Split capsule type cupping device

A split and capsule technology, applied in the direction of suction equipment, etc., can solve the problems of inconvenience, need for electric energy, and inability to move with you, and achieve the effect of simple and convenient operation, compact structure, and scientific design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

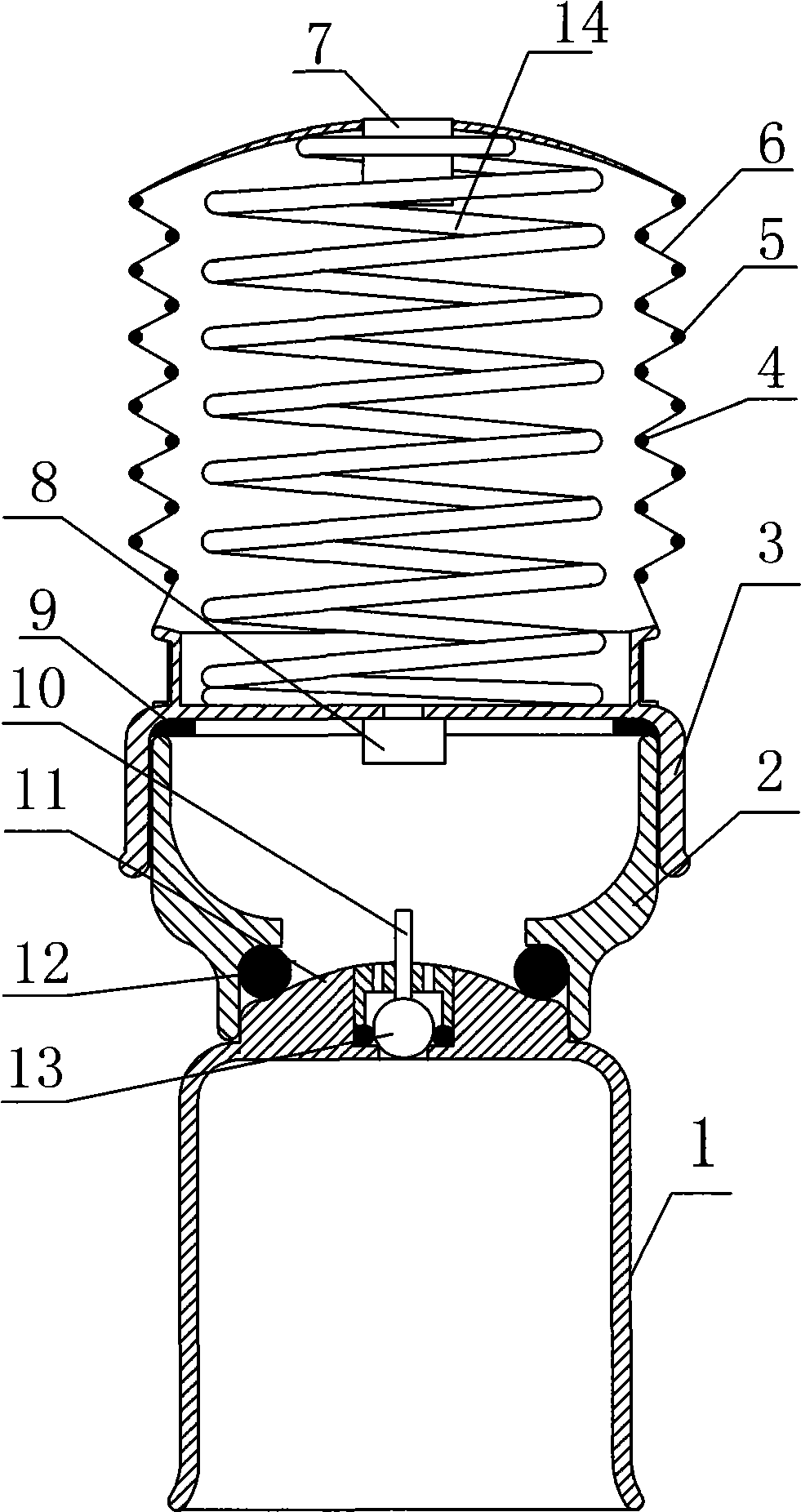

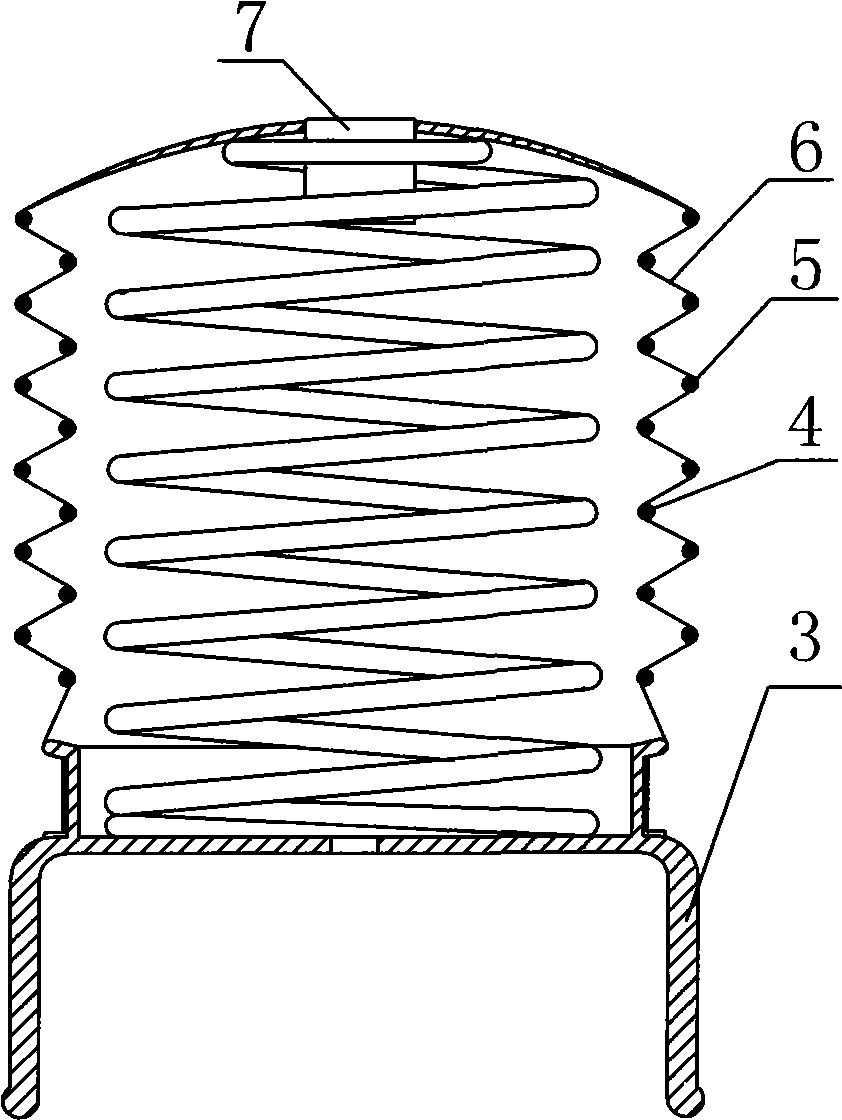

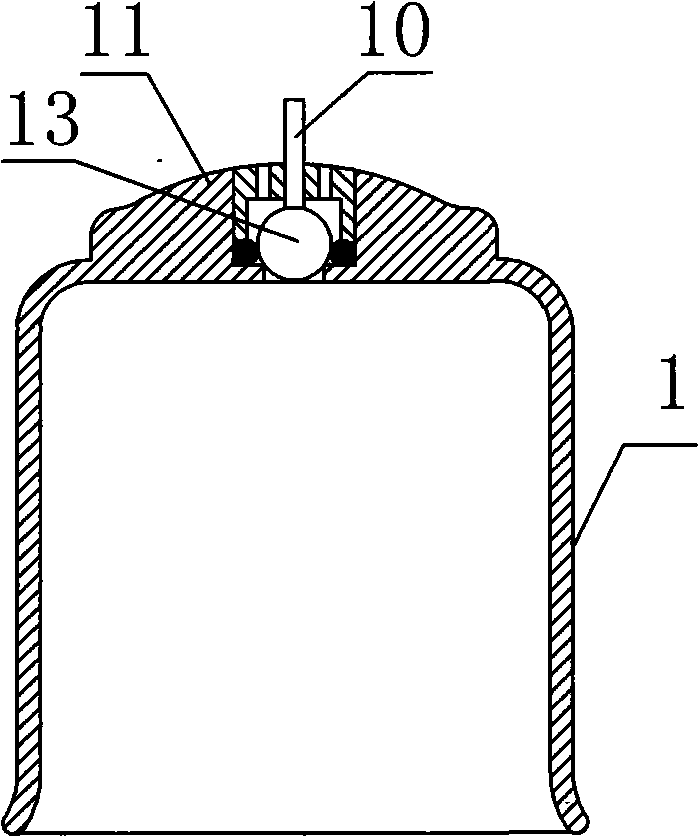

[0016] Embodiment: As shown in the accompanying drawings, the cupping device of the present invention is very simple and convenient to manufacture. Each component is processed by injection molding as shown in the accompanying drawings, and then assembled together. The bellows can be made of rubber or plastic film or rubberized fiber cloth. The manufacturing process is a known technology.

[0017] The use of the cupping device of the present invention is more simple and convenient. When in use, the opening of the split tank is buckled on the skin of the acupuncture point, and the boss on the top of the split tube is plugged together with the socket at the lower end of the bellows type negative pressure pump. , the spring in the bellows is compressed, the gas in the bellows is discharged from the one-way valve, and then released, the one-way valve is closed, the spring expands and the bellows expands, the volume inside the bellows becomes larger, generating negative pressure, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com