Method for determining a refuse filling level

A grinder and material level technology, which is applied to the material level field of the drum, can solve the problem of being unsuitable for the grinder to rotate, and achieve the effect of low implementation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

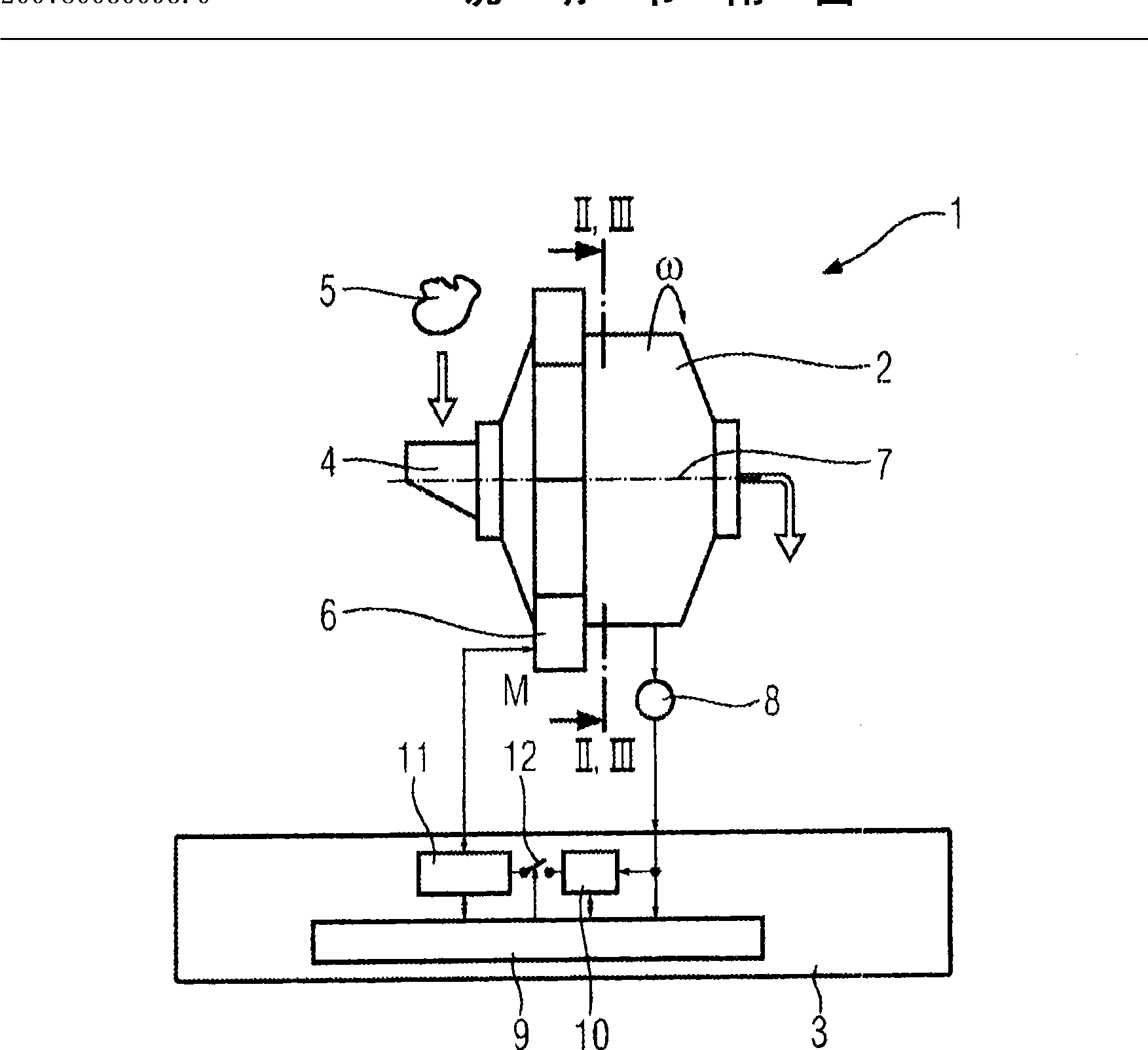

[0040] figure 1 An exemplary embodiment of a grinder 1 with a drum 2 and a control and regulation unit 3 is shown schematically. The attritor 1 is an ore grinding machine configured as a ball mill or as a SAG attritor. The drum 2 is connected to a feed shaft 4 by means of which ore material 5 to be ground reaches the interior of the drum 2 . For comminuting the ore material 5 , the loaded drum 2 can be driven in rotation about an axis of rotation 7 by means of a drive 6 , which is designed in the exemplary embodiment as a gearless electric motor.

[0041] A rotation speed sensor 8 for detecting the rotation speed n of the drum 2 is arranged on the drum 2 . The rotational speed sensor 8 is connected to the control and regulation unit 3 . The control and regulation unit 3 includes in particular at least one central processing unit 9 , for example in the form of a microcomputer, microprocessor or microcontroller module, a rotational speed regulator 10 connected to the rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com