Worktable for measuring tire mold roundness and curvature

A workbench and roundness technology, applied to measuring devices, instruments, optical devices, etc., can solve problems such as impractical, expensive, inconvenient and simple measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

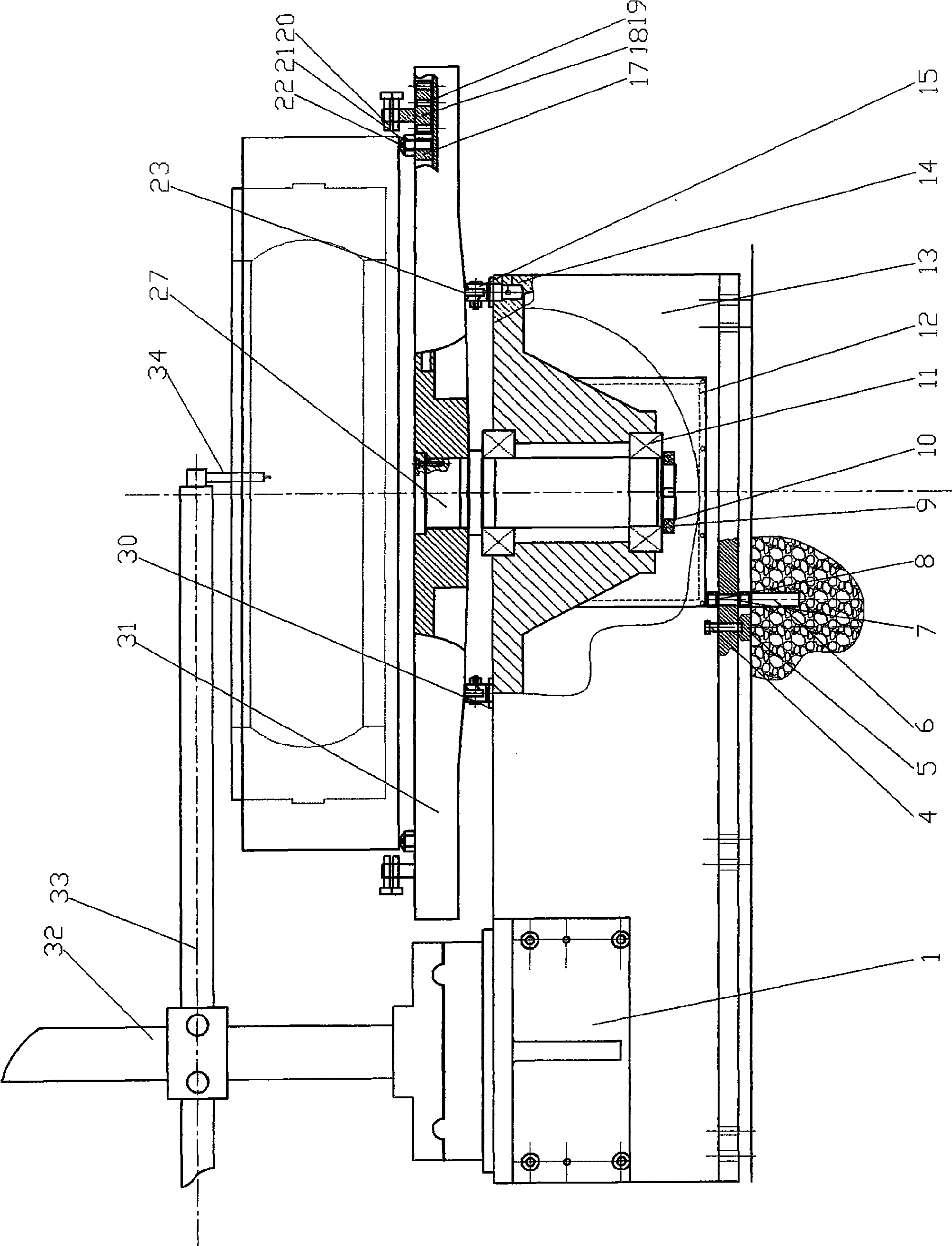

[0005] The workbench for measuring the roundness and curvature of the tire mold includes a machine base 13, one side of the machine base 13 is provided with a turntable 31, the other side of the machine base 13 is provided with a machine base widening angle iron 1, and the machine base widening angle iron 1 is A support column is provided, and an infrared roundness measuring instrument 32 is provided on the support column. The turntable 31 is provided with a roundness correction mechanism and a plane correction mechanism. The turntable 31 is also provided with a main shaft 27, and the turntable 31 is movably connected with the machine base 13 through the main shaft 27. . The roundness correction mechanism includes a roundness correction support 18 on which a hexagon socket head screw 20 is arranged, and a hexagon socket head set screw 19 is arranged between the correction circle support 18 and the rotating disk 31 . The plane correction mechanism is that the turntable 31 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com