Square optical glass lens and method of producing the same

A technology of optical glass and manufacturing method, which is applied to glass manufacturing equipment, glass pressing, manufacturing tools, etc., and can solve problems such as lack of exhaust effect, difficulty in lens assembly, poor exhaust effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

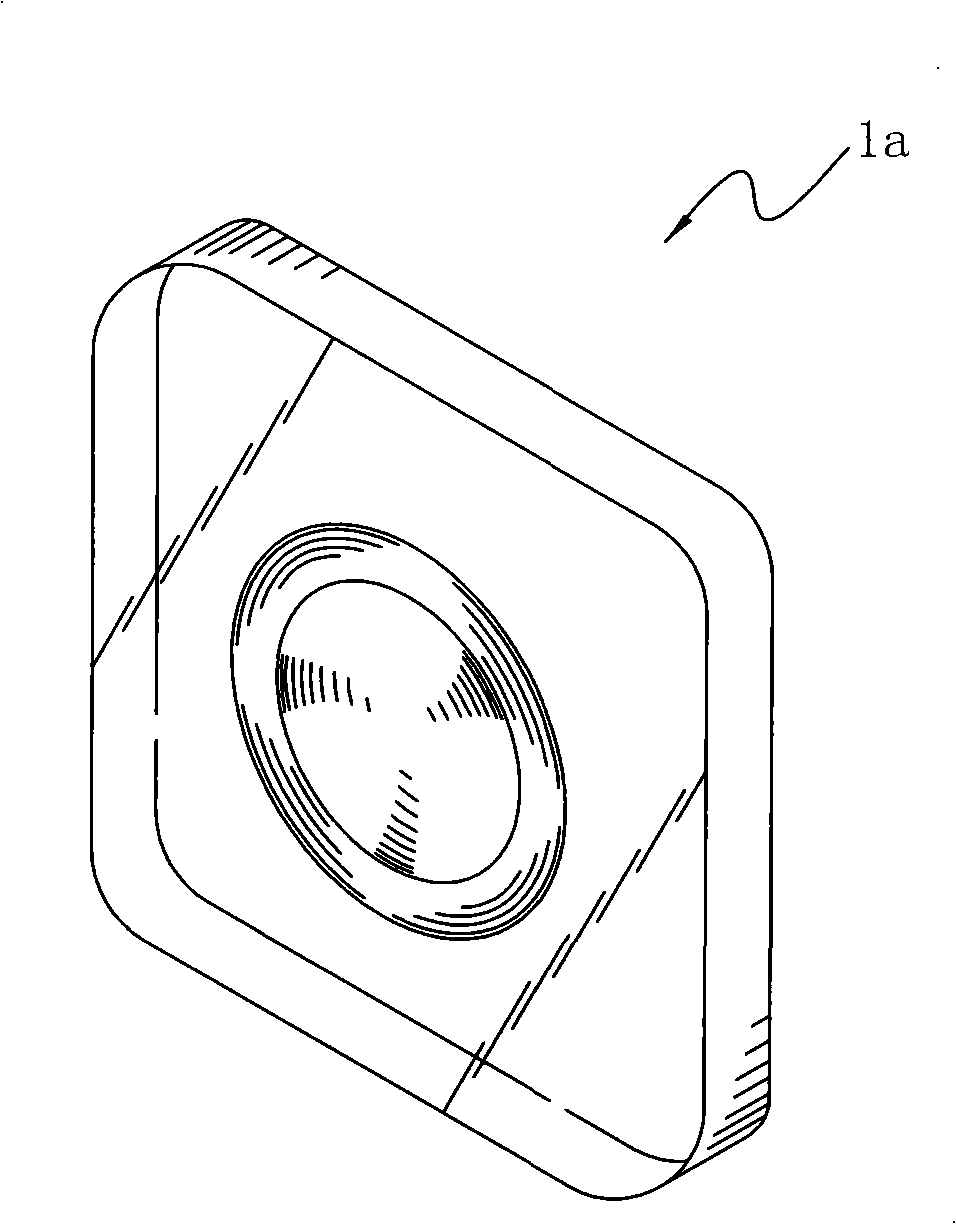

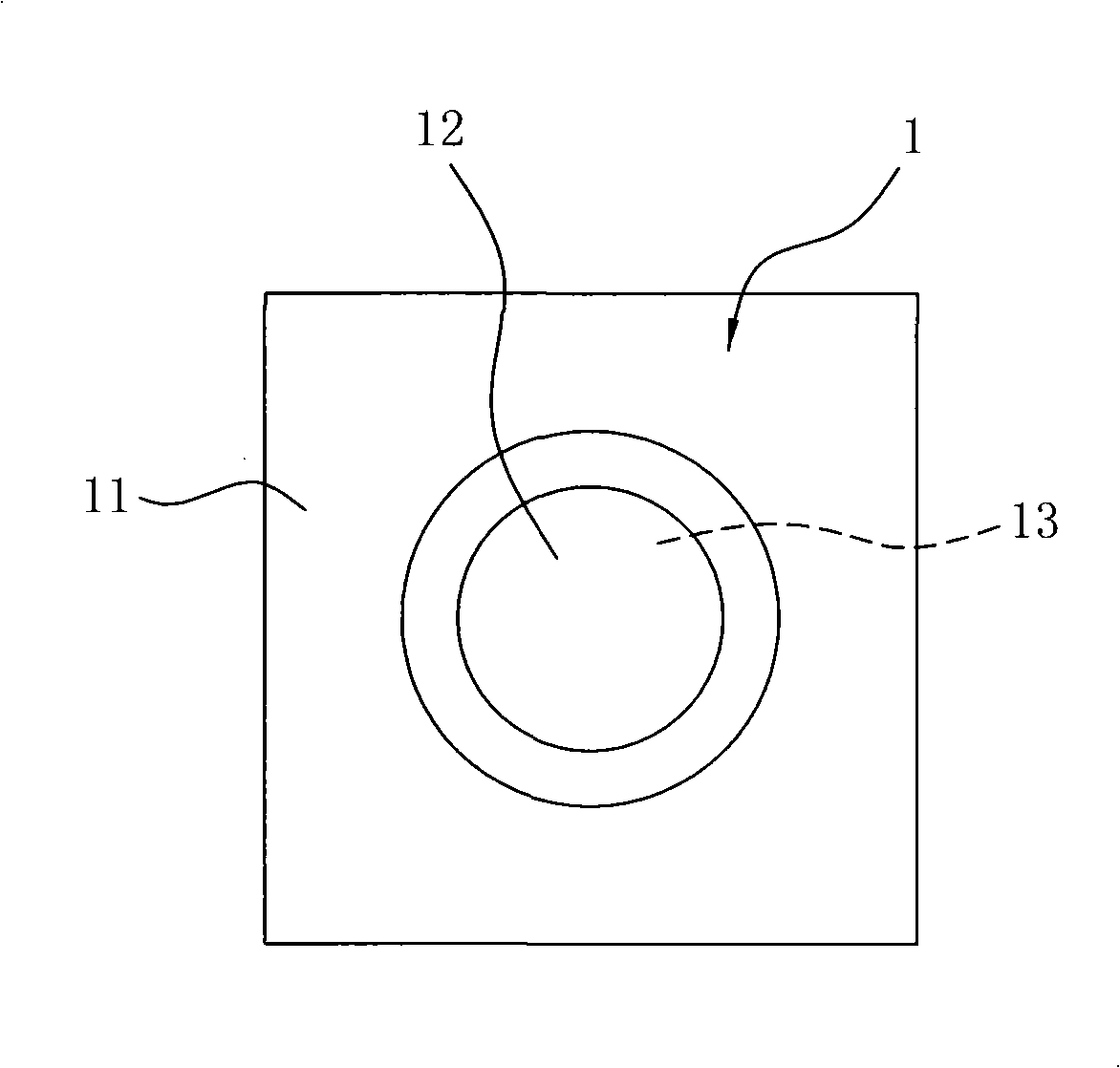

[0040] This embodiment is applied to a concave-convex aspherical square optical glass lens 1 such as image 3 , Figure 4 As shown, it is composed of a first optical surface 12, a second optical surface 13 and a shoulder 11, wherein the first optical surface 12 is a convex and aspheric surface, and the second optical surface 13 is a The surface is concave and aspherical, and the shoulder 11 is square and the four corners are all right angles, that is, the aforementioned right-angled square shoulder 11 .

[0041] In the square optical glass lens 1 of the present embodiment, its focal length is 1.87 mm, when assembled in the lens group 3 as shown in Figure 5, 6, can be applied to the diagonal size is 1 / 7 " (inch) below CMOS sensing assembly. The aspheric surface parameters of the convex aspheric surface of the first optical surface 12 of the present embodiment and the concave aspheric surface of the second optical surface 13 are as Table 1, and the aspheric surface formula used...

no. 2 example

[0060] This embodiment is applied to a biconvex aspheric square optical glass lens 1 as shown in Figure 10 and Figure 11, which is composed of a first optical surface 12, a second optical surface 13 and a rectangular square shoulder 11. Composition, wherein, the first optical surface 12 is a convex aspheric surface, the second optical surface 13 is a convex aspheric surface, the right-angle square shoulder 11 is square and the four corners are all right angles.

[0061] In the square optical glass lens 1 of the present embodiment, its focal length is 1.796mm, when assembled in the lens group 3 such as Figure 12 , Figure 13 , can be applied to CMOS sensing components with a diagonal size of 1 / 10 "(inch). The first optical surface 12 and the second optical surface of this embodiment are both convex aspheric surfaces, and the aspheric surface of the convex aspheric surface The parameters are shown in Table 2, and the aspheric formula used is the aspheric formula (1) described ...

no. 3 example

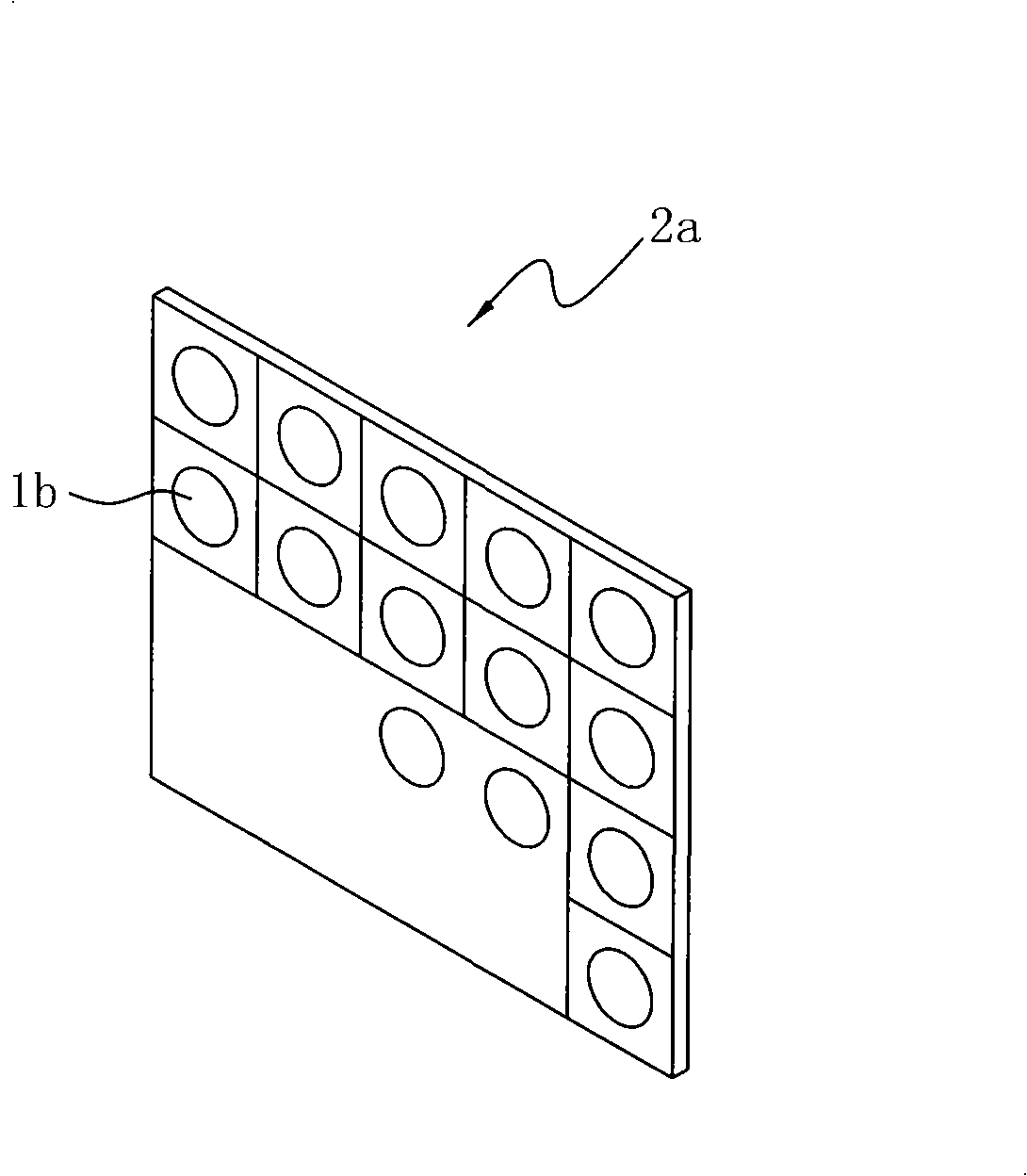

[0068] The present embodiment is to utilize the molding die that is provided with convex body to manufacture a square optical glass lens 1 such as Figure 17 shown. In the existing glass lens molding process, when the glass preform is placed into the mold cavity of the forming mold, there is generally a vacuuming process, the purpose of which is to discharge excess air in the mold cavity and avoid air residue Bubbles are caused in the mold cavity and affect the accuracy. Because the glass material will press the lower mold core to cause the air in the mold cavity of the lower mold core to be difficult to get rid of, there are many techniques to overcome this problem in the molding process of a single mold cavity; however, in the molding process of multiple mold cavities as in the present invention, That is, multi-cavity glass molding (multi-cavityglass molding), the gas removal is not easy. refer to Figure 14 and Figure 9 As shown, the lower mold core 52 of the forming d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com