Parallel type three-shaft mainshaft head structure without accompanied movement

An accompanying motion, parallel technology, used in large fixed members, metal processing mechanical parts, metal processing equipment, etc., can solve the problems of complex kinematics, increased difficulty, complex spindle head structure manufacturing and assembly process, etc., to achieve high precision , the effect of conducive to accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A parallel three-axis spindle head structure without accompanying motion proposed by the present invention is described in detail below with reference to the accompanying drawings and embodiments.

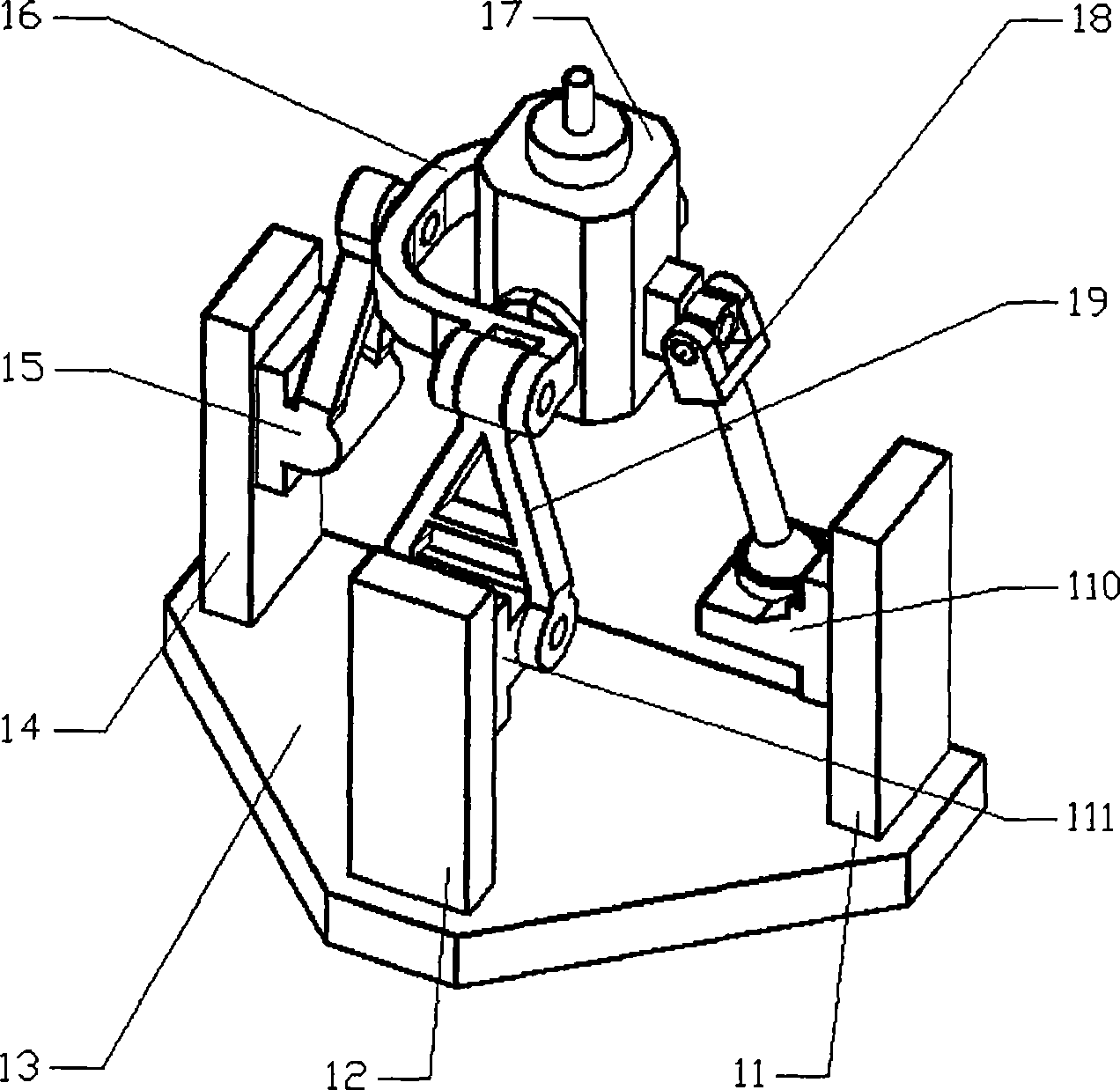

[0017] The structure of the first embodiment of the present invention, such as figure 1 As shown, the structure includes a moving platform 17 on which the main shaft is installed, and a fixed platform, which is composed of a platform base 13 and columns 11, 12, 14 consolidated into one; Between the first, second and third branches, the first branch includes a first input member 15, a first connecting member 16 and a kinematic pair, and there are three kinematic pairs, one of which is connected to the first A moving pair between the input member 15 and the fixed platform column 14, one is the first rotating pair connected between the first input member 15 and the first connecting member 16, and the other is connected to the first connecting member 16 and the second rotary pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com