Explosion welding technology for machining and manufacturing continuous casting roller

A technology for processing and manufacturing continuous casting rolls, which is applied in the field of continuous casting roll explosive welding processing and manufacturing technology, can solve the problems of complicated surfacing welding procedures, low production efficiency, and non-environmental quality, and achieve reduced physical hazards, high production efficiency, and energy saving The effect of precious metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

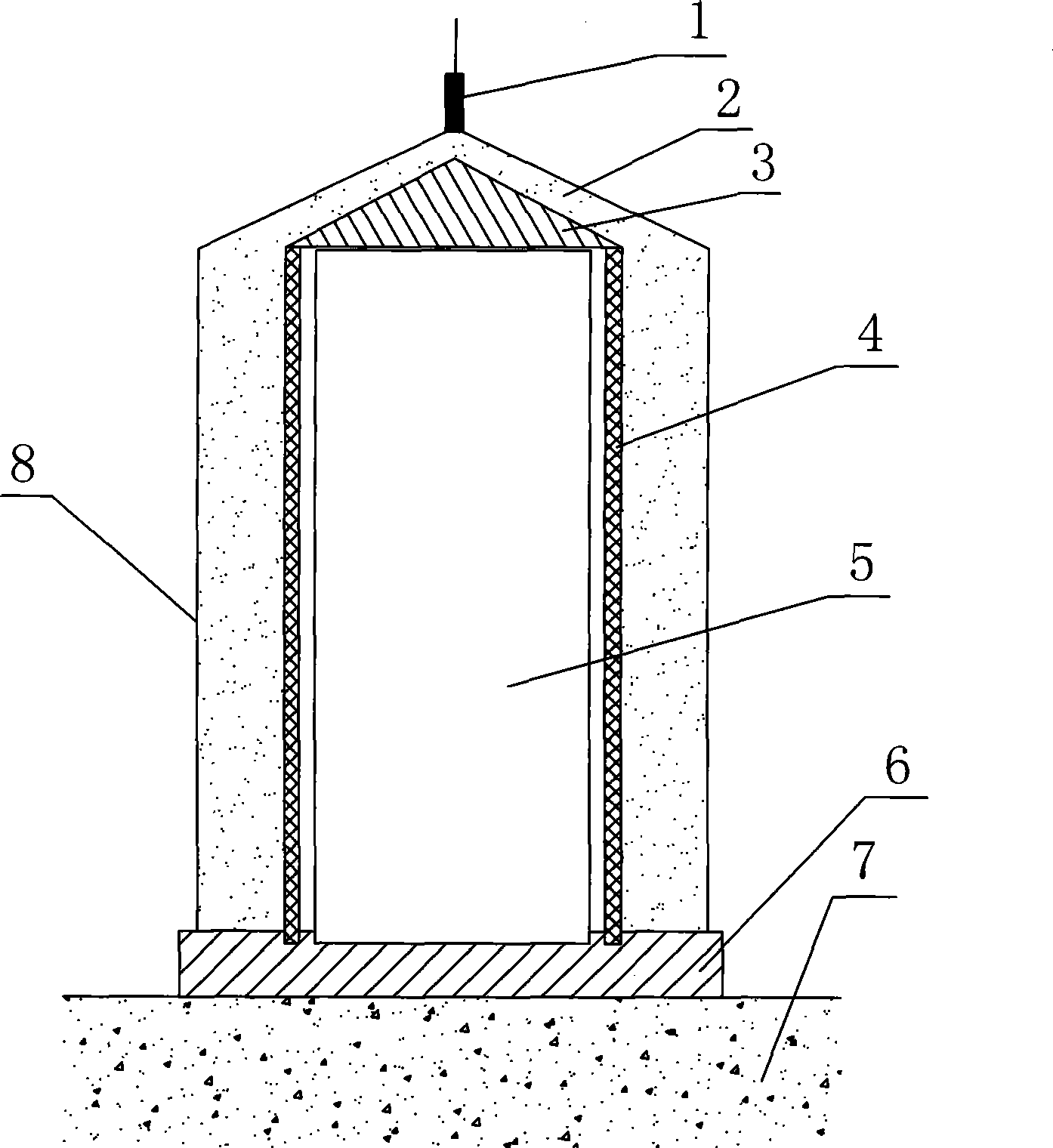

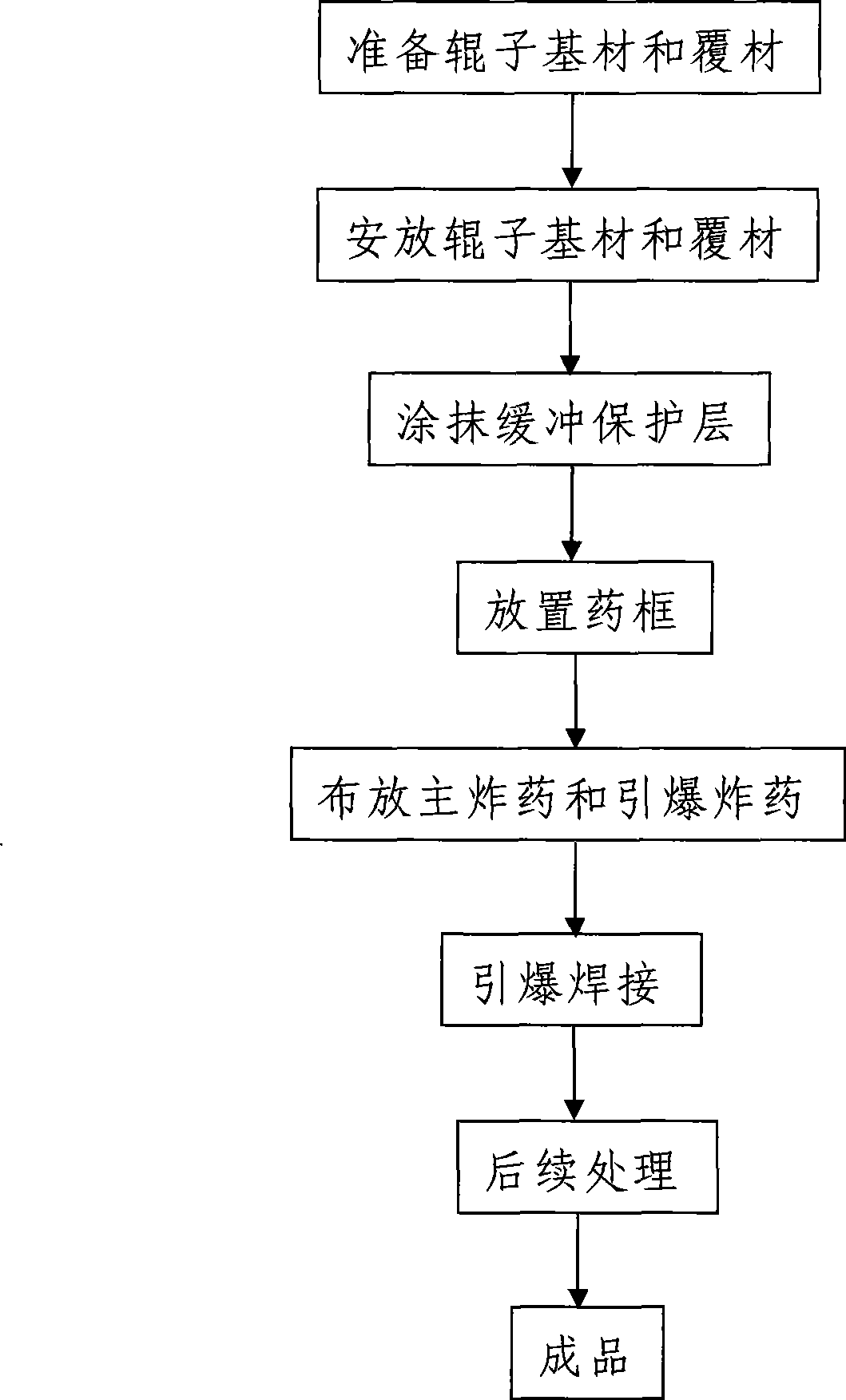

[0032] Such as figure 1 , figure 2 Shown, continuous casting roll explosive welding manufacturing process of the present invention comprises the following steps:

[0033] Step 1. Prepare the roller base material 5 and the covering material 4:

[0034] Process and prepare the roller base material 5 and the covering material according to the conventional mechanical processing technology. The formed roller base material 5 is a solid or hollow cylindrical base material, and the formed covering material 4 is a height higher than the roller base material. 5 round pipe with uniform wall thickness. The material of the cladding material 4 is the same as that of the welding wire used in the conventional continuous casting roll surfacing process. The roughness Ra of the outer surface of the roller substrate 5 and the inner surface of the cladding 4 are both less than 6.3 μm. The inner diameter of the cover material 4 is larger than the outer diameter of the roll base material 5 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com