Method for measuring volume change of volume-changeable chamber bellows of constant pressure type gas flow meter

A technology of gas flowmeter and volume change, which is applied in the direction of volume measurement instrument/method, liquid/fluid solid measurement, container/cavity capacity measurement, etc., to achieve the effect of facilitating maintenance and maintenance, improving measurement accuracy, and avoiding disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

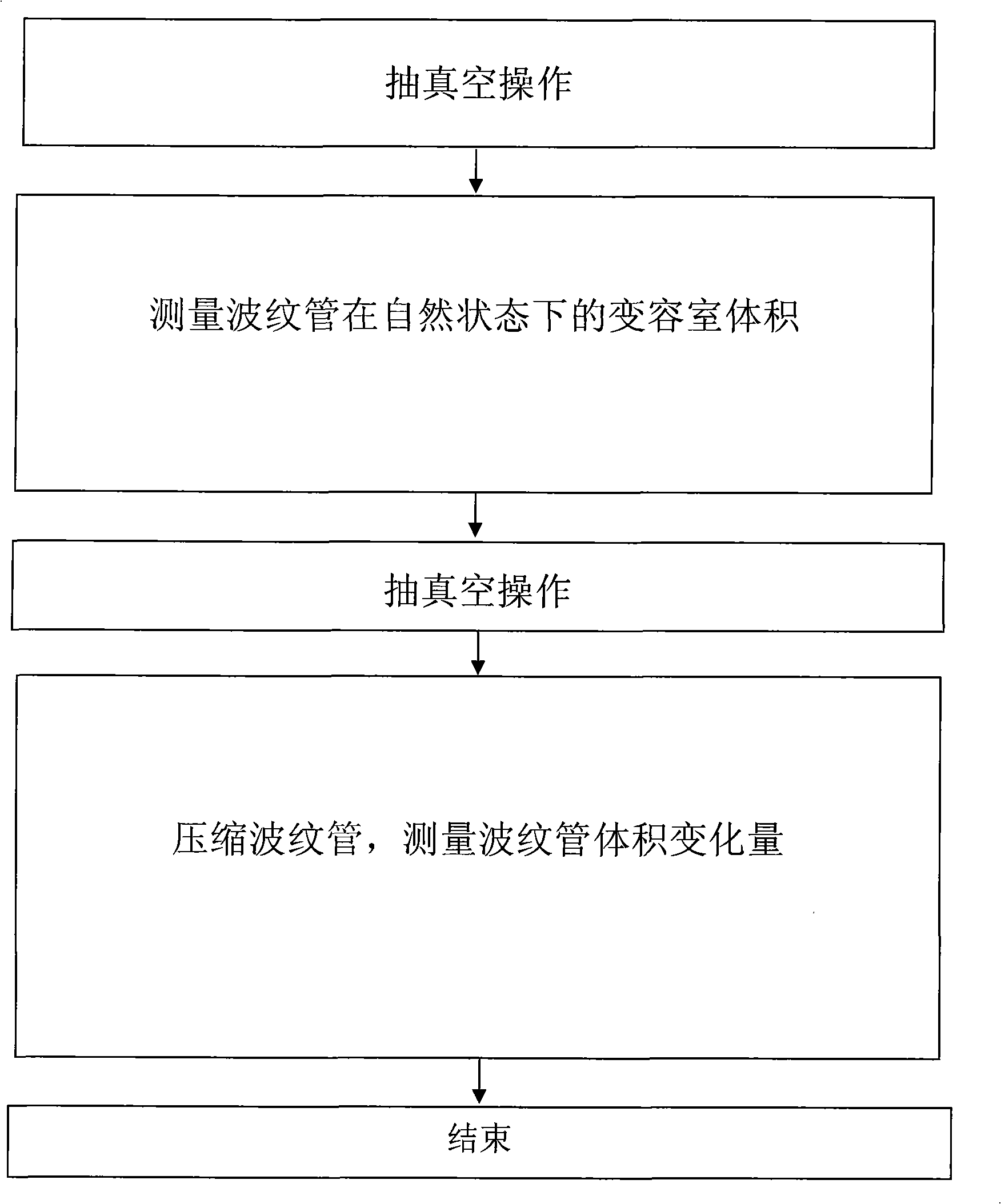

Method used

Image

Examples

Embodiment

[0025] Step 3: The air -bearing room and reference room pipeline through the gas drawing system are vacuum, and the vacuum is 0.01Pa;

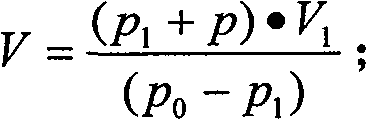

[0026] Step 4. In the natural state of the ripple tube, the pressure value of the transformation room (volume V value of 1.178L) and the reference room pipeline through the gas supply system is P 2 N 2 , Measured by the stress pressure meter P 2 = 153.04Pa; then the pressure of the balancing room, recorded from different pressure pressure meters to the pressure value P 3 = -0.05Pa.After that, the wavelet tube compressed through the flat movement mechanism, and the compression volume was 8mm, which generated the volume change of the ripple tube. After the balancing pressure, the pressure value of the pressure meter from the differential pressure meter to the pressure value p 4 = 20.30Pa, then the volume of the volume room changes ΔV = ( p 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com