Split joint type communication cabinet

A splicing and communication technology, which is applied in the field of communication cabinets, can solve problems such as the difficulty of changing the subdivision structure, large stress deformation of the welding structure, and rising temperature inside the cabinet, and achieves easy on-site engineering installation, high strength and stability, and maintenance-saving The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

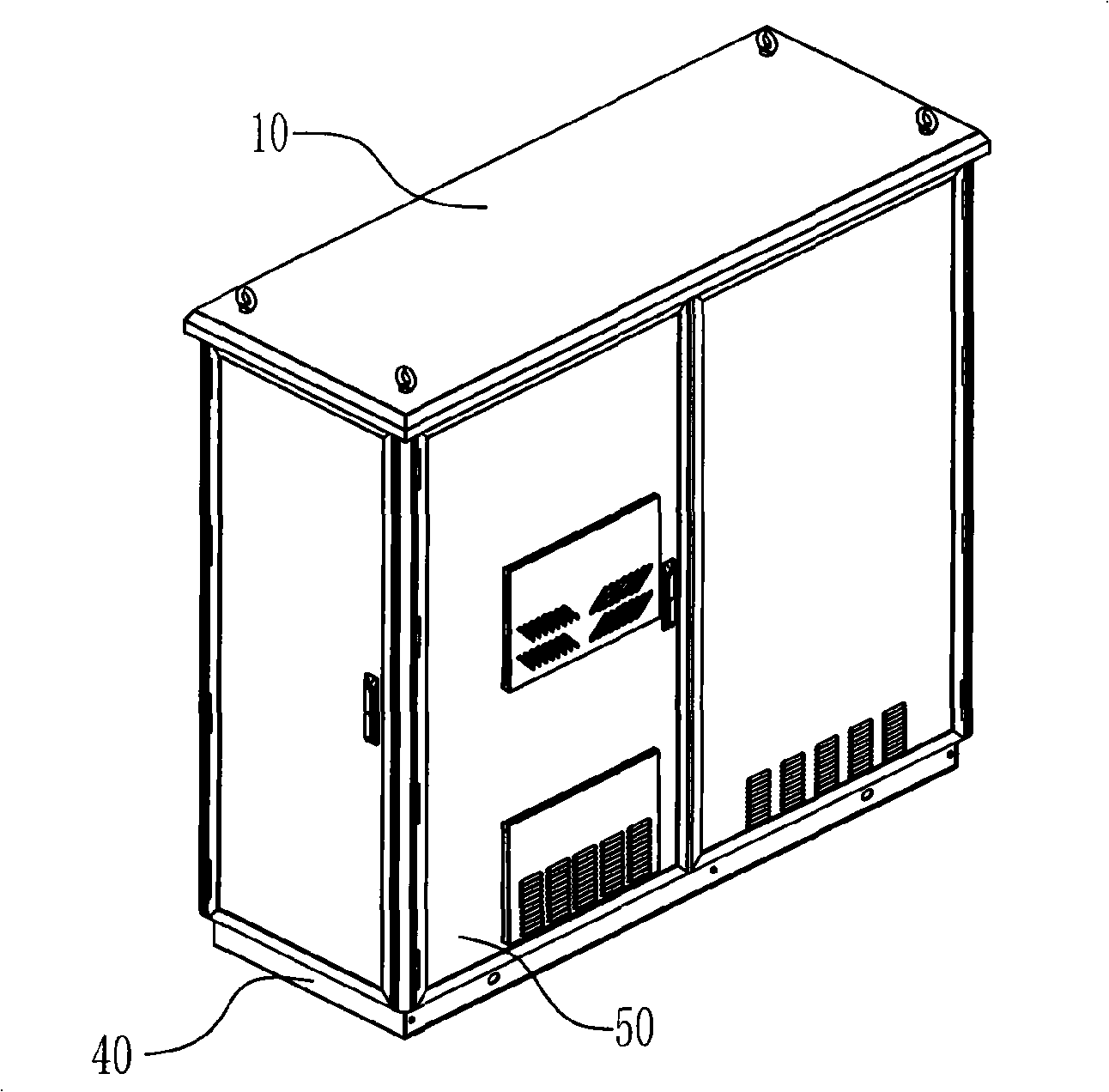

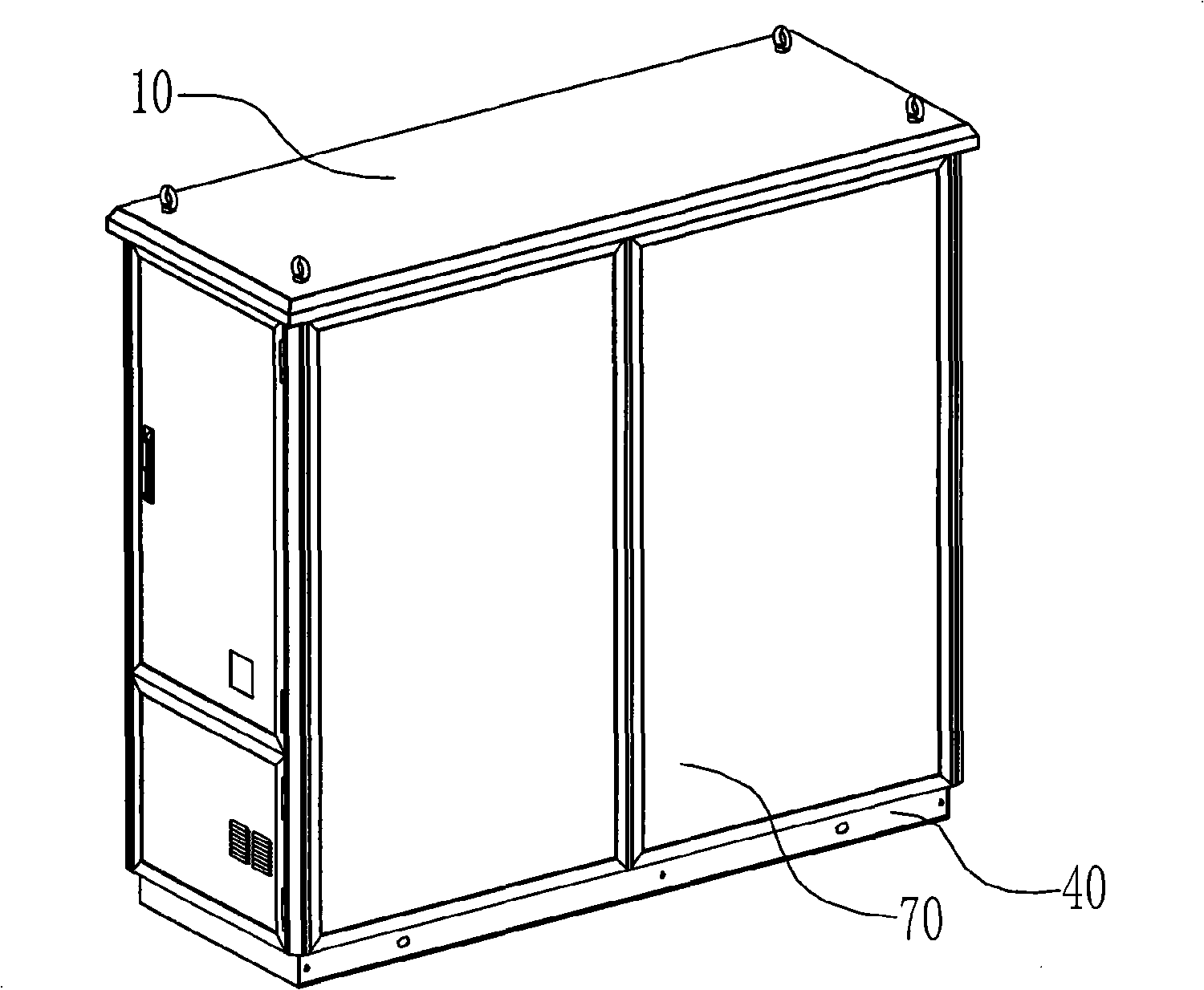

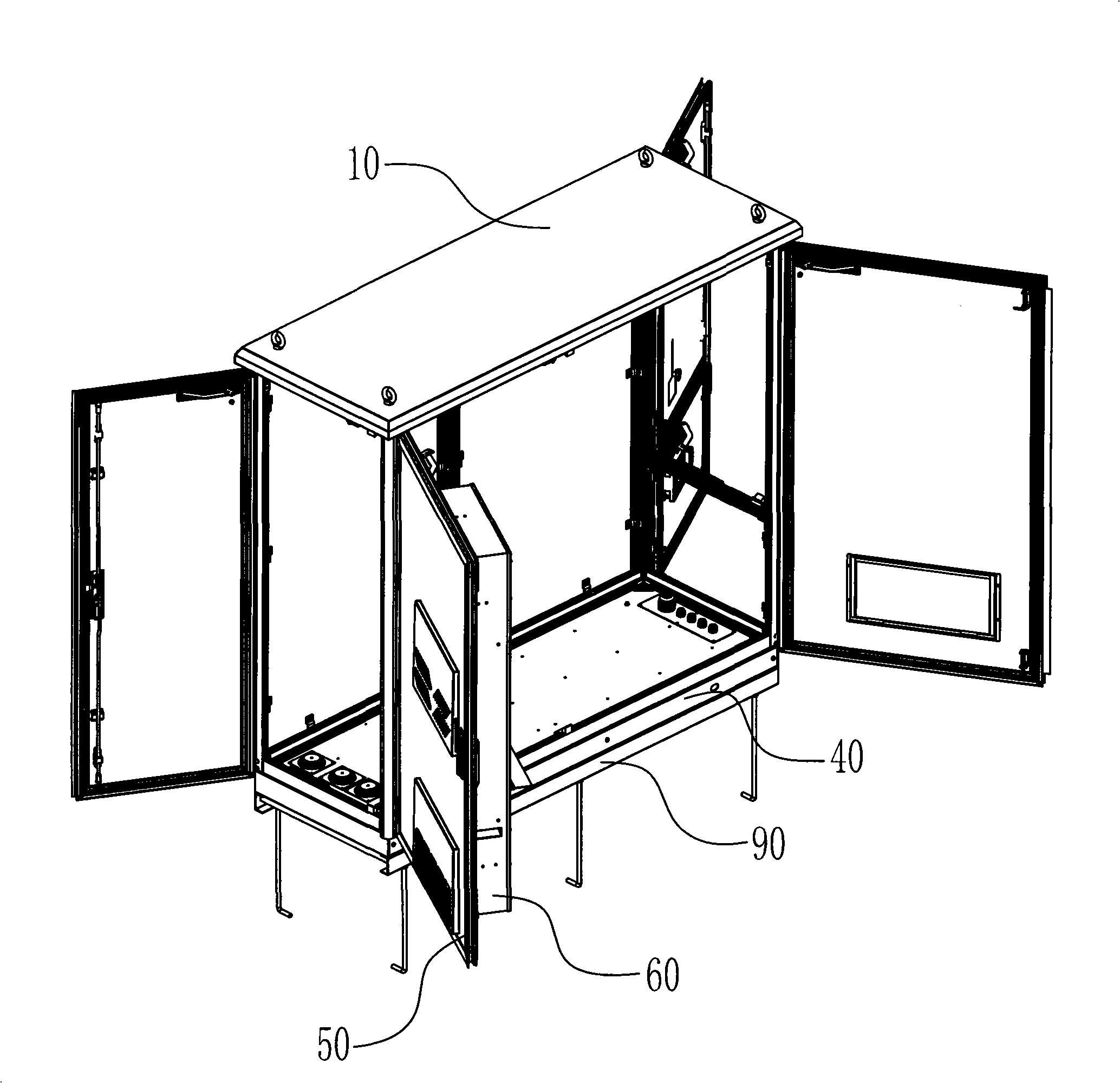

[0039] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the spliced communication cabinet includes a frame 20 and an outer cover, and the outer cover includes a top cover 10, a bottom plate 30, a base 40, a door panel 50, and a side plate 70; after the bottom plate 30 is fixed to the bottom of the frame 20 through a screw connection, the frame The bottom of the frame 20 is fixed to the base 40 through a threaded connector, and the top cover 10 is fixed to the top of the frame 20 through a threaded connector, so that the top cover 10 and the bottom plate 30 cover the top and bottom surfaces of the frame 20; and threaded connectors (see Figure 10 ) is embedded and connected to the frame 20, one side of the door panel 50 is hinged on the frame 20 through a hinge 501, and the other side is provided with a door lock 502 for lockin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com