Flue gas sampling probe

A sampling probe and flue gas technology, applied in sampling devices and other directions, can solve problems such as easy corrosion, easy thread corrosion, inconvenient maintenance, etc., and achieve the effects of prolonging the maintenance period, improving the degree of purification, and stable and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

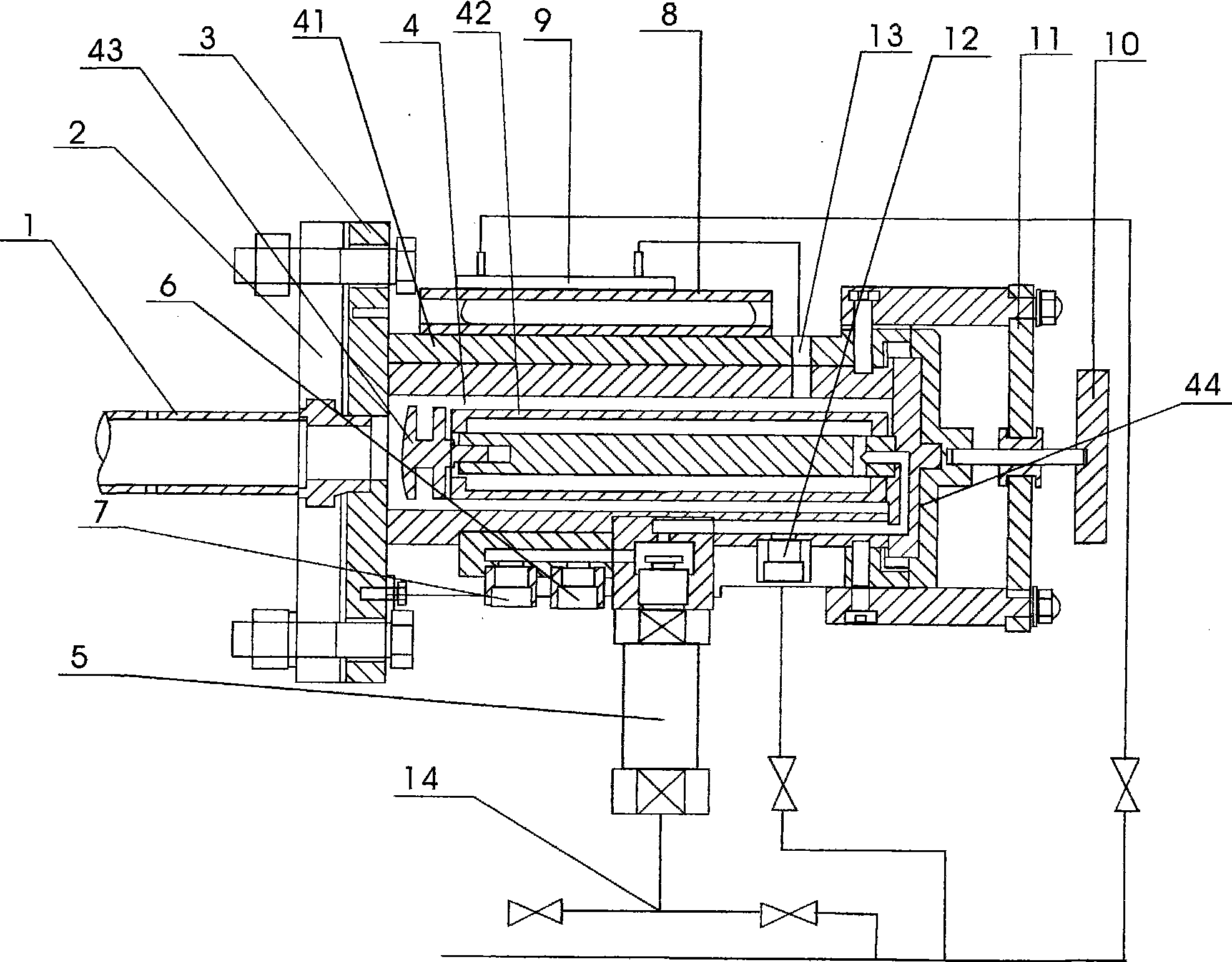

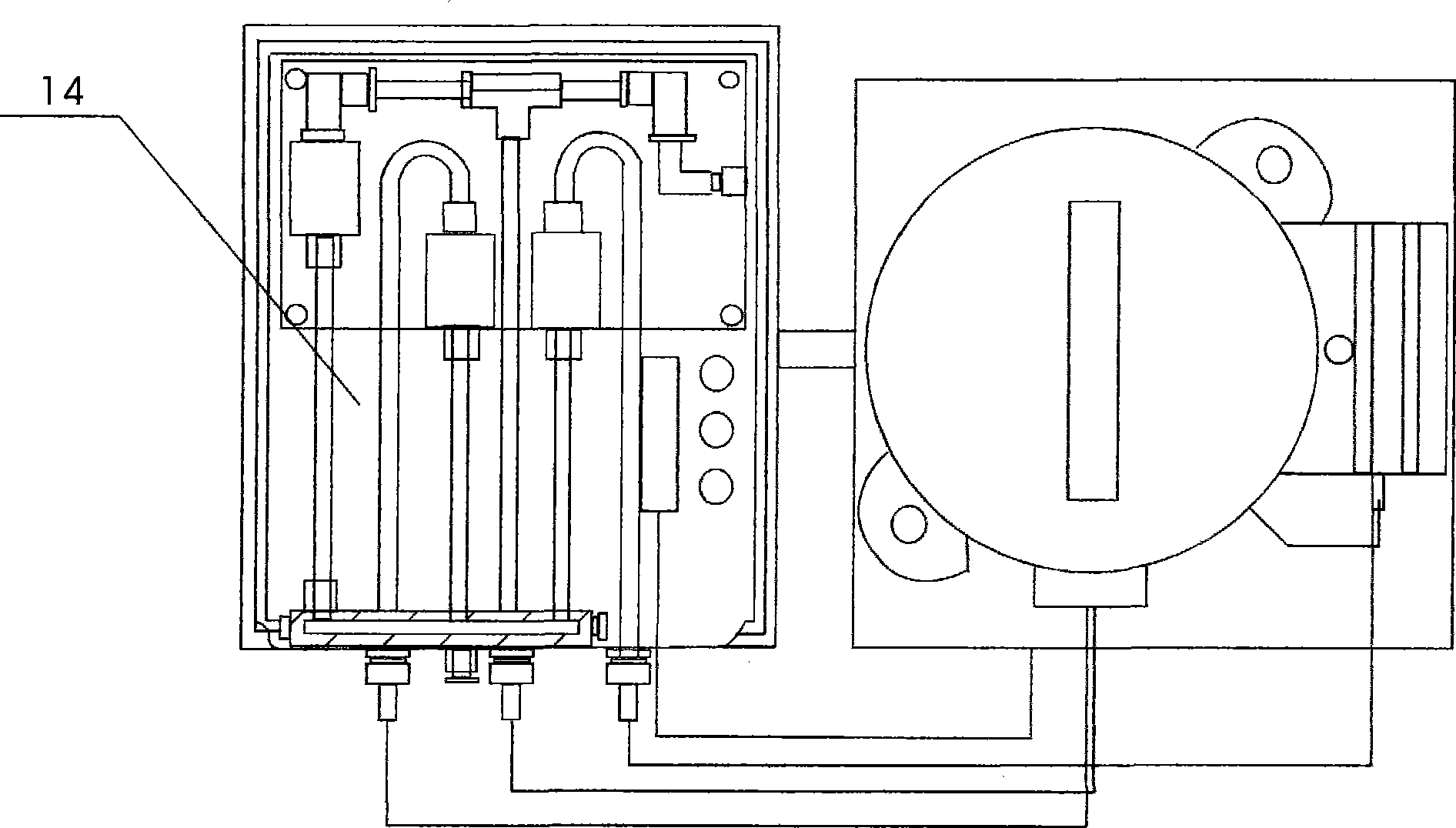

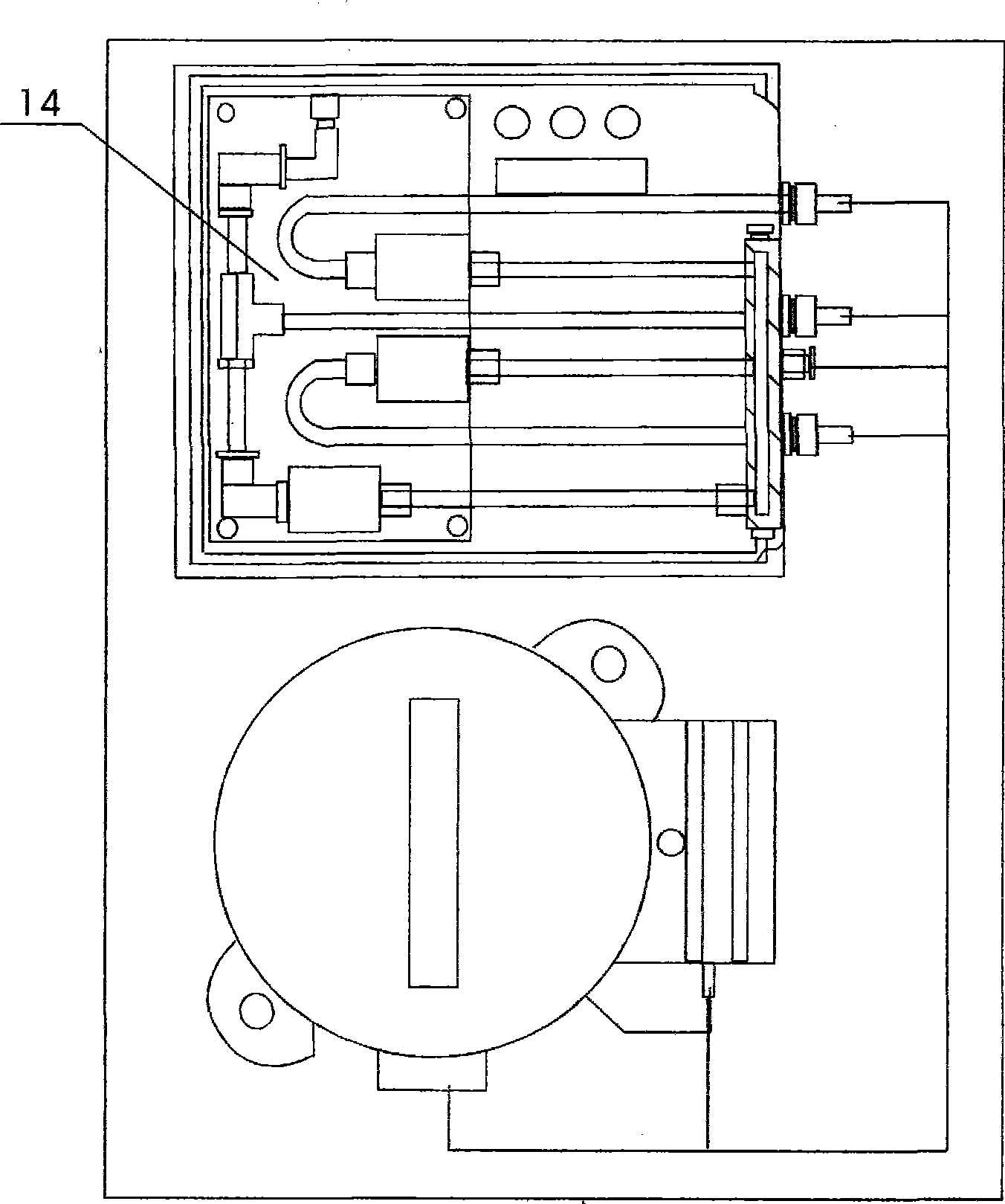

[0019] As shown in the figure, the present invention mainly includes a sampling pipe 1, a sampling flange 2, a sampling probe mounting plate 3, a filter 4, a cylinder 5, a standard air inlet 6, a sample gas outlet 7, an electric heater 8, and a blowback The air heater 9, the jacking screw 10, the lever 11, the inner back-blowing air port 12, the outer back-blowing air port 13 and the electrical air circuit 14 are characterized in that the sampling pipe 1 and the sampling probe mounting plate 3 are connected in a threaded manner, and the sampling The flange 2 and the sampling probe mounting plate 3 are fixedly connected by bolts, the filter 4 and the sampling probe mounting plate 3 are fixed together, the electric heater 8 and the blowback air heater 9 are all installed on the filter housing 41, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com