Electric Valve

A technology of electric valve and valve needle, which is applied in the direction of lifting valve, valve details, valve device, etc. It can solve the problems of unreliable fixing of coil and valve body, loose stop parts, difficult assembly, etc., and achieve compact structure and high arm strength. Elastic, fixed and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

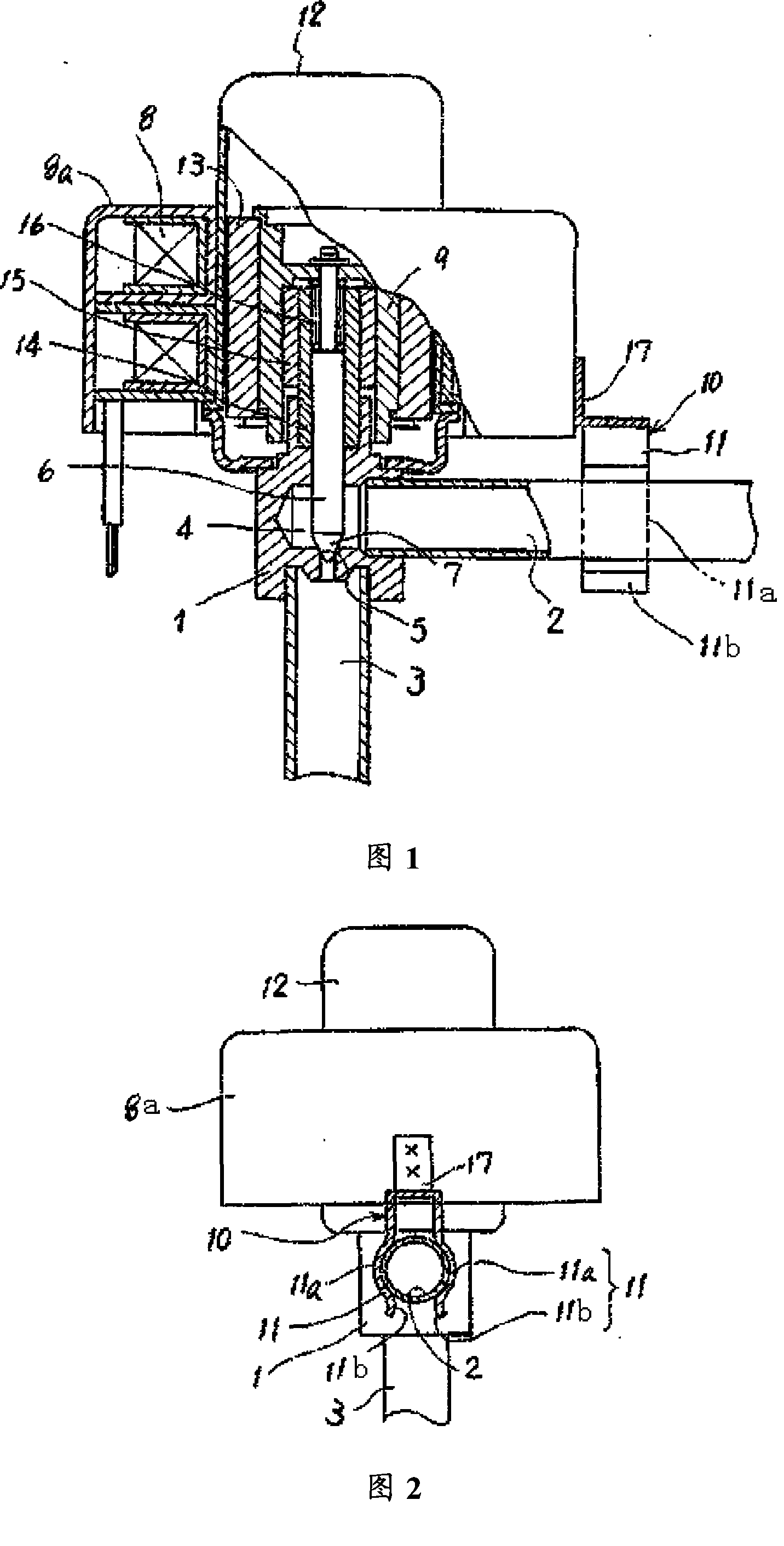

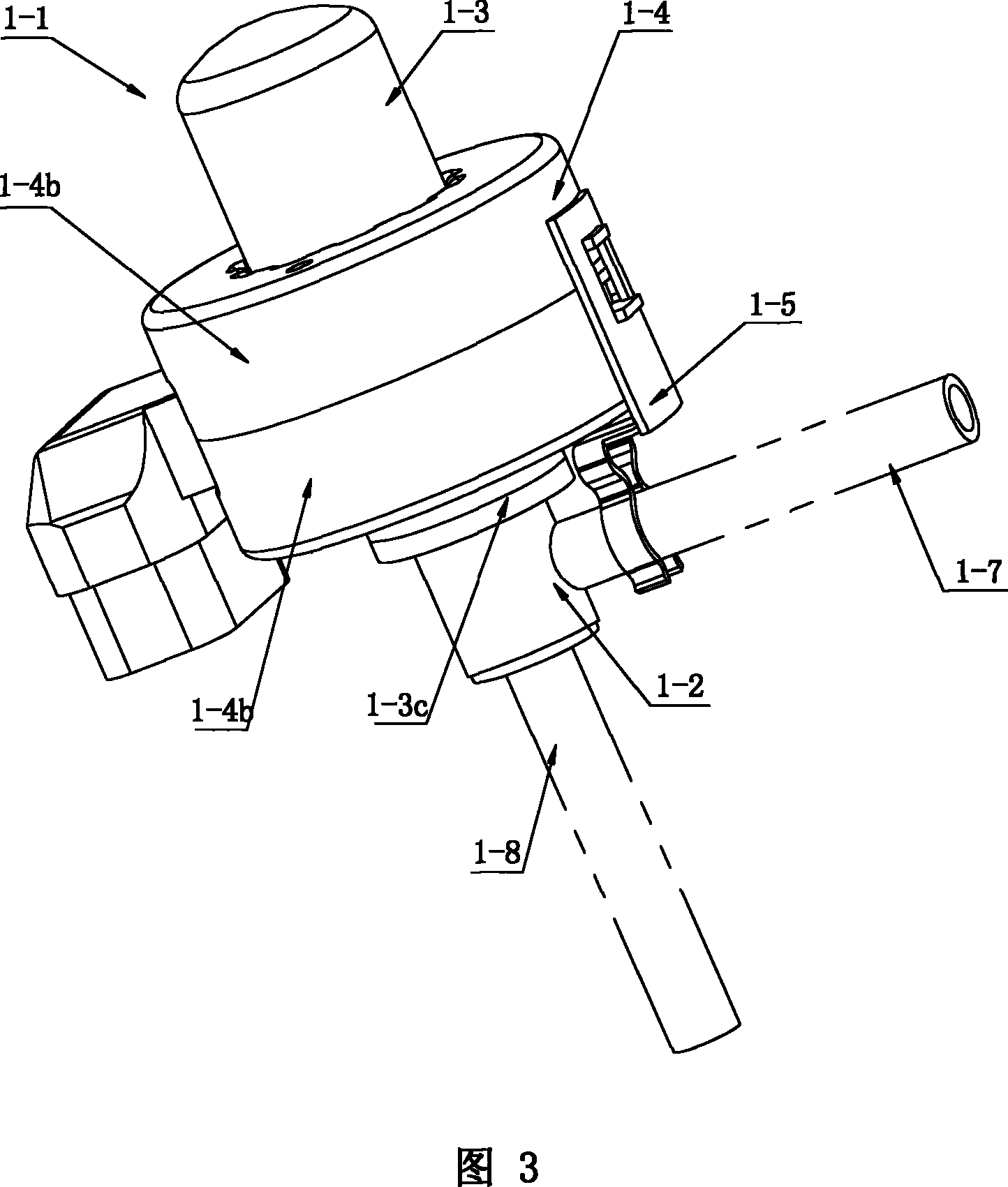

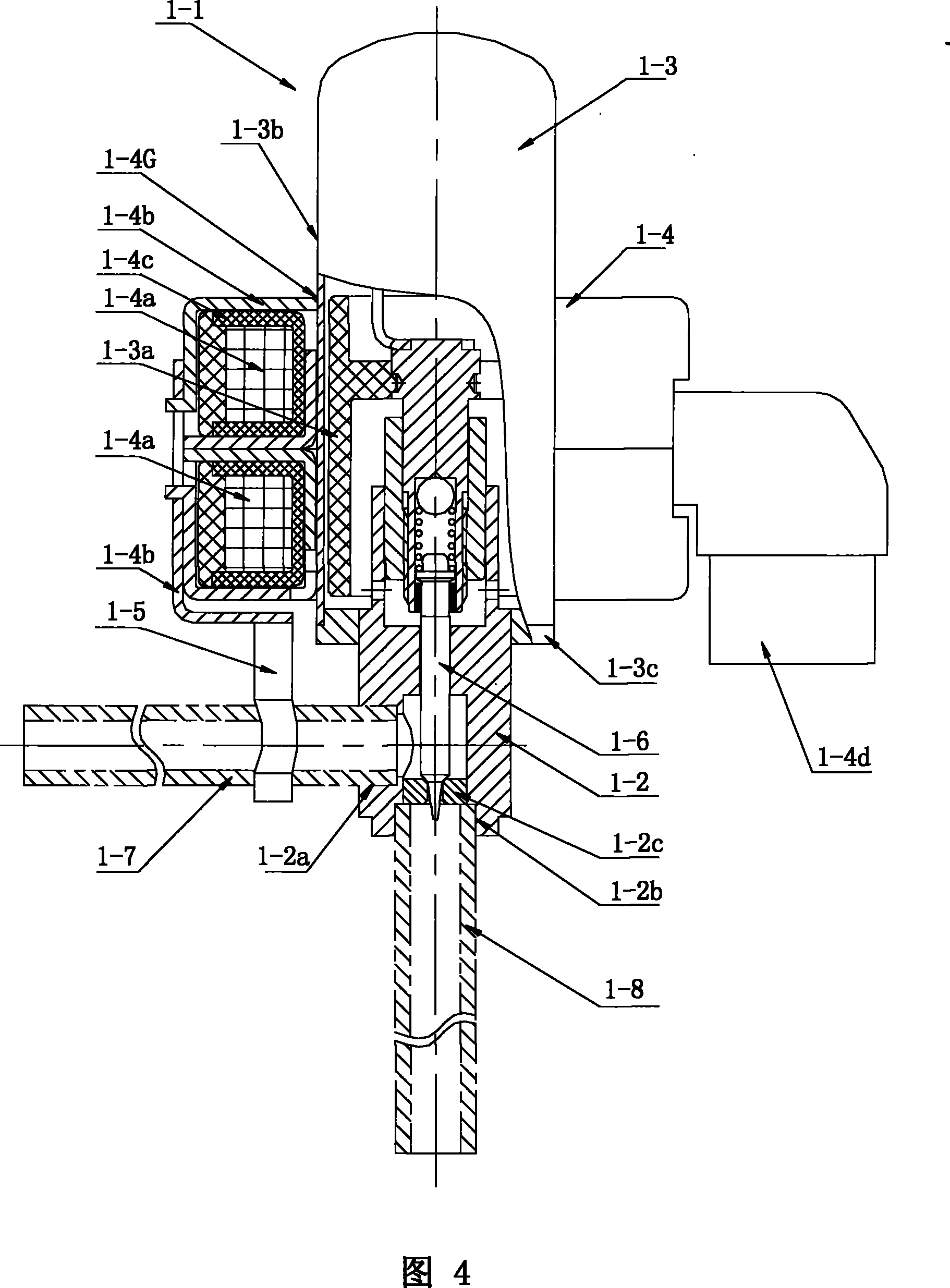

[0043] The present embodiment will be described in detail below in conjunction with the accompanying drawings.

[0044] Referring to Fig. 3, this figure is a three-dimensional structure diagram of the electric valve 1-1 of the present invention.

[0045] As shown in the figure, the electric valve 1-1 of the present invention consists of a valve seat 1-2, a rotor 1-3, a stator 1-4 sleeved on the outside of the rotor 1-3, a stopper 1-5 and a valve needle 1. -6 composition; the stepper motor composed of rotor 1-3 and stator 1-4 is set on the valve seat 1-2, and is used to drive the valve needle 1, valve needle 1-6 to move up and down to realize the valve needle 1-6 and valve seat 1 -2 to join or disengage. Arranged in the control system, the horizontal fluid inlet and outlet 1-2a and the vertical fluid inlet and outlet 1-2b of the valve seat 1-2 communicate with the horizontal fluid inlet and outlet pipe 1-7 and the vertical fluid inlet and outlet pipe 1-8 respectively. In orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com