Tripod constant velocity universal joint

A constant velocity universal joint and tripod-type technology, which is applied in elastic couplings, mechanical equipment, couplings, etc., can solve problems such as increased costs, and achieve the effects of increased life and reduced surface pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

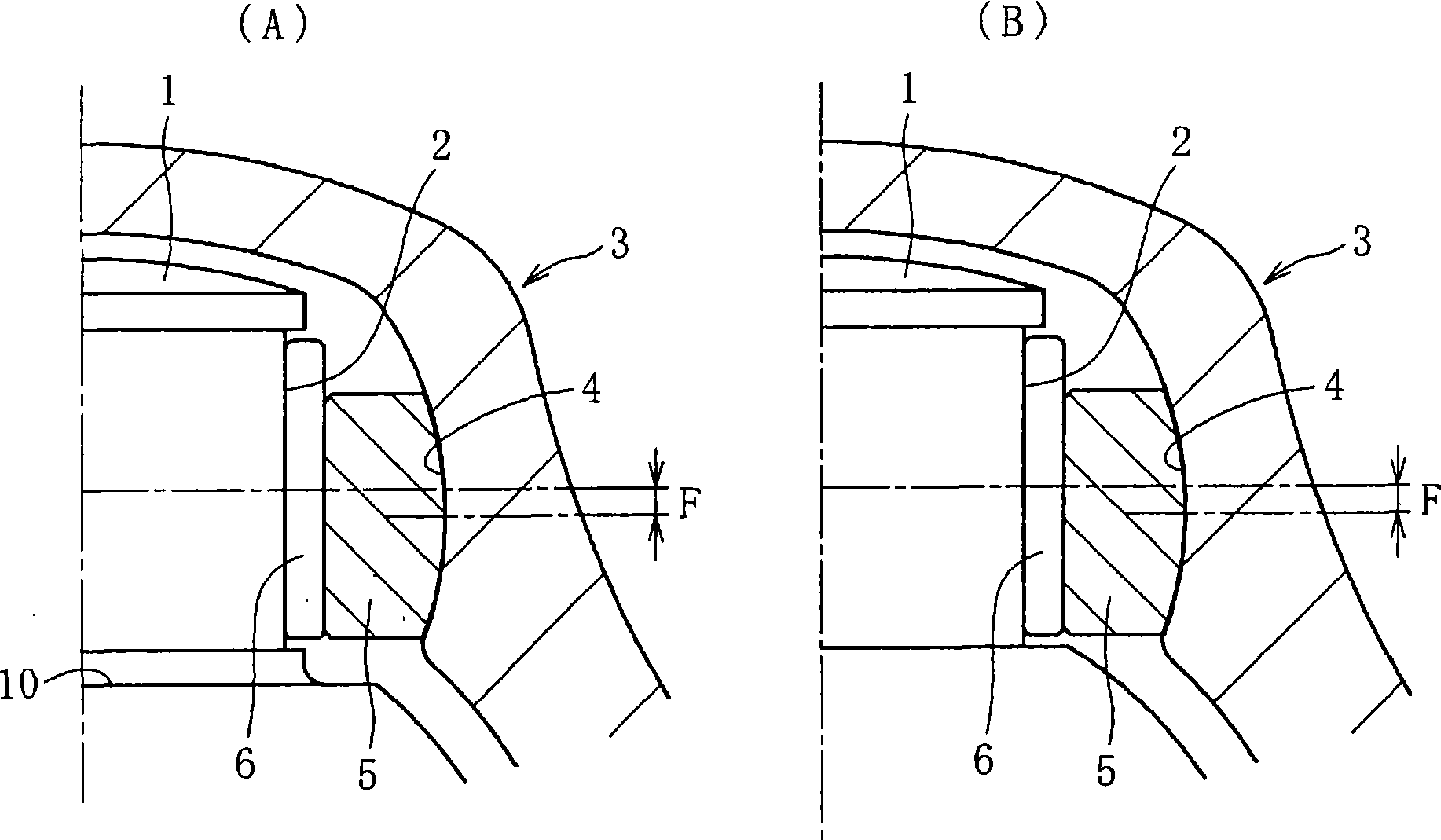

[0048] Below, according to Figure 1 to Figure 10 Embodiments of the present invention will be described.

[0049] The basic form of the constant velocity universal joint of the present invention and Figure 11A The same as the conventional tripod type constant velocity universal joint. The parts that are different from the conventional ones are the shape of the peripheral surface of the pin shaft and the shape of the inner diameter of the opening of the outer joint member. Thus, parts different from conventional ones will be described based on the following drawings.

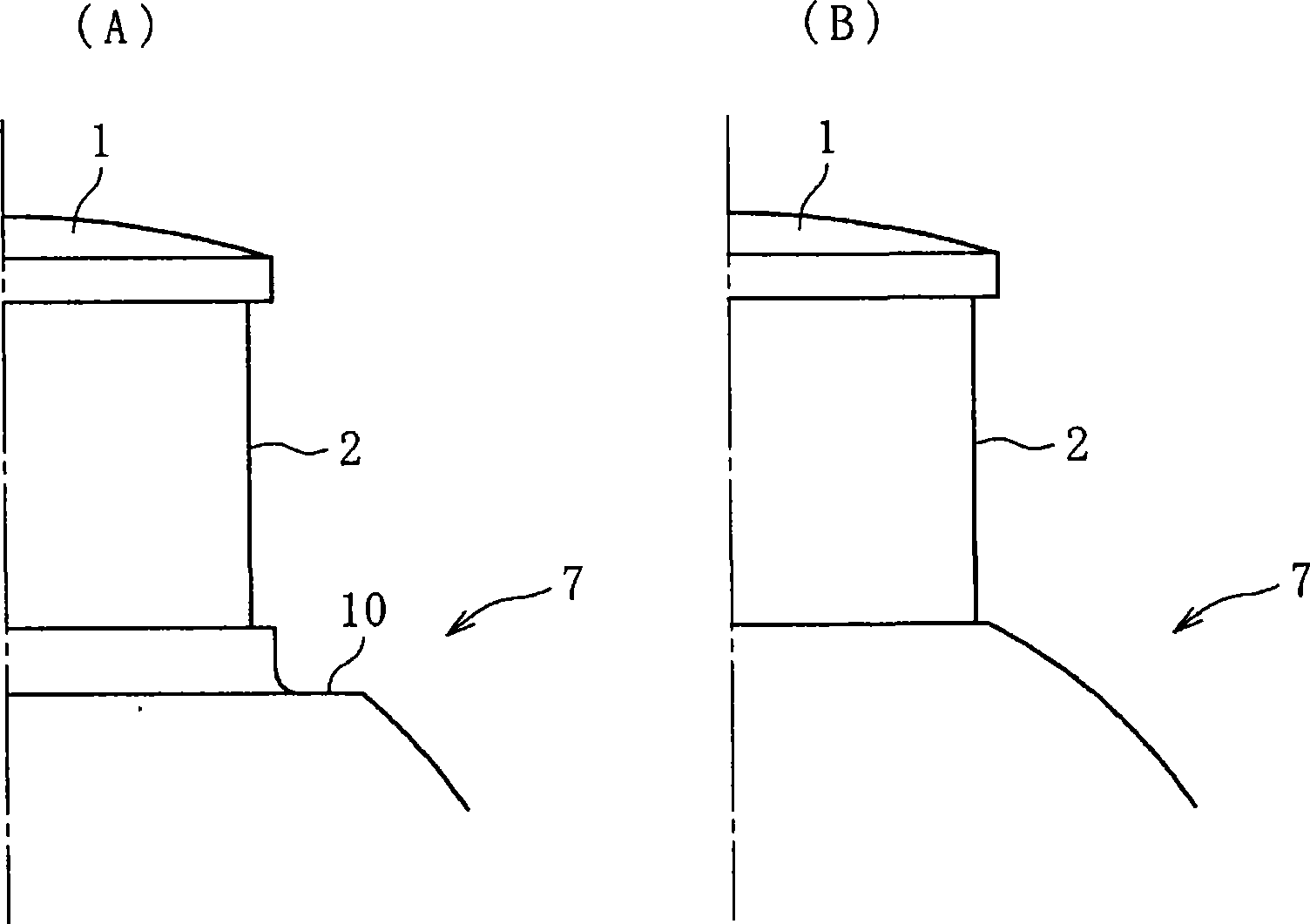

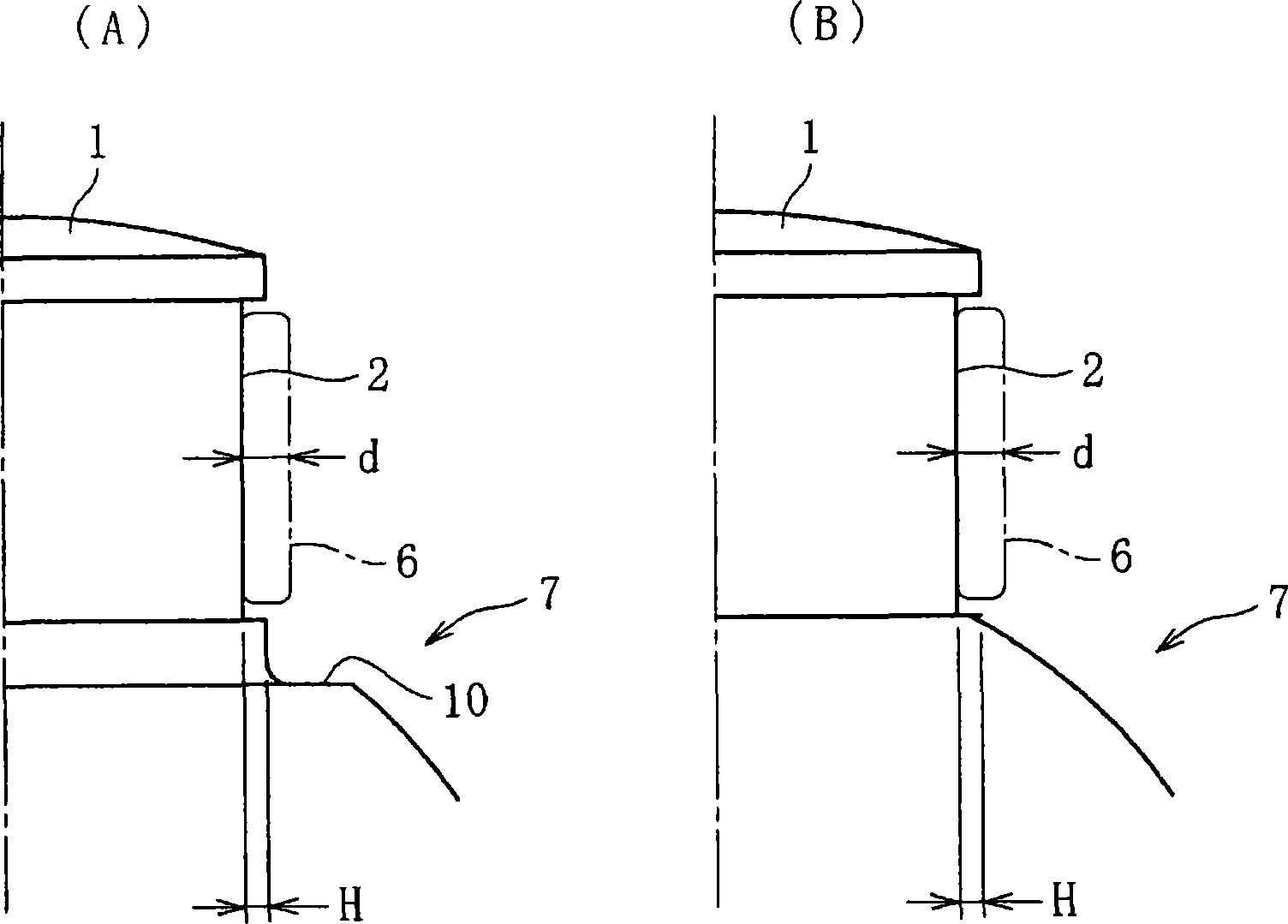

[0050] Such as figure 1 As shown in (A) and (B), in the first embodiment of the present invention, grooves 2 are formed on the outer peripheral surface of the foot shaft 1 in the circumferential direction. figure 1 The difference between (A) and (B) is the presence or absence of the root edge side step portion 10 of the foot shaft 1 . The groove portion 2 accommodates a plurality of needle rollers 6 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com