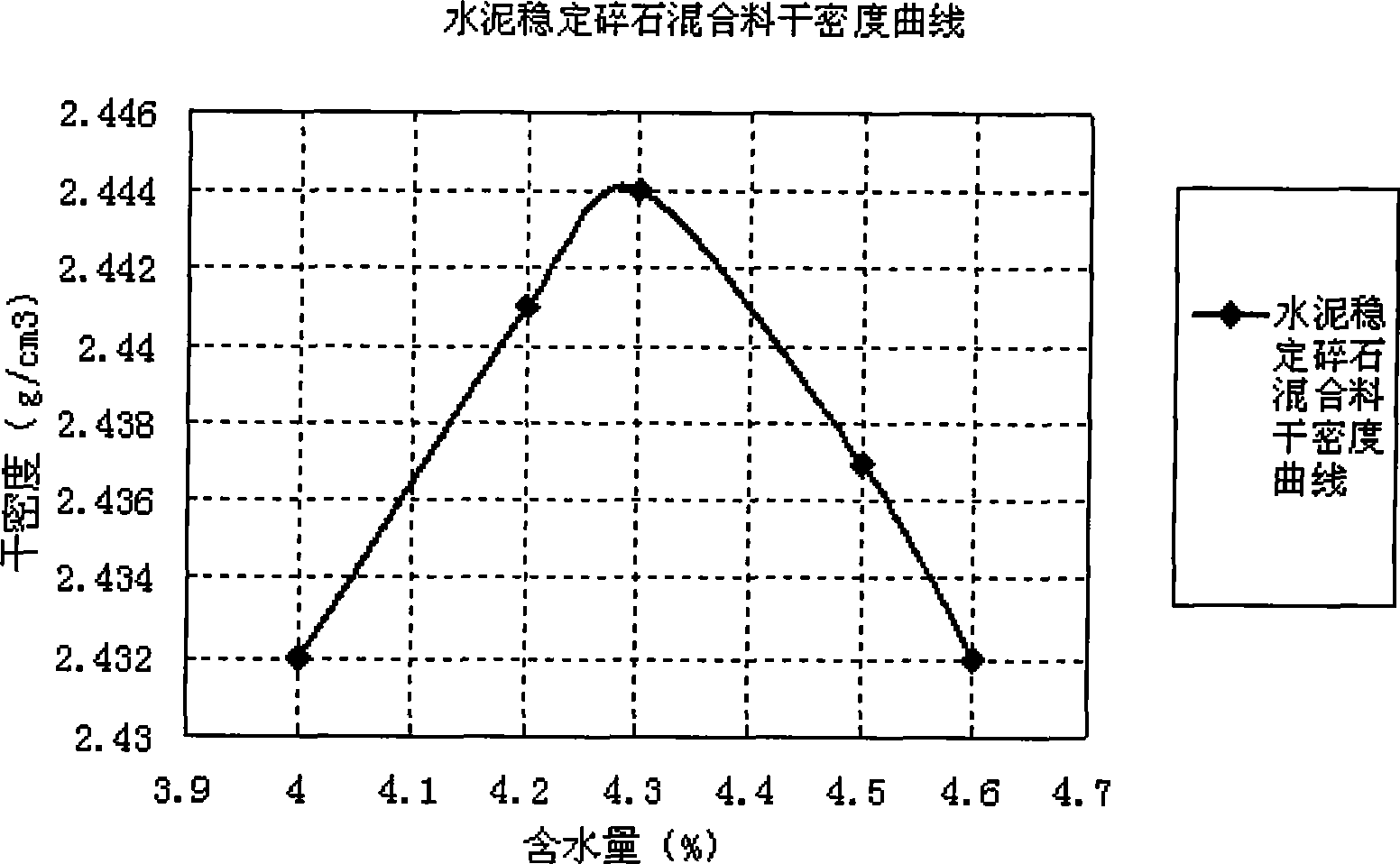

Experiment method for measuring maximum dry density of highroad base material

A technology of maximum dry density and road base, which is applied in the test of infrastructure, infrastructure engineering, construction, etc., can solve the problems of poor test reproducibility, complicated operation, and long time consumption, and achieve stable test results, improved work efficiency, The effect of simplifying the charging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

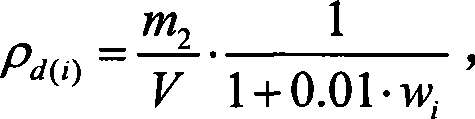

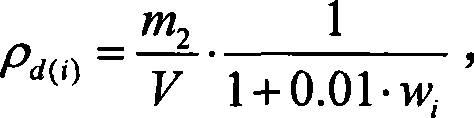

Method used

Image

Examples

Embodiment Construction

[0023] (1) Place the test sample (limestone) in an oven, adjust the temperature to 105°C, and dry for 5 hours. Take 5 samples from the dried samples, each with a mass of 5000g.

[0024] (2) Take a portion of the sample and spread it on a metal plate, add 200g of cement (4.0% cement dosage), and mix evenly. Spray 218g (mixing water content is 4.2%) water evenly on the mixture and mix evenly.

[0025] (3) Put the mixed material mixed evenly with water into the test mold of diameter×height=150mm×150mm, before loading, weigh the mass of the test mold to be 15231g. Put the mixture into the test mold as much as possible according to the quartering method, weigh 20641g, subtract the mass of the test mold, and calculate the actual charging mass m 1(1) = 5410 g. Fix the test mold with the mixture on the vibrator, and set the parameters of the vibrator as vibration frequency 30Hz, excitation force 7.6kN, nominal amplitude 1.4mm, working weight 3.0kN, boarding system 1.2kN, dismountin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com