Method for burning and carving body surface of livestock and poultry with laser beam

A laser beam and carcass technology, applied in the field of laser beam burning, can solve the problems of inability to meet the production line and production process of slaughterhouses, pollution of livestock and poultry carcasses, inability to change information content, etc., and achieve effective management of wholesale enterprises and consortia. , The effect of solving the low management level and promoting self-discipline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

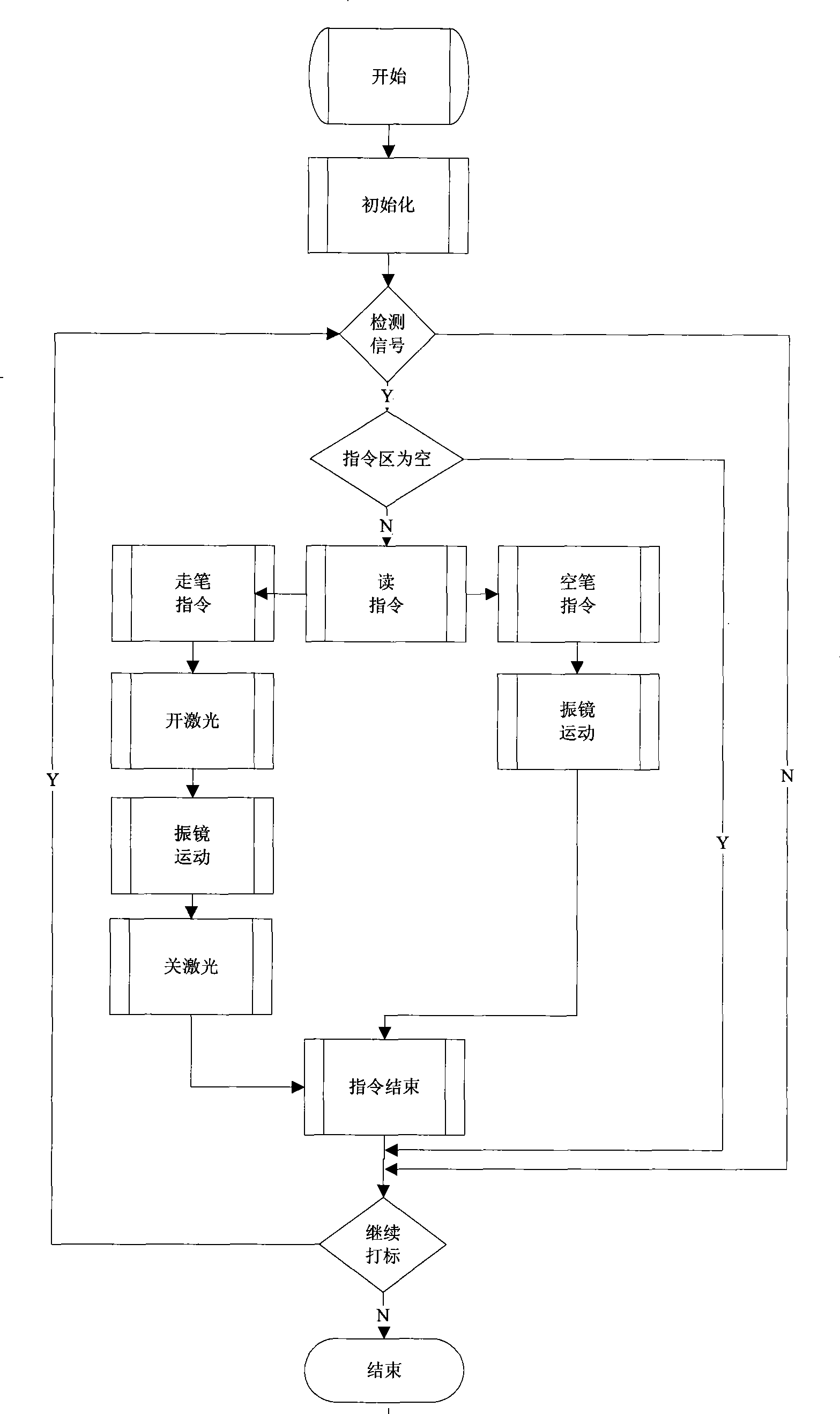

[0031] The specific embodiment of the present invention is that the laser beam is applied to burn the body surface of livestock and poultry

[0032] Steps include:

[0033] Step 1: Input burning information into the laser equipment controller;

[0034] Step 2: Put the carcass of livestock and poultry statically, or put it on the running assembly line, so that the surface of the carcass of livestock and poultry faces the laser equipment;

[0035] Step 3: a laser, a vibrating mirror, a sensor, a beam expander, an automatic zoom device, and a focusing mirror are installed in the laser equipment, and the laser equipment is controlled by a controller;

[0036] Step 4: The sensor detects that the carcass of livestock and poultry enters the laser marking area, and outputs a signal to the controller;

[0037] Step 5: The controller controls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com