Manufacturing method for temperature adaptive reflecting surface regulating component

A technology for adjusting components and manufacturing methods, applied to electrical components, antennas, etc., can solve problems such as deterioration of reflective surface accuracy σ, different linear expansion coefficients of materials, and uncoordinated deformation, and achieve low price and cost, reduced deterioration, and high performance. Stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

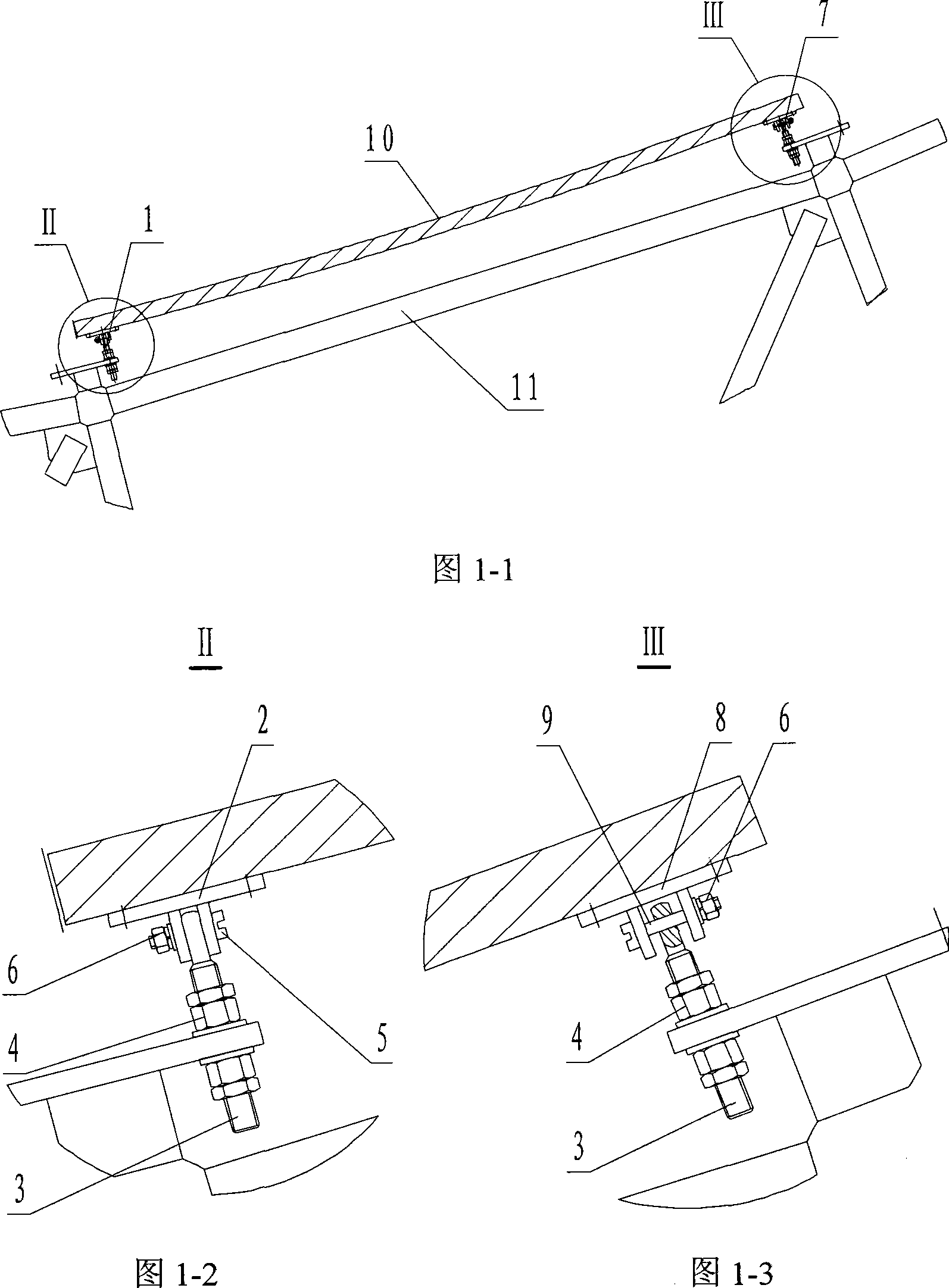

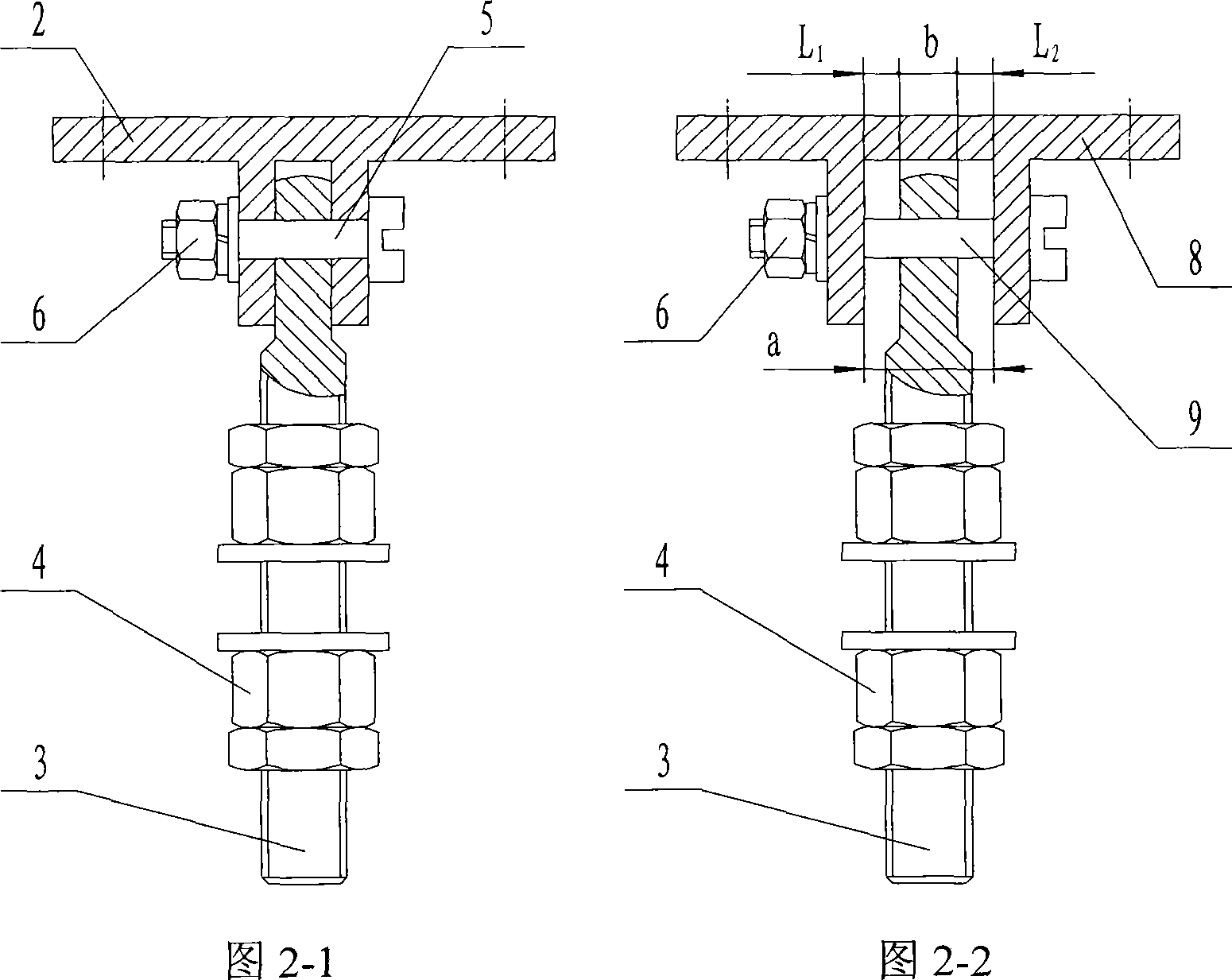

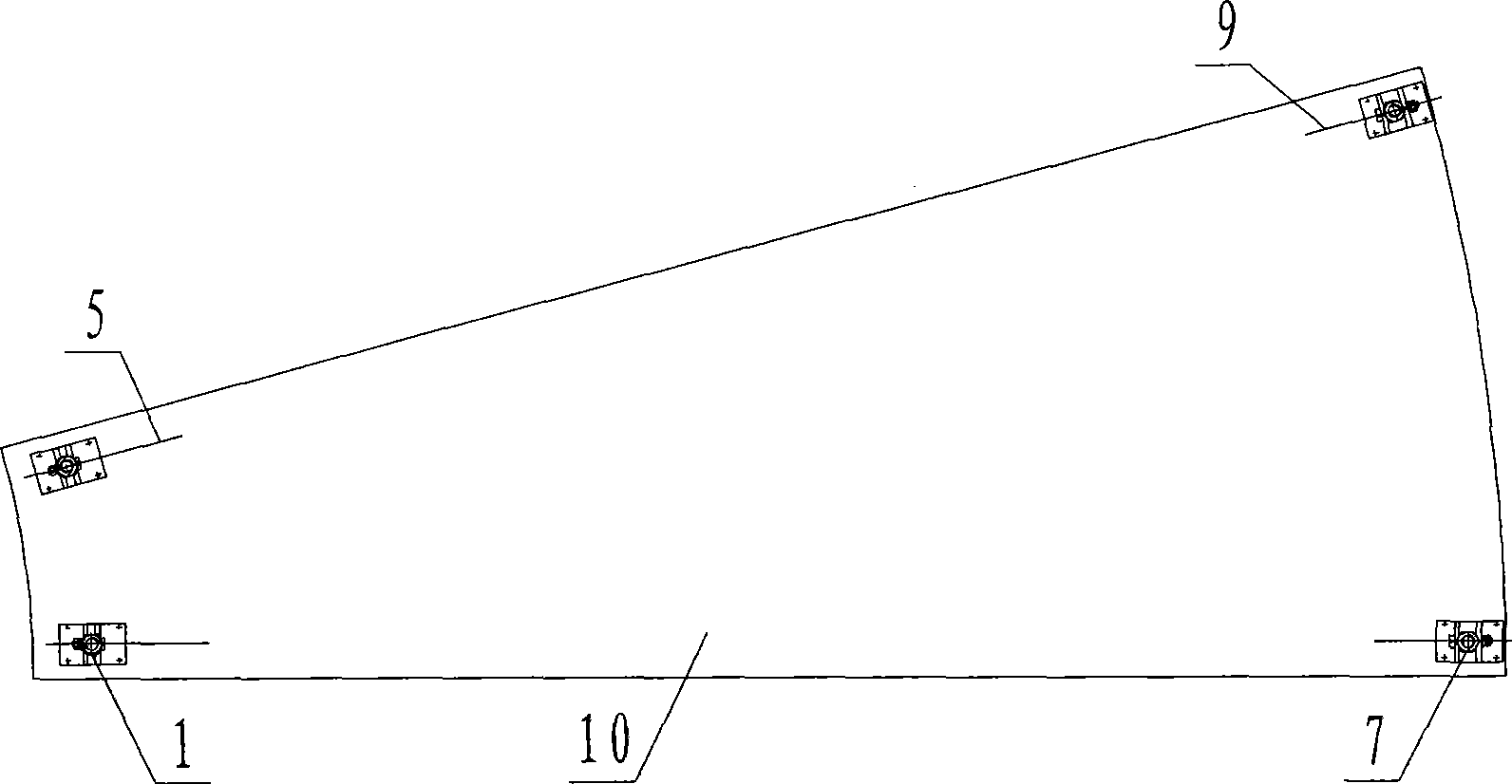

[0038] The best embodiment of the present invention is as figure 1 as shown, figure 1 It is a schematic diagram of the installation structure of the best embodiment of the present invention. It includes single degree of freedom adjustment part 1, single degree of freedom adjustment seat 2, adjustment screw rod 3, large standard part 4, single degree of freedom shaft 5, small standard part 6, double degree of freedom adjustment part 7, double degree of freedom adjustment seat 8, A dual-degree-of-freedom axis 9 , a reflector unit 10 , and an antenna back frame 11 .

[0039] The present invention adopts the principle of automatic adjustment of temperature difference and thermal deformation between different materials by combining single-degree-of-freedom adjustment parts and double-degree-of-freedom adjustment parts. The reflective surface is displaced in the radial direction to adapt to the temperature difference deformation, and the combination of single and double degree of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com