Frame structure for a device and/or a part in a fibre web manufacturing line

A fiber web and production line technology, applied in the direction of winding strips, transportation and packaging, thin material handling, etc., to achieve the effects of short downtime, reduced times, and reduced installation workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

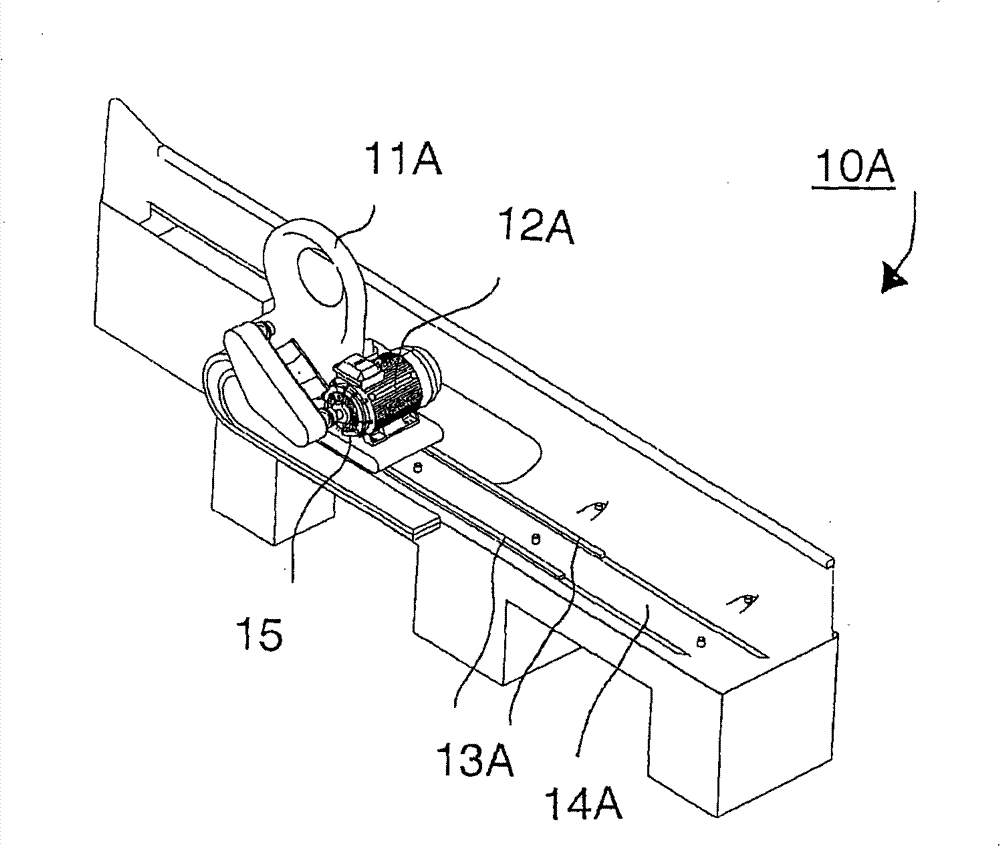

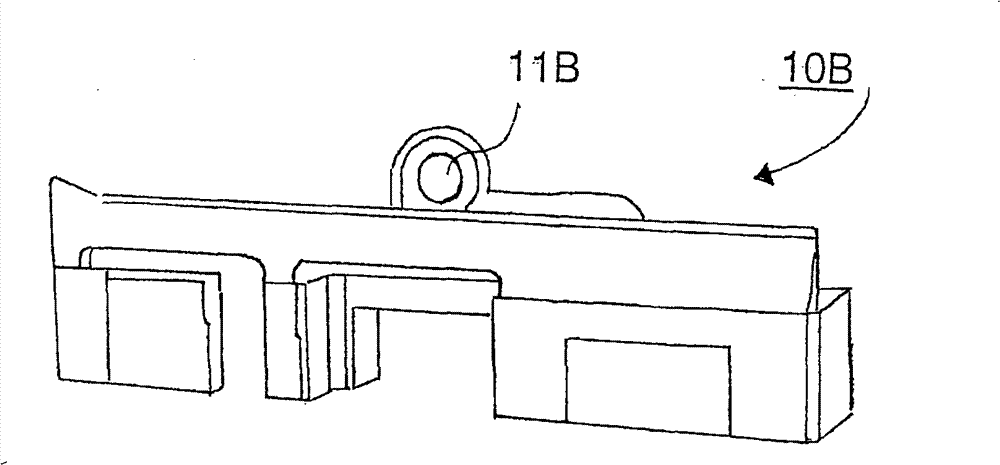

[0023] Figure 1A-1B The unit frame parts 10A, 10B are schematically shown on both sides of a device in a fiber web production line, a winder in the figure. The unit rack according to the present invention comprises at least two unit rack parts 10A, 10B, namely the rack part 10B ( Figure 1B ) and the frame part 10A ( Figure 1A ). According to the invention, the unit frame parts 10A, 10B are made of concrete and are formed as a movable whole which is prefabricated and which can be installed as a module at a suitable location in a fiber web plant. The two unit frame parts 10A, 10B comprise coupling means 11A, 11B for coupling the ends of the reels. The driving device 12 and its bed 15 (bed) are arranged in combination with the fixing device 11A on the driving side. As the coiling process proceeds at different stages of the coiling, the reel and the fibers formed around the reel during the reeling process The web roll is moved by said drive means 12 on guide means 13 attach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com