Vapor-liquid separation method for vertical condenser and condenser

A technology of vapor-liquid separation and condenser, which is applied in steam/steam condensers, heat exchanger shells, lighting and heating equipment, etc. It can solve the limitation of condensate flow range, insufficient suction force, and affect the effect of liquid separation, etc. problem, to achieve the effect of ingenious structural design and guaranteed steam resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

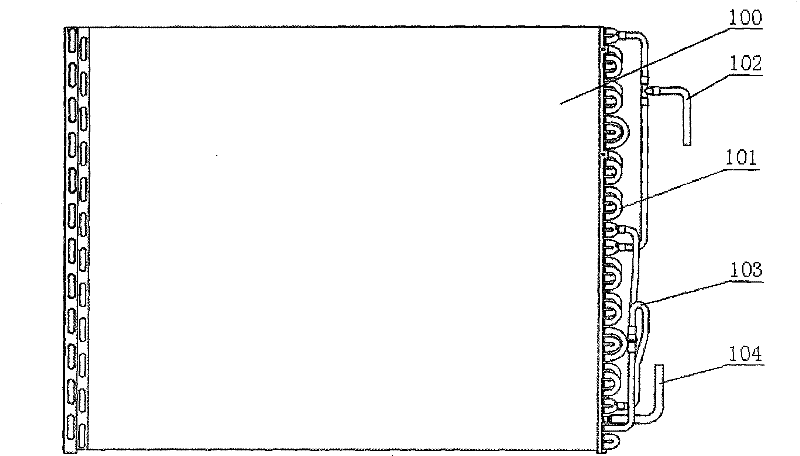

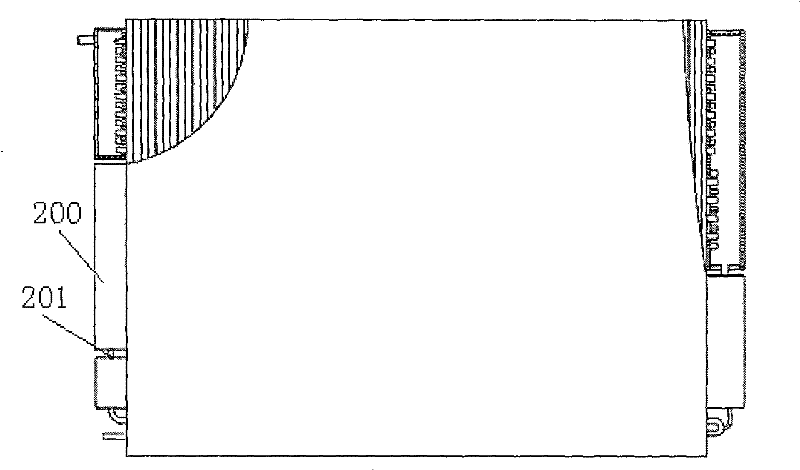

[0042] Embodiment 1: A kind of vertical tube condenser unit in series

[0043] As shown in Figure 5, this embodiment includes a heat exchange unit module A, the heat exchange unit module A includes a plurality of sets of heat exchange tubes 1 arranged vertically in descending order from top to bottom (or from bottom to top), the heat exchange tubes 1 is provided with fins 11 outside. Each group of heat exchange tubes 1 is connected through multi-stage headers 2 installed at both ends, and the number of stages of heat exchange tubes 1 and headers 2 can be adjusted as required. A steam inlet 21 is arranged on the first cascade box 2 (the uppermost header in the figure, but not limited to this). The first cascade box 2 communicates with the second cascade box 2 through the first group of heat exchange tubes 1, and the second cascade box 2 communicates with the third cascade box 2 through the second group of heat exchange tubes 1, ... until finally First header 2. Each set of h...

Embodiment 2

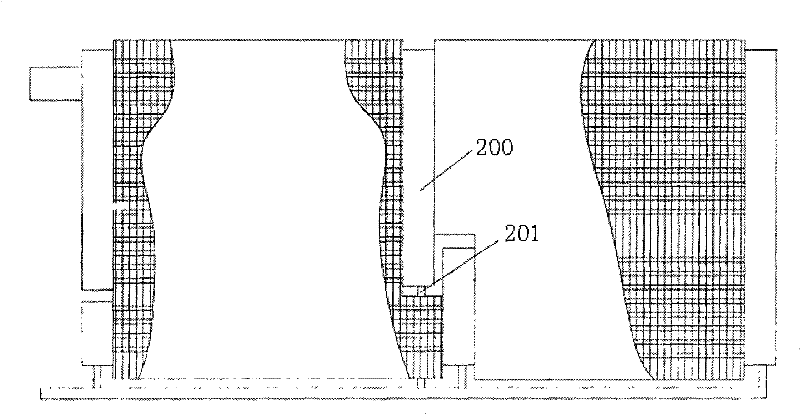

[0046] The leaking liquid vapor arresting device 3 in this embodiment includes a base plate 31 having the same cross-sectional size as the liquid collecting guide pipe 2, and the center of the base plate 31 has a main hole 32 with an equivalent diameter of 2 to 5 mm and the same aperture, surrounding the main hole 32 is evenly arranged with a circle of auxiliary holes 33 with an equivalent diameter less than 2 mm and the same equivalent aperture. When the condensate produced in the heat exchange tube 1 upstream of the condenser is less, the liquid separated from the header 2 will form a layer of liquid film on the surface of the main hole 32 and the auxiliary hole 33 of the substrate 31, preventing liquid and gas from flowing The main orifice 32 and the auxiliary orifice 33 flow out. When the liquid volume increases slightly, the main hole 32 with a larger aperture will seep first, which is equivalent to the single drain pipe in the prior art. When the amount of separated liq...

Embodiment 3

[0048] Such as Figure 8 , Figure 9 As shown, the size ranges of the main hole 32 and the auxiliary hole 33 in this embodiment are similar to that of Embodiment 1, the difference is that the main hole 32 and the auxiliary hole 33 are frustum holes with variable equivalent apertures, and the equivalent apertures can be larger at the top and lower at the bottom. Small; it can also be small at the top and large at the bottom, and it can also be in any form of variable cross-sectional area. This structure enables both the main hole 32 and the auxiliary hole 33 to carry a certain amount of condensate. When the amount of condensate is relatively low, the main hole 32 can also ensure continuous drainage and prevent steam from passing through. The presence of condensate in the pores of the auxiliary holes 33 can improve its steam resistance ability and prevent steam from passing through, and can also improve the steam resistance ability and accelerate liquid discharge according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com