Forward, reverse and boosting integrated speed variator of motor vehicle

A technology for motor vehicles and transmissions, which is applied to instruments, vehicle components, mechanical equipment, etc., can solve the problems of increased installation and maintenance economic costs, increased installation and maintenance operations, and scattered installation layouts, and achieves compact structure and perfect rationality. , Occupy space compact and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

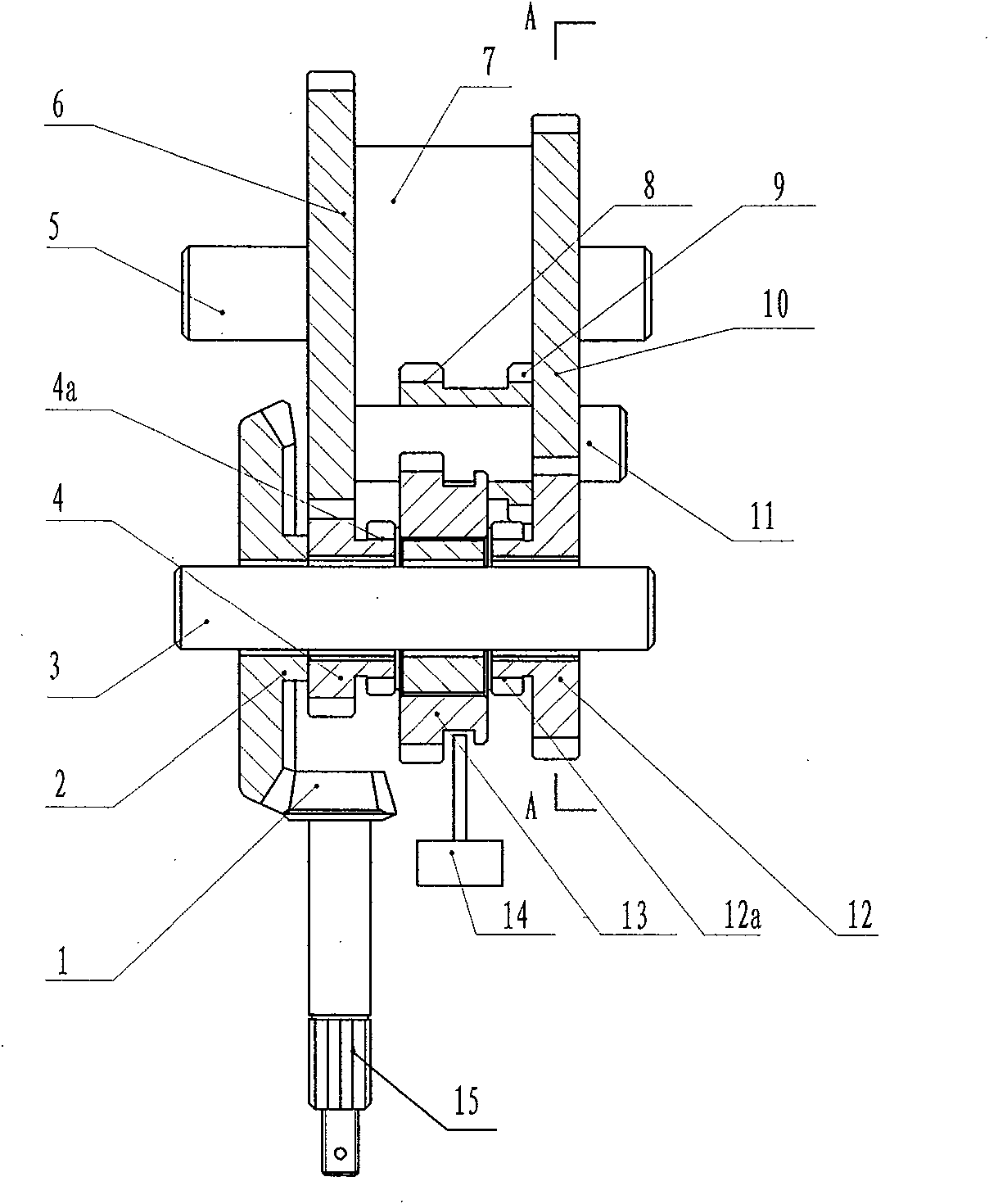

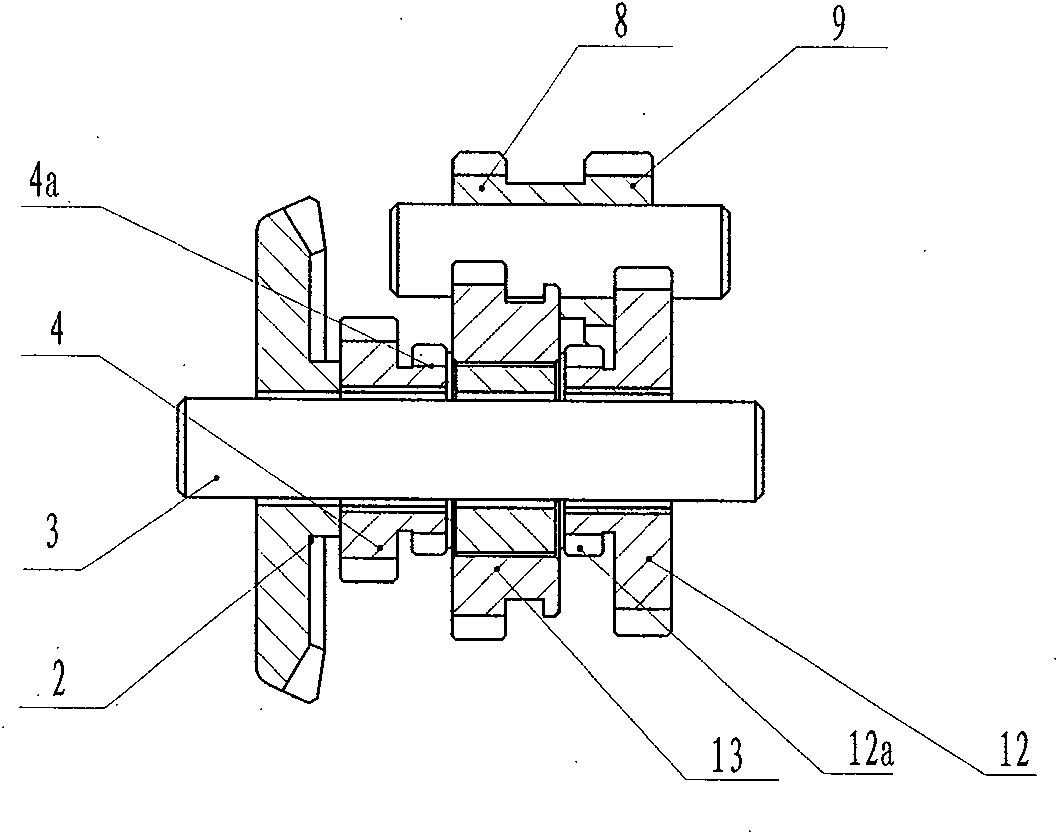

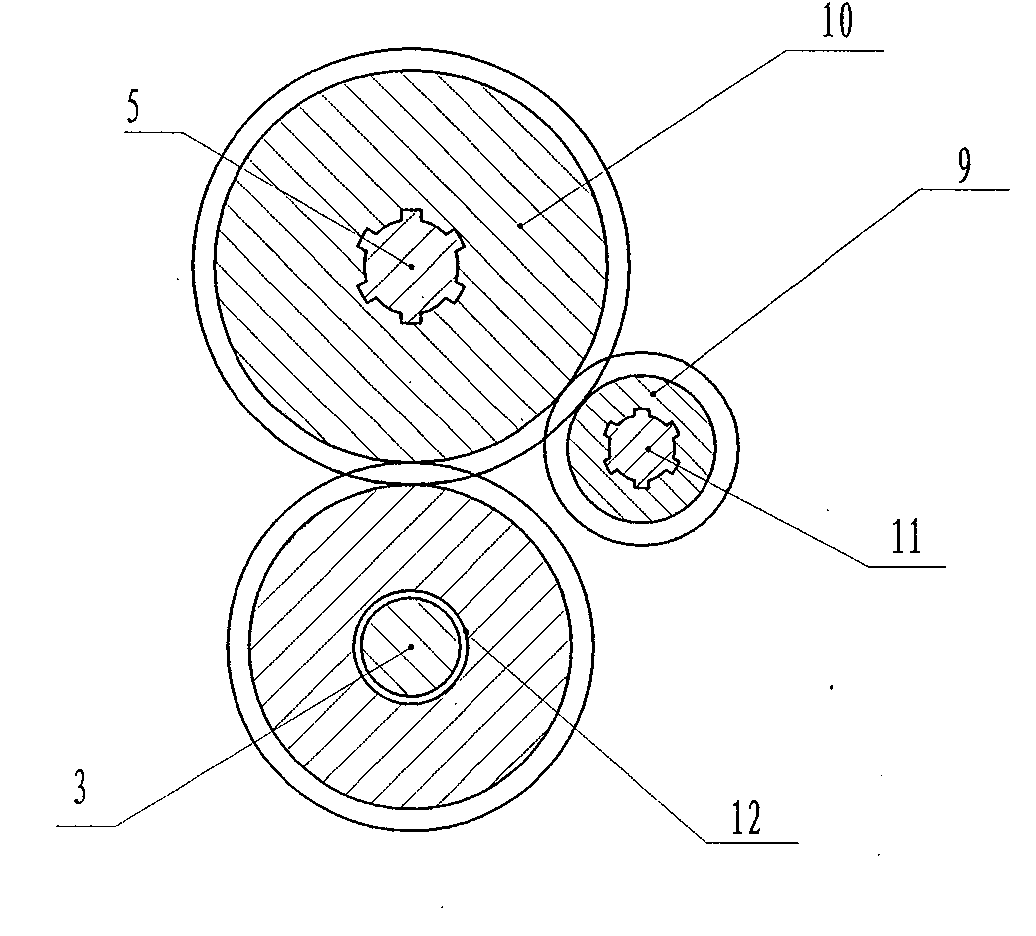

[0020] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the meshing section of the driving gear of reverse gear and the intermediate gear of reverse gear, image 3 for figure 1 A sectional view along A-A, as shown in the figure: the motor vehicle forward, reverse and afterburning integrated transmission of this embodiment includes a power input shaft 15, an intermediate shaft 3 and a power output shaft 5, and the power output shaft 5 includes a central coaxial Two shaft sections, the two shaft sections cooperate through the differential 7 to reasonably configure the rear wheel speed; the power input shaft 15 cooperates with the intermediate shaft 3 through a transmission device. In this embodiment, the power input shaft 15 and Between the intermediate shafts 3 is a cross-shaft transmission, and the transmission device includes a driving bevel gear 1 that is meshed with the power input shaft 15 in the circumferenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com