Method for producing fungal granular formulation for preventing and treating pest

A technology of granules and granules, applied in the fields of botanical equipment and methods, biocides, biocides, etc., can solve the problem of infestation of target bacteria or weeds affecting the growth of beneficial fungi, difficult to accurately calculate the bacterial content of granules, Environmental microbial contamination and other problems, to achieve the effect of maintaining the vitality of fungi, conducive to infection control, and maintaining biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

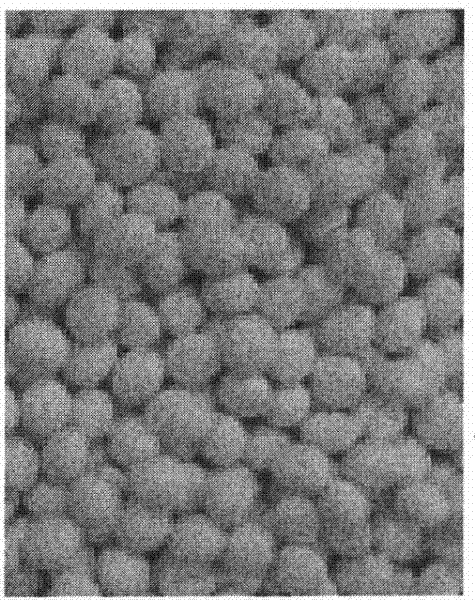

[0029] 1) Cultivate Metarhizium anisopliae from Potato Dextrose Medium Agar to obtain dry and uniform Metarhizium anisopliae conidia powder.

[0030] 2) Take 5 g of spore powder, 85 g of diatomaceous earth, and 10 g of corn flour respectively, and premix them uniformly to form mixture I;

[0031] 3) Add mixture I to 400mL 2% (w:v) sodium alginate aqueous solution, mix well to form mixture II;

[0032]4) Add the mixture II dropwise into 0.25M calcium chloride aqueous solution with a syringe, let it stand for 15 minutes for curing reaction, and shake slowly several times occasionally;

[0033] 5) Remove the particles and transfer them to an aqueous solution containing 2% (w: v) sodium alginate and 6% (w: v) polyvinyl alcohol, and then transfer them to a solution containing 0.25M calcium chloride and saturated boric acid after a few minutes. in the mixed aqueous solution, let stand for 5 minutes;

[0034] 6) Remove the granules, rinse them with sterilized water once, then rinse...

Embodiment 2

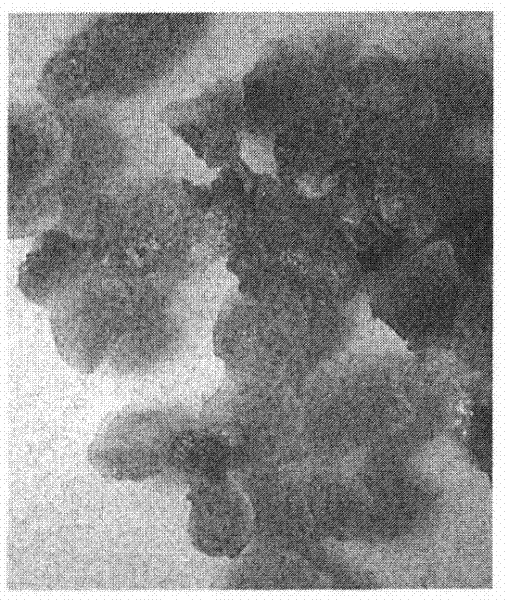

[0036] 1) Cultivating Beauveria bassiana on the wheat bran straw powder medium, and obtaining dry and uniform Beauveria bassiana conidia powder through separation and removal of impurities;

[0037] 2) Weigh 10 g of spore powder, 88 g of attapulgite, and 2 g of rice flour, and pre-mix evenly to form mixture I;

[0038] 3) Add mixture I to 400mL of 1% (w:v) sodium alginate aqueous solution, and mix well to form mixture II;

[0039] 4) Add the mixture II dropwise into 0.28M calcium chloride aqueous solution with a funnel with a controlled dropper, let it stand for 20 minutes for the curing reaction, and shake it gently several times occasionally;

[0040] 5) Remove the particles and transfer them to an aqueous solution containing 1% (w: v) sodium alginate and 5% (w: v) polyvinyl alcohol, and then transfer them to a solution containing 0.28M calcium chloride and saturated boric acid after a few minutes. in the mixed aqueous solution, let stand for 5 minutes;

[0041] 6) Remove ...

Embodiment 3

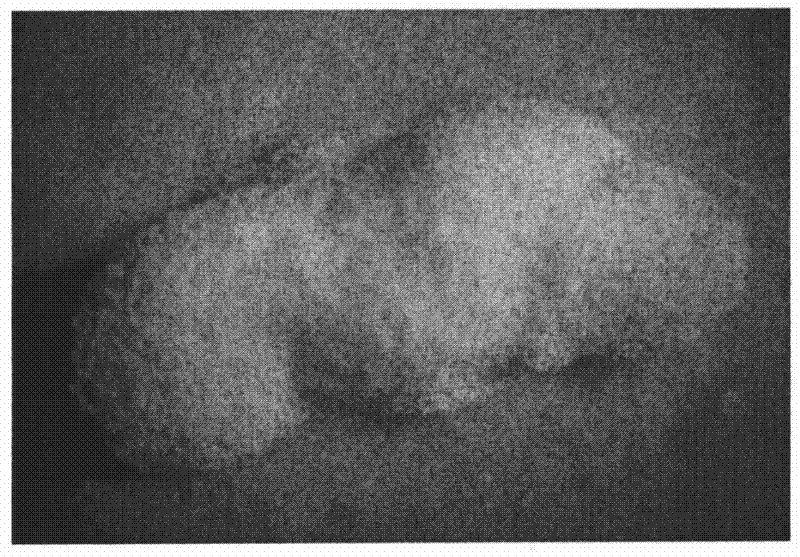

[0043] 1) Cultivate Verticillium lecanii on the rice grain medium, and obtain dry and uniform conidia powder of Verticillium lecanii through separation and removal of impurities;

[0044] 2) Weigh 10 g of spore powder, 80 g of attapulgite, and 10 g of soluble starch, and premix evenly to form mixture I;

[0045] 3) Add mixture I to 250mL of 1% (w:v) sodium alginate aqueous solution, mix well to form mixture II;

[0046] 4) Add the mixture II dropwise to 0.25M calcium chloride aqueous solution with a pressurizable dropper, let it stand for 30 minutes for curing reaction, and shake it gently several times occasionally;

[0047] 5) Remove the particles and transfer them to an aqueous solution containing 1.5% (w: v) sodium alginate and 3.5% (w: v) polyvinyl alcohol, and then transfer them to a solution containing 0.25M calcium chloride and saturated boric acid after a few minutes. in the mixed aqueous solution, let stand for 10 minutes;

[0048] 6) Remove the granules, rinse the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com