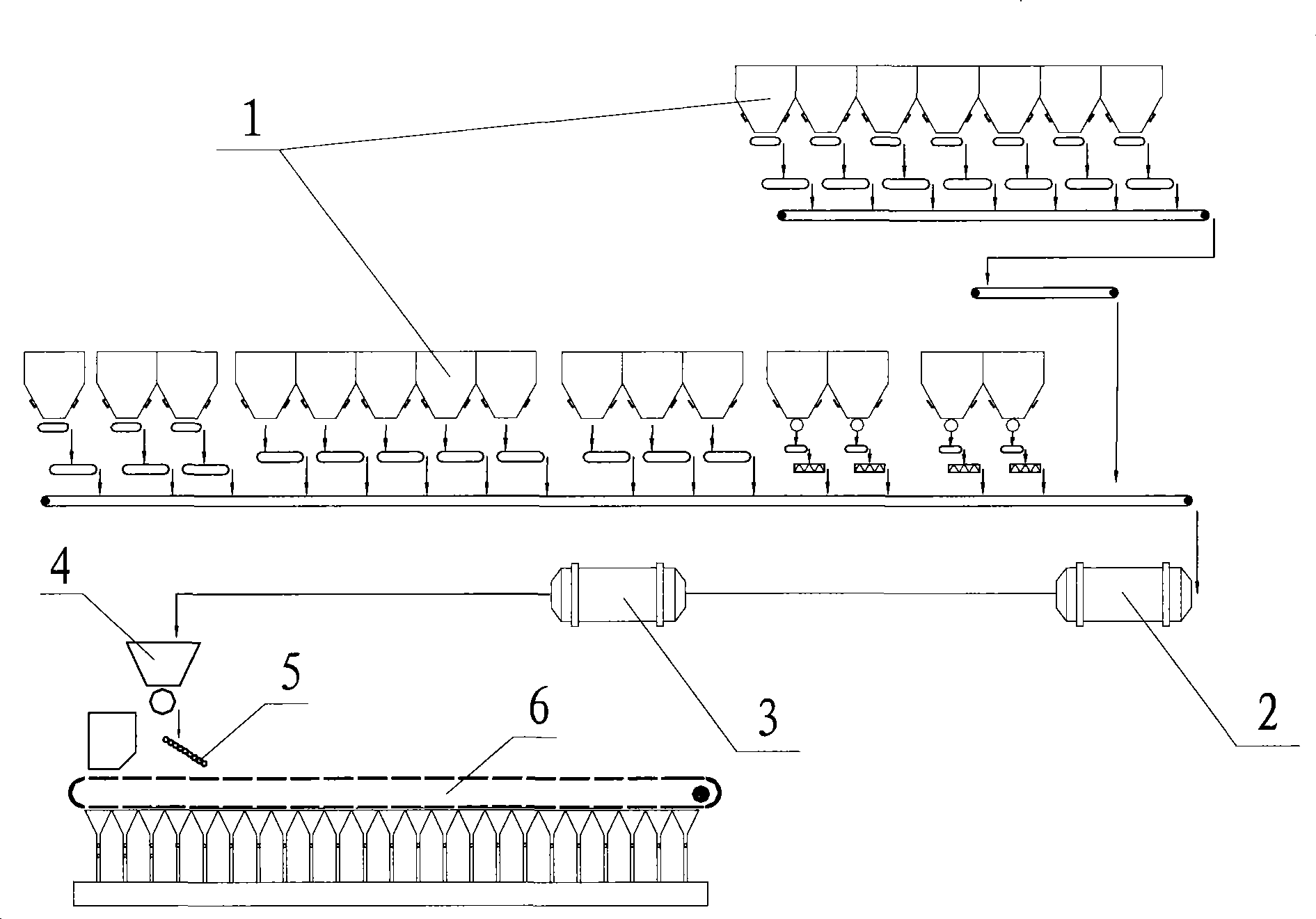

Material flow control apparatus and method for sintered batching ore storage bin

A silo and material flow technology, applied in the field of control, can solve problems such as affecting sintering production and reducing sintering productivity, and achieve the effects of improving sintering productivity and avoiding aggravation of material blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

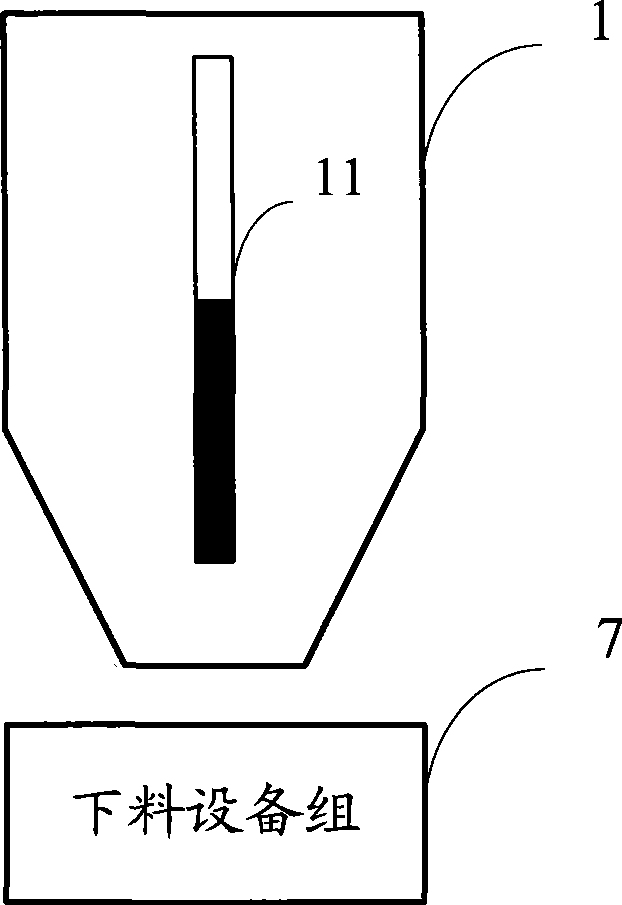

Image

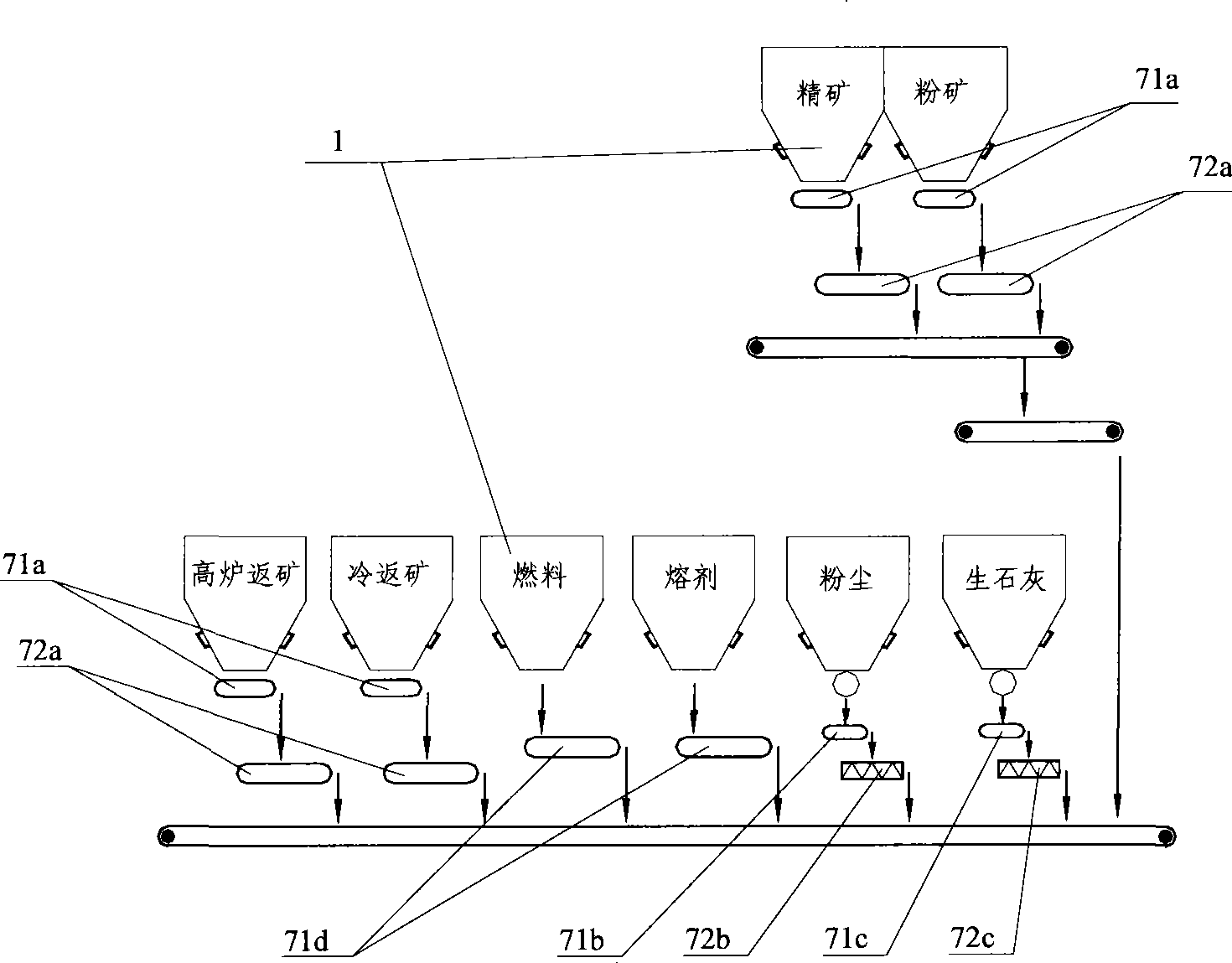

Examples

Embodiment 2

[0067] The difference between the device in the second embodiment and the first embodiment is that the control device 8 further includes a vibrator 86 arranged on the side wall of the mine bin 7 .

[0068] refer to Figure 6a with Figure 6b , are schematic diagrams of the installation positions of two vibrators and four vibrators, respectively.

[0069] On the frustum-shaped side wall of the bottom of the mine bin 1, 2 or 4 or more vibrators 86 are evenly arranged.

[0070] The vibrator 86 is connected with the blockage judging unit 83 , receives the blockage signal sent by the blockage judging unit 83 , starts to work, and beats the side wall of the mine bin 1 to eliminate the blockage in the mine bin 1 .

[0071] In order to remove the blockage in the mine bin 1 by beating the side wall of the mine bin 1 with the vibrator 86, the side wall at the bottom of the mine bin 1 must be made of steel plate.

[0072] In actual production, the long-time work of the vibrator 86 wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com