Apparatus and method for conditioning dampening solution for an offset printing press

A technology of a processing device and a processing method, applied in the field of ion exchangers, can solve problems such as the limitation of electrical conductivity, and achieve the effect of improving processing and high printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

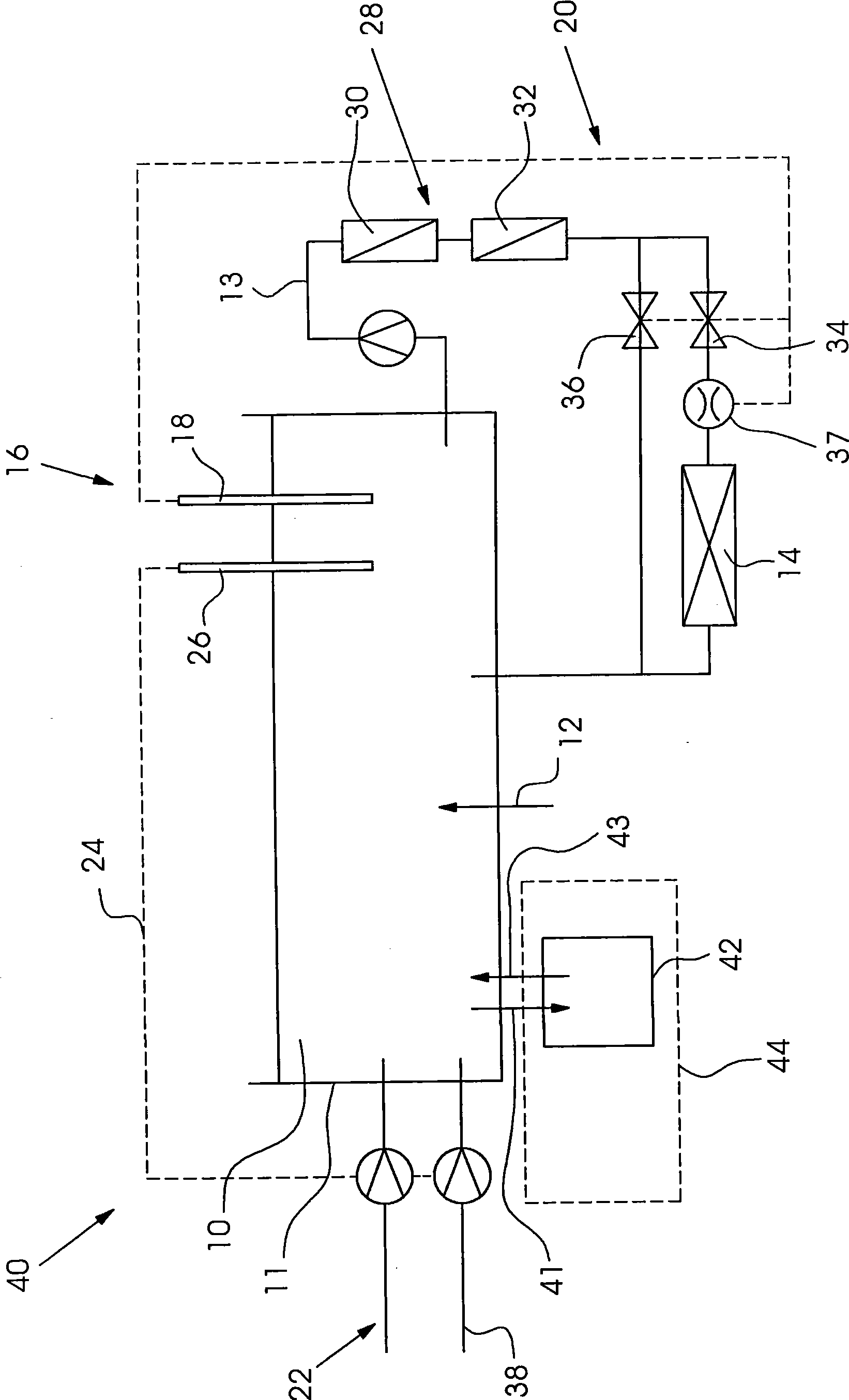

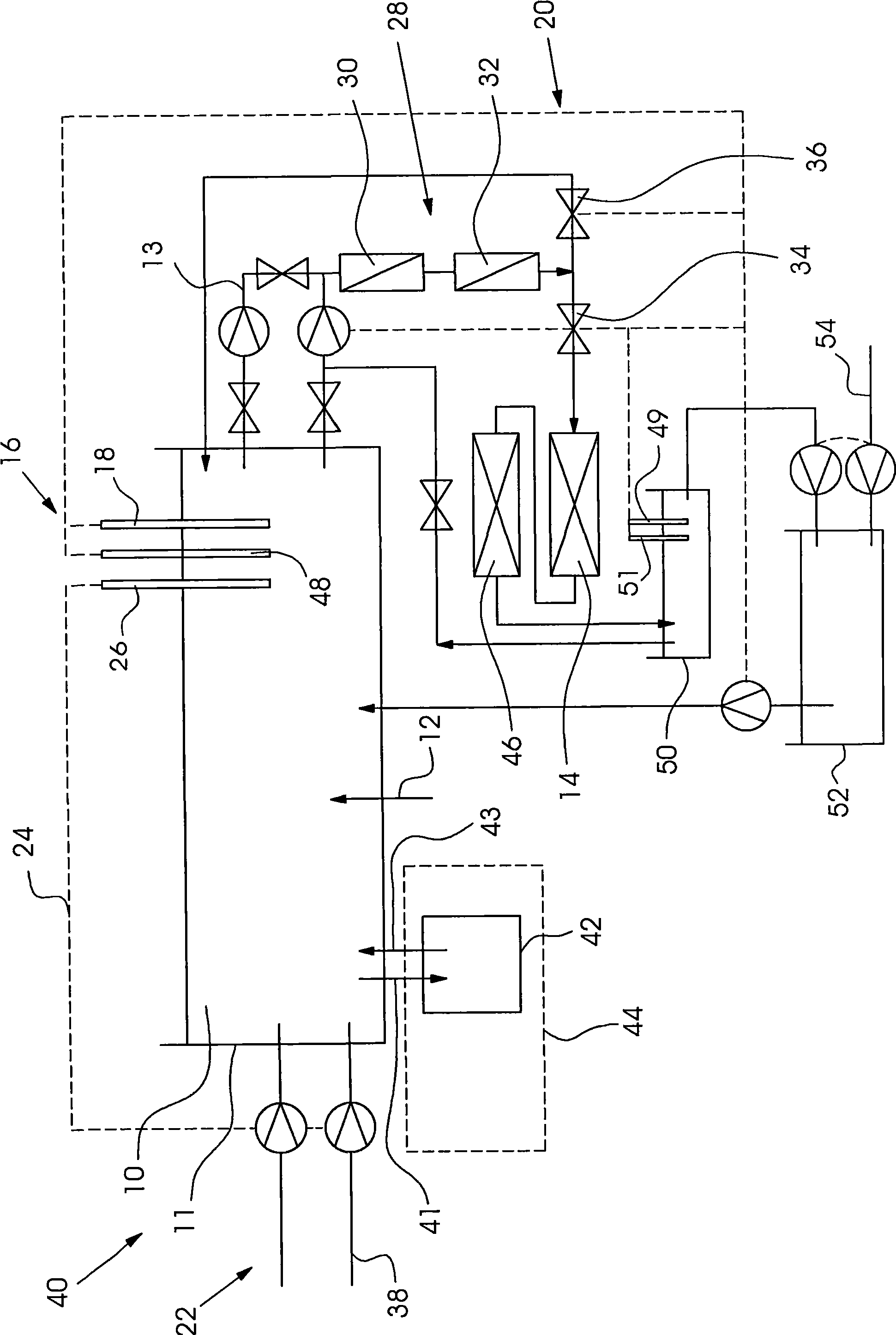

[0035] figure 1A preferred embodiment of the dampening agent 10 treatment device according to the invention is shown, suitable for isopropanol-free or low-isopropanol offset printing. An offset printing machine 44 comprises a printing unit 42 and a dampening agent device 40 interacting with the printing unit 42 , from which dampening agent reservoir 11 can be passed through the inlet device 41 . It reaches the printing unit 42 and returns from the printing unit 42 to the dampening agent reservoir 11 via the return unit 43 . Hardened fresh or raw water and customary wetting agent additives are usually supplied to the wetting agent reservoir 11 via a filling feed 38 which can be closed by means of a valve. The supplied wetting agent 10 is 2+ and Mg 2+ The ionic titration or water hardness measurement 16 by means of a water hardness sensor should have a hardness value of 8° to 16° dH (German hardness), preferably 8° to 12° dH. Ca in the ion-sensitive electrode 18 2+ For ion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com