Forklift speed variator

A transmission and forklift technology, applied in transmission parts, gear transmissions, belts/chains/gears, etc., can solve the problems of driver's nervous operation, lack of synchronizers, poor drivability, etc., to achieve clear gears and improve efficiency , the effect of compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

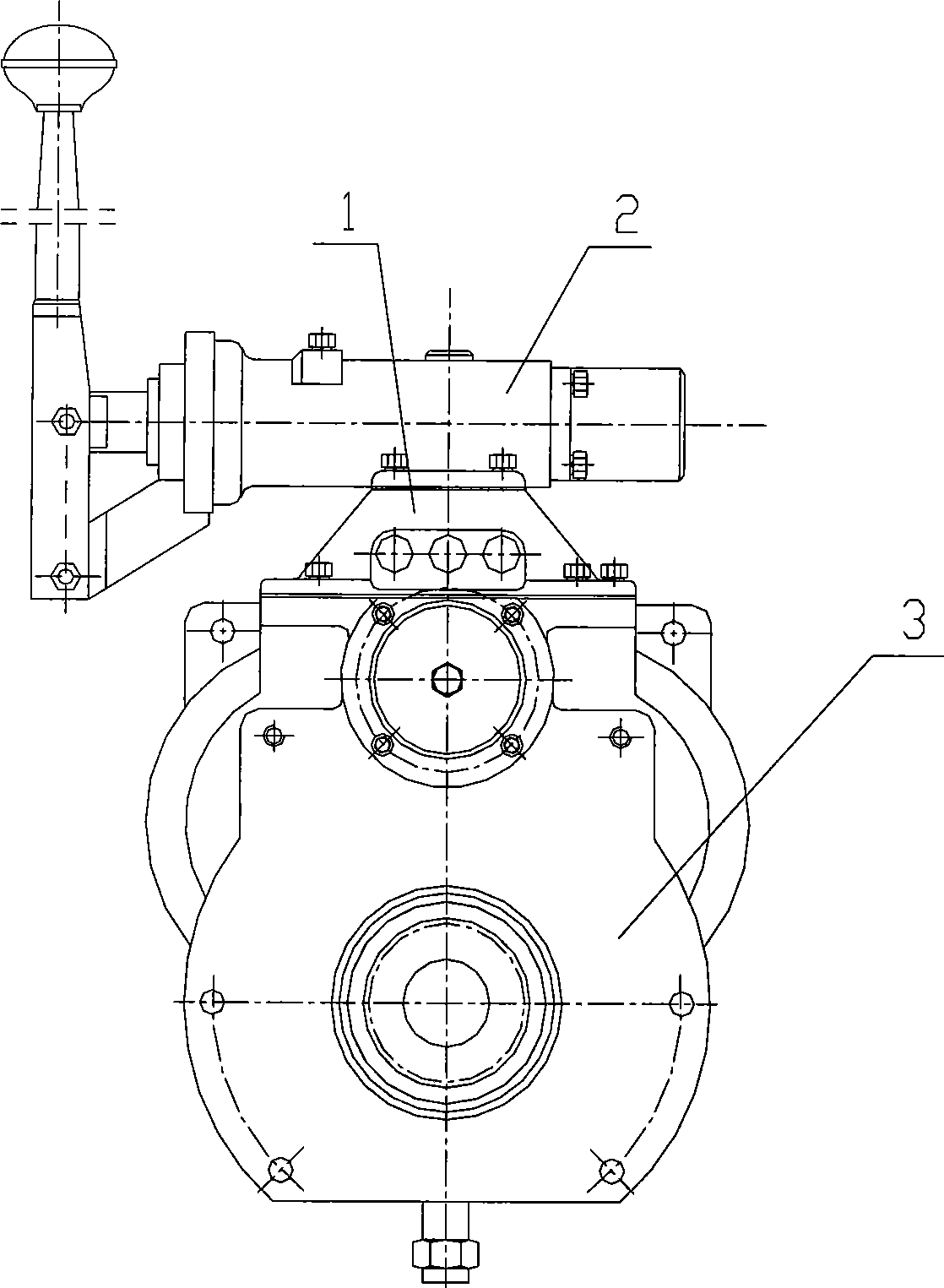

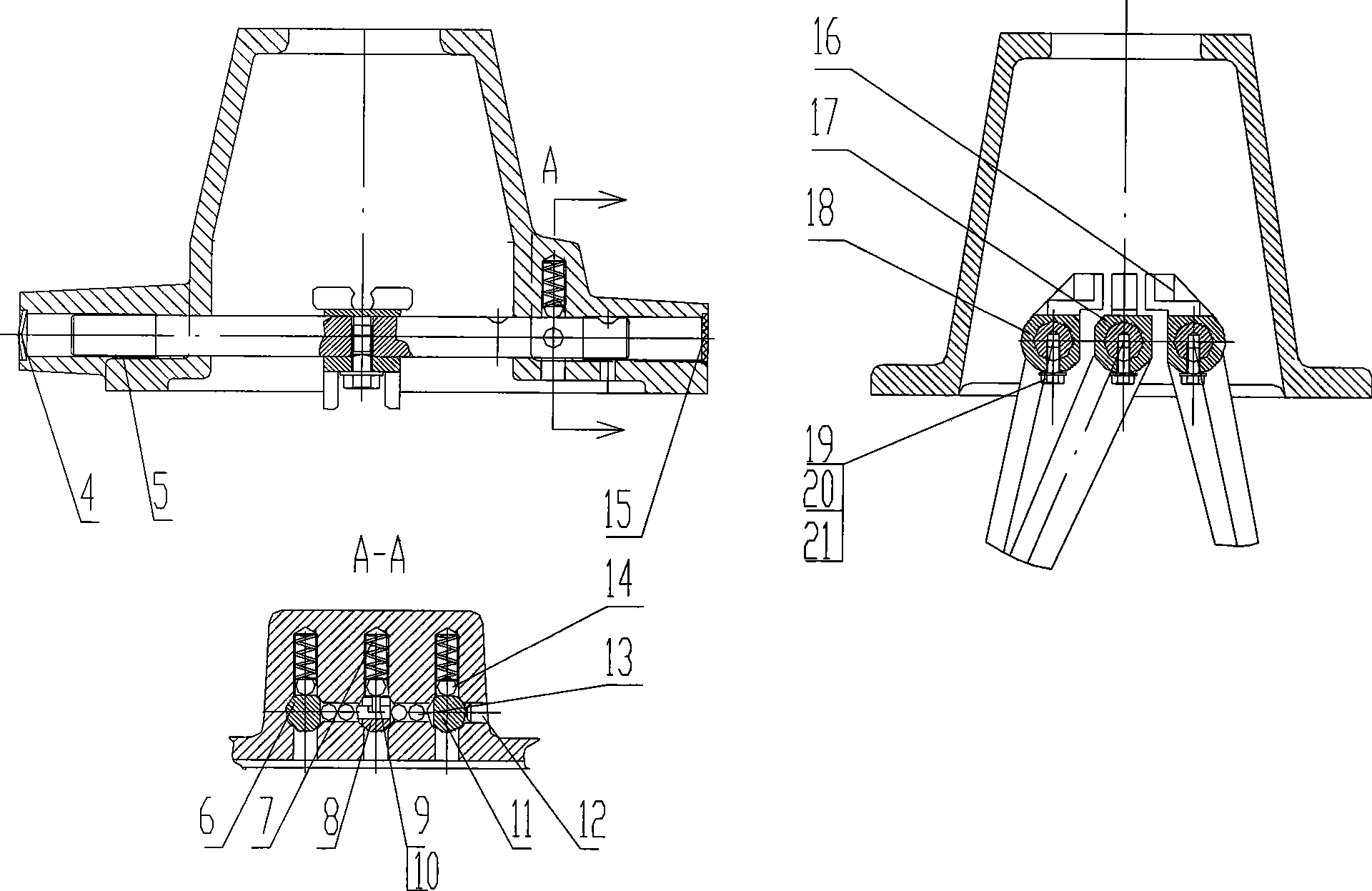

[0018] see figure 1 , 2 , 3, 4, 5 The present invention has a forklift transmission with synchronizer shifting, which is composed of an upper cover assembly (1), a shifter assembly (2) and a gear shifting part (3).

[0019] The upper cover assembly (1) consists of a sheet plug (4), an upper cover (5), a shift fork shaft (6), a spring (7), a first and second gear shift fork shaft (8), a pin (9), a lock pin (10), reverse first and second gear fork shaft (11), block (12), steel ball (13), steel ball (14), block (15), reverse first and second gear fork (16), first and second gear Shift fork (17), third gear shift fork (18), hexagon head bolt with hole (19), spring washer (20), steel wire (21) etc. form. It is characterized in that: the first and second gear shift forks (16), the first and second gear shift forks (17), the third gear shift forks (18) pass through the shift fork shaft (6) and connect with the synchronizer.

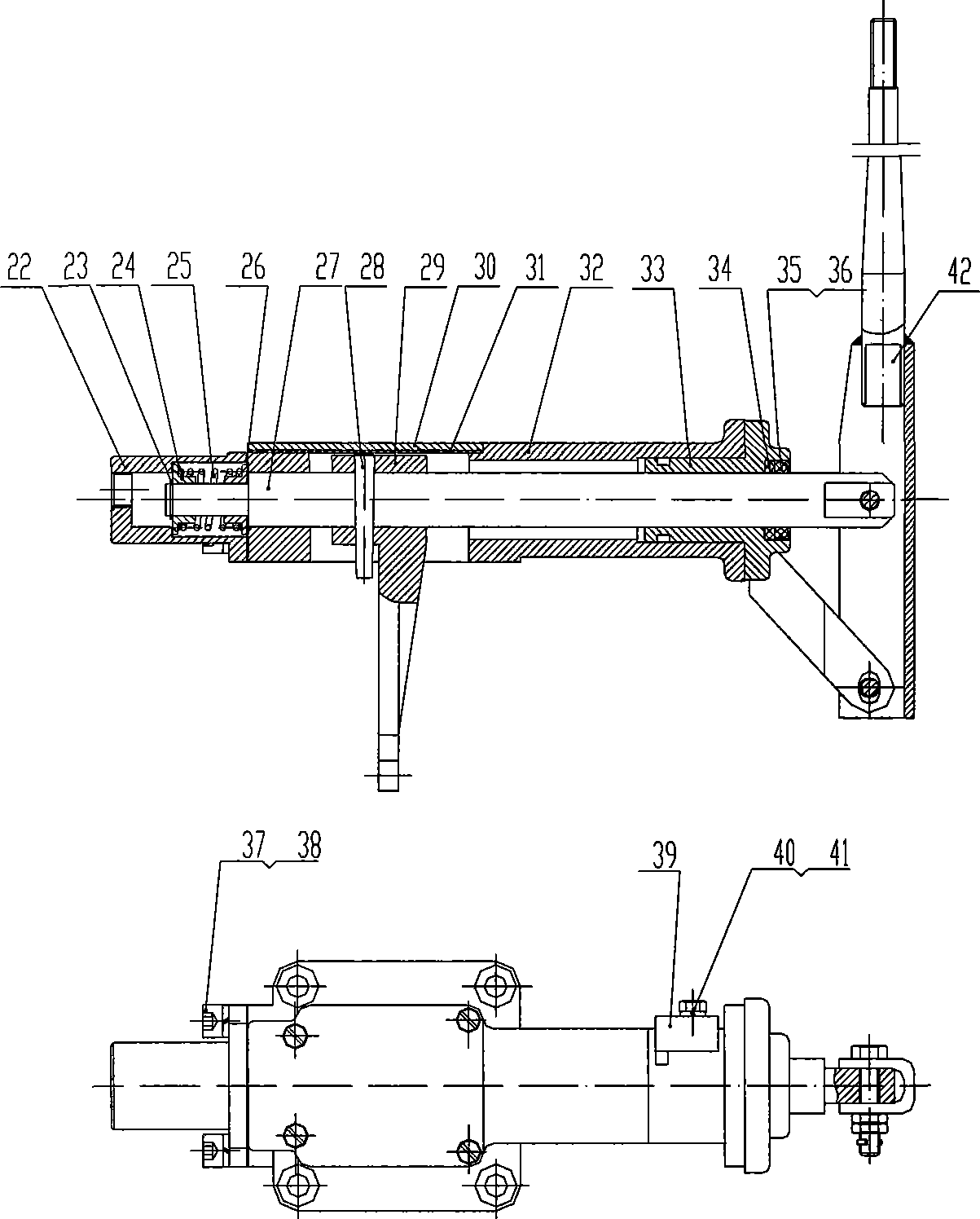

[0020] Shifter assembly (2), consisting of shifter cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com