Slack eliminating device

A slack elimination device and slack elimination technology, applied in the directions of transportation and packaging, textile and papermaking, and conveying filamentous materials, etc., can solve the problem of broken parts, affecting the production efficiency of the package, shortening the life of the parts, etc. problem, to achieve the effect of improving lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

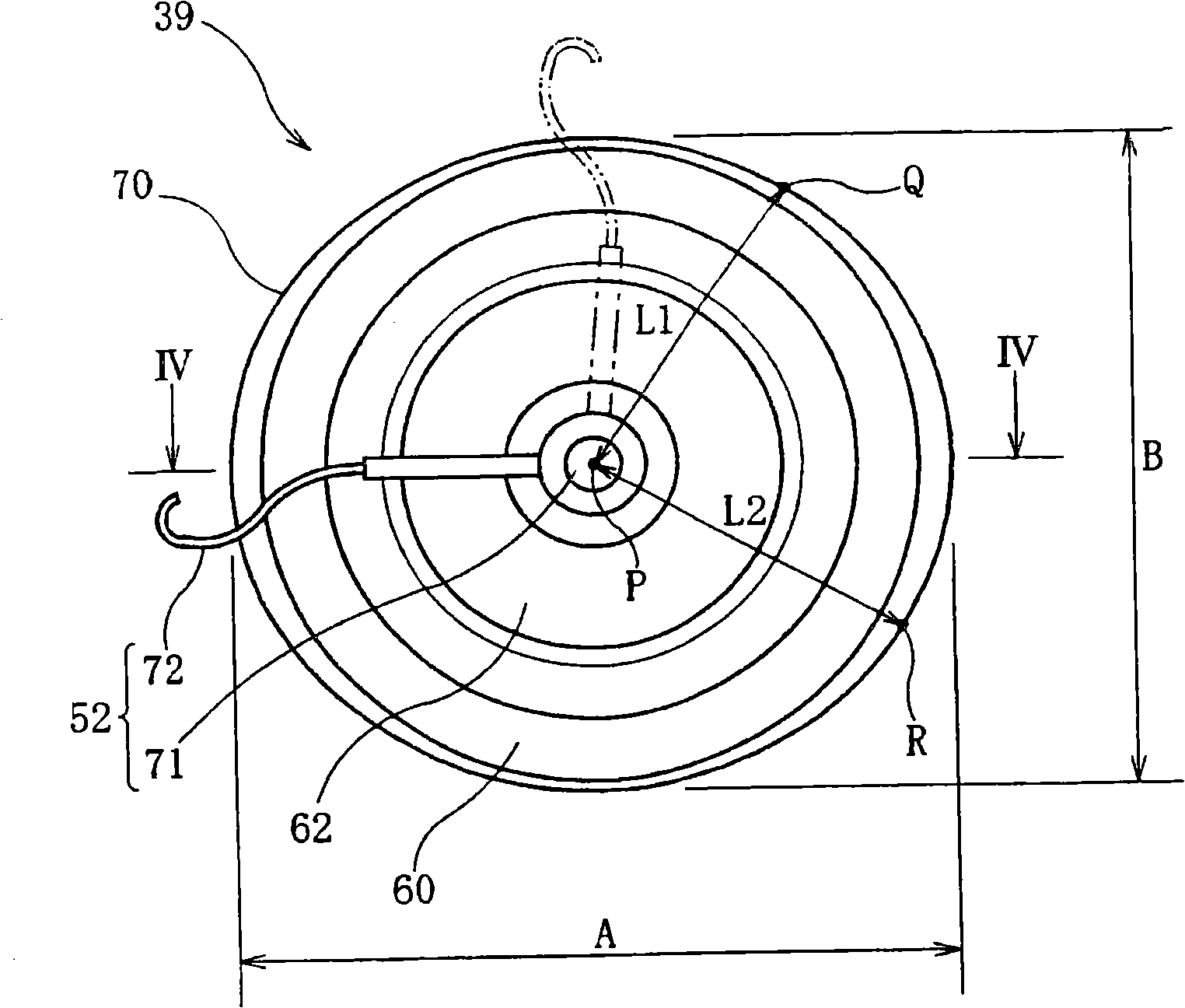

[0031] Embodiments of the present invention will be described below with reference to the drawings.

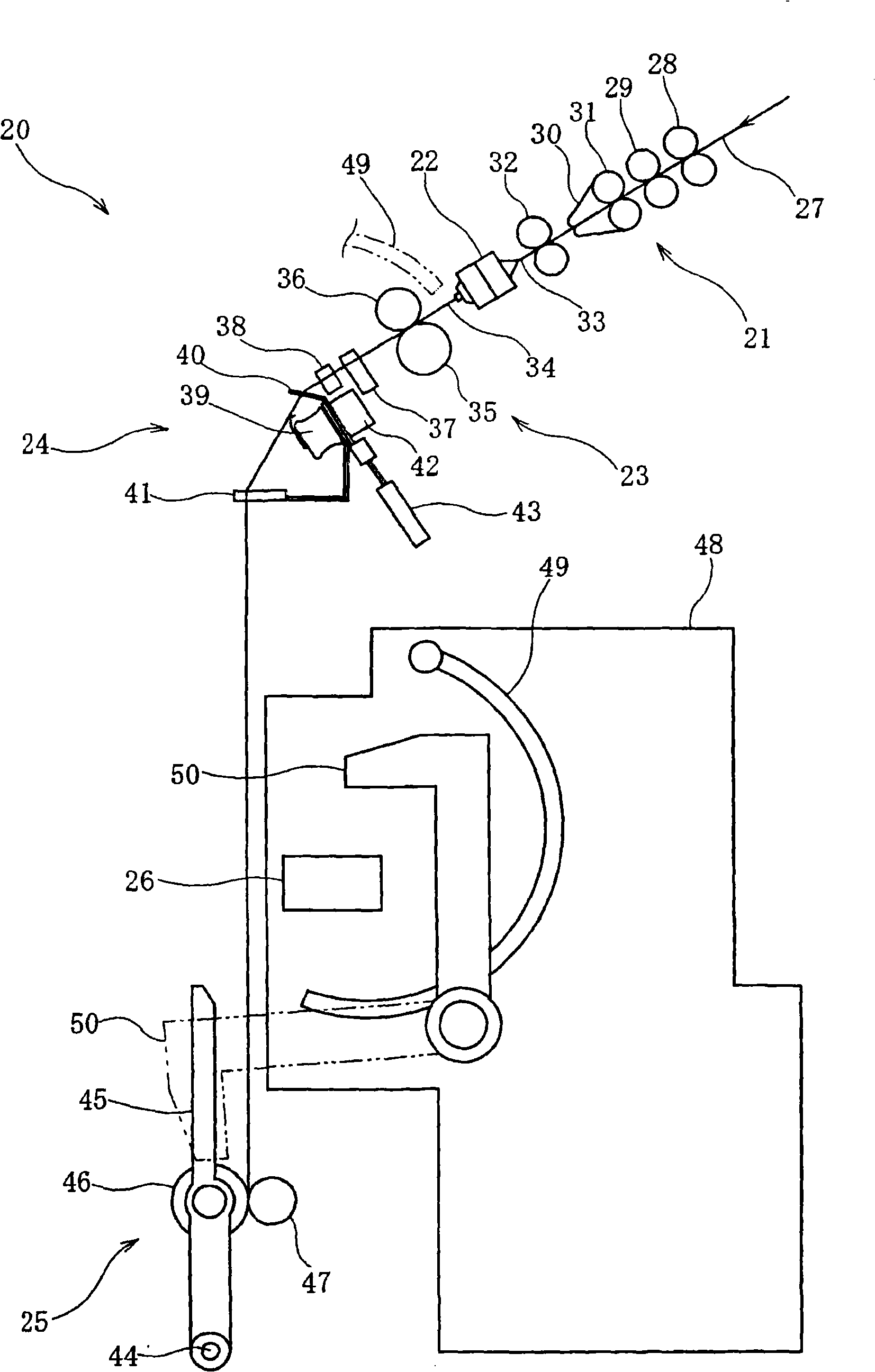

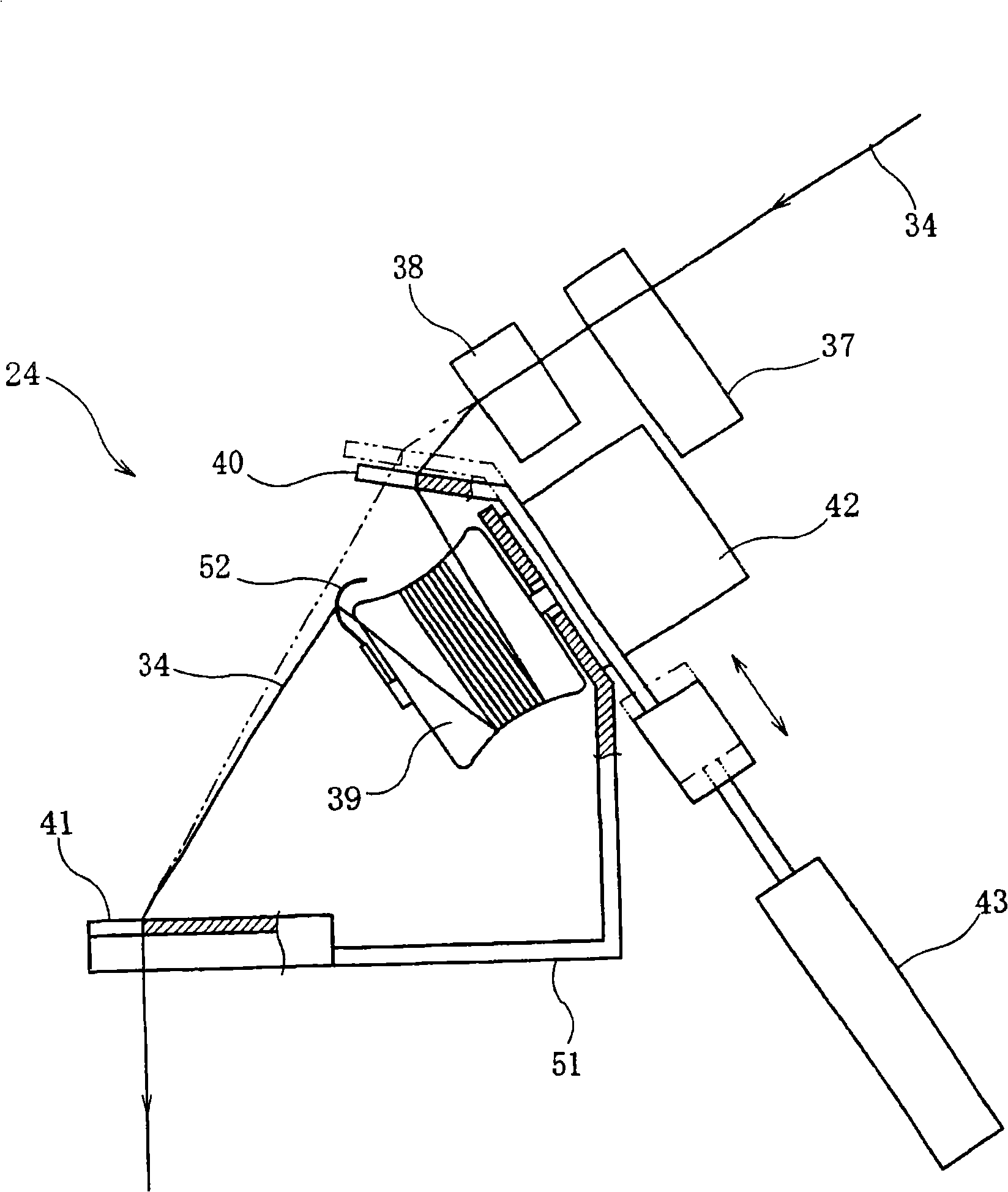

[0032] figure 1 It is a side view showing a schematic configuration of a spinning machine including the yarn slack eliminating device according to the first embodiment of the present invention.

[0033] refer to figure 1 The spinning machine 20 is provided with a drafting device 21, a spinning device 22, a yarn feeding device 23, a yarn clearer 38, and a yarn slack eliminating device sequentially from the upstream side along the yarn feeding direction in which the sliver 34 is produced by the sliver 27. 24 and take-up device 25. Furthermore, the spinning machine 20 further includes a piecing device 26 provided on a piecing cart 48 that moves among the plurality of spinning machines 20 between the yarn slack eliminating device 24 and the winding device 25 . The sliver 27 is stretched by the drafting device 21 to become a fiber bundle 33 , and the fiber bundle 33 is spun by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com