Submarine cutting system of resin micro beads

An underwater pelletizing and beading technology, applied in the direction of coating, etc., can solve the problems that the production of tiny beads cannot be realized, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

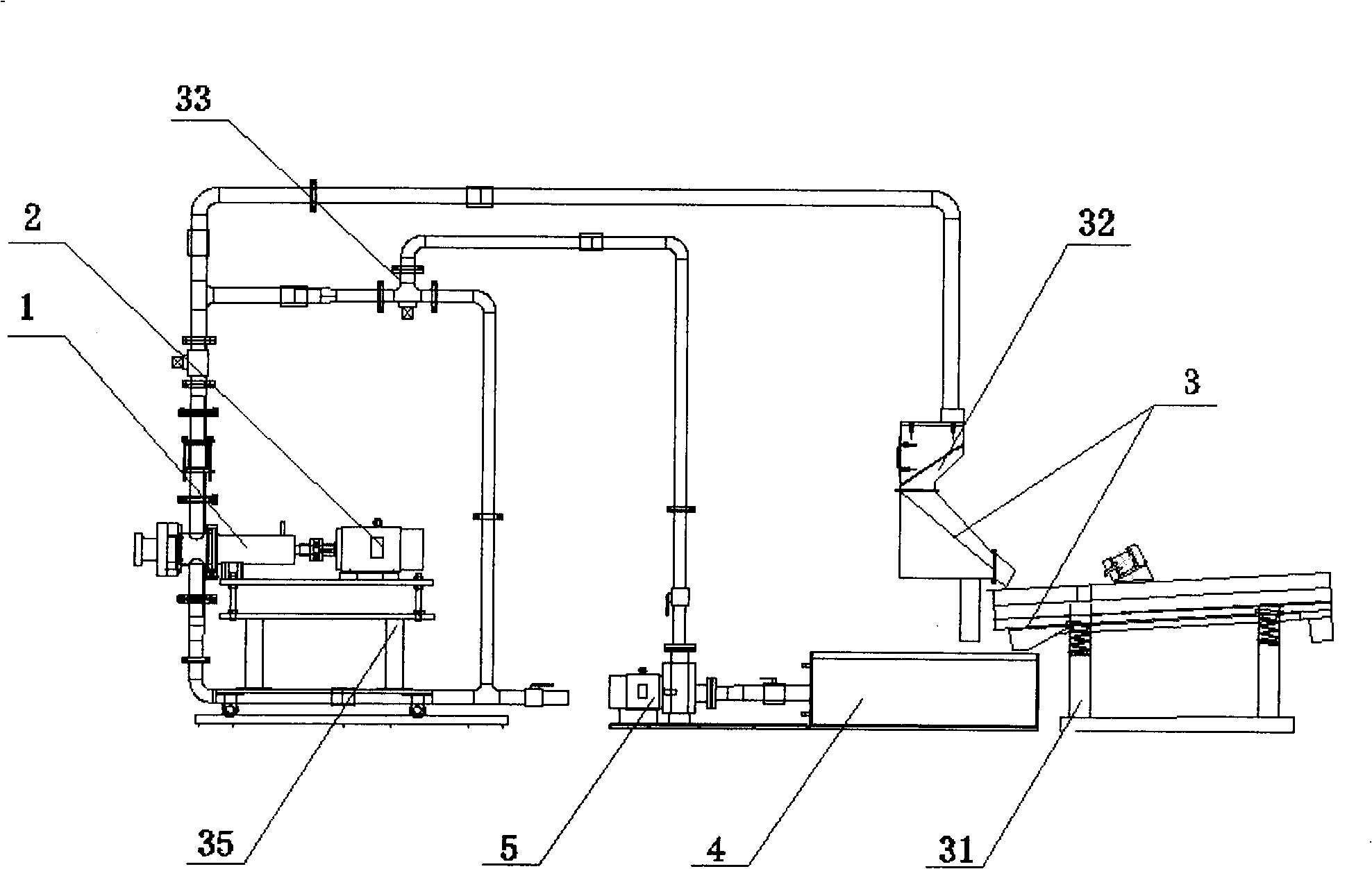

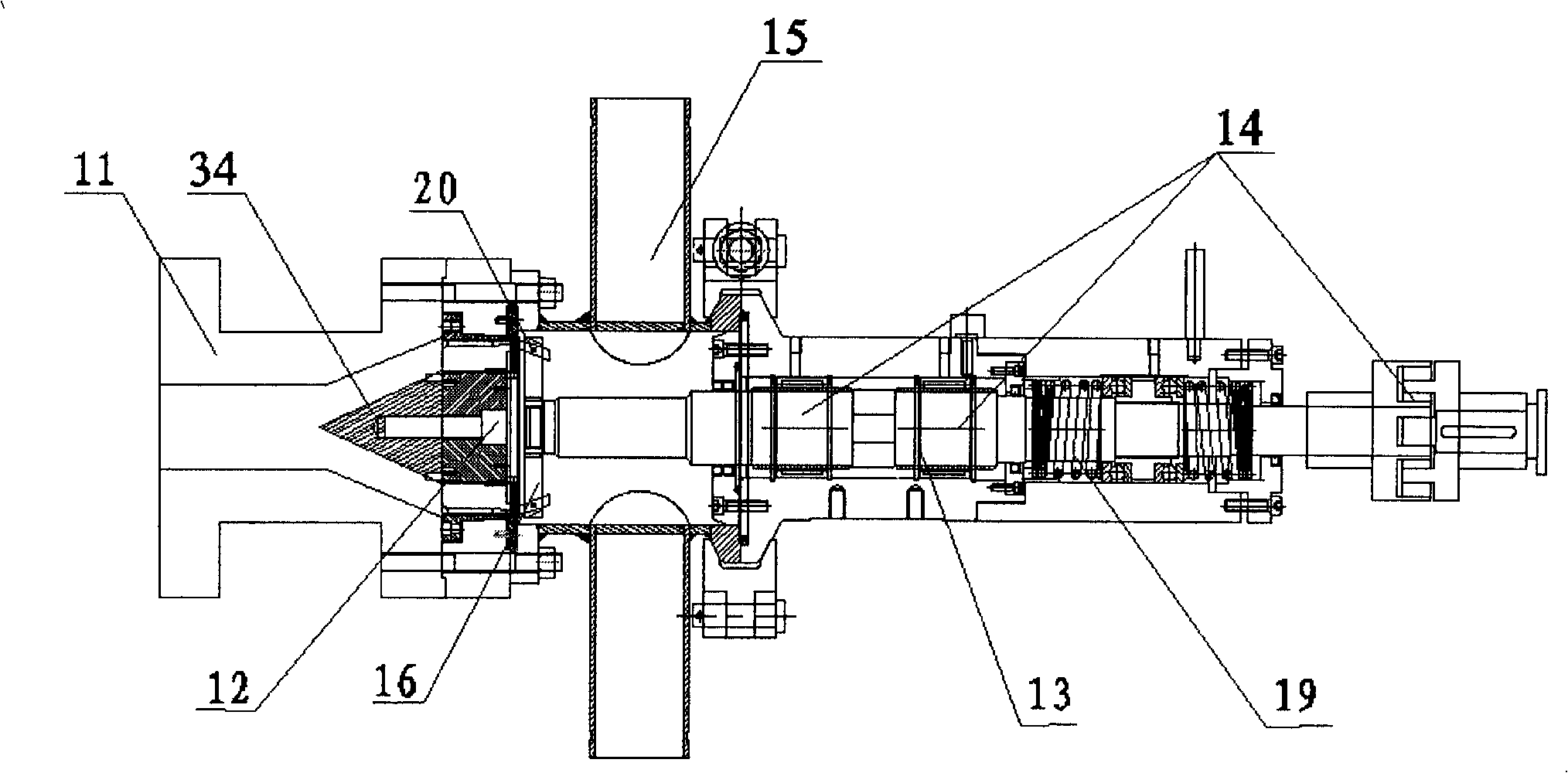

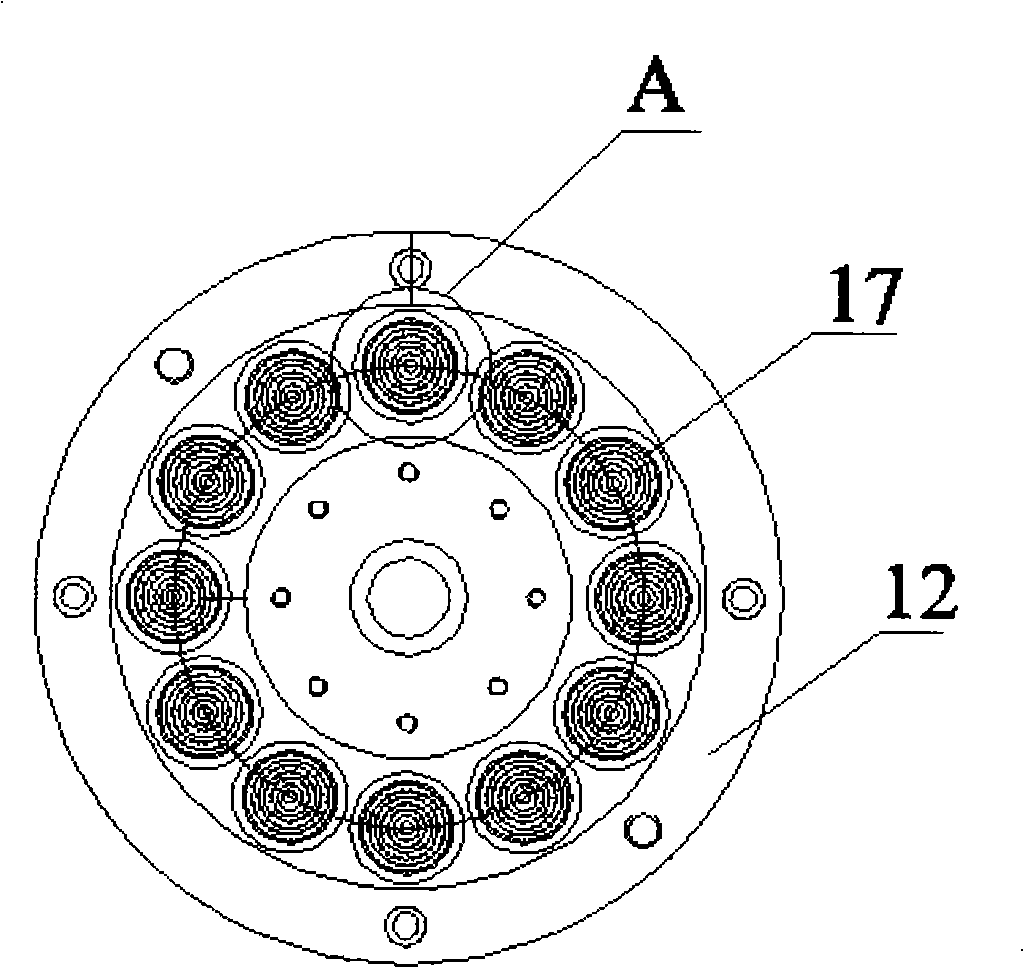

[0014] An underwater pelletizing system for resin micro-beads of the present invention includes an underwater pelletizing mechanism and a dehydration mechanism, the underwater pelletizing mechanism is connected to the dehydration mechanism through a water pipeline, and the electrical control cabinet is connected to the underwater pelletizing mechanism and the dehydration mechanism respectively , the underwater pelletizing mechanism includes an underwater pelletizer 1 and a motor 2, characterized in that: the pelletizer 1 includes a machine head 11, a template 12, a knife rest 13, a knife rest transmission device 14, and a trolley 35 with a track support and the water flow pipeline 15, there is a resin melt flow channel in the machine head, the template 12 is fixed on one side of the machine head 11, and the cutter head 16 is fixedly arranged on the knife rest 13, and the cutter head is close to the extrusion of the template 12 On the surface, the cutter head 16 is provided with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap