Unit in a forming section of a papermaking machine

一种成型部、造纸机的技术,应用在造纸机、纸机湿部、造纸等方向,能够解决占地面积大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

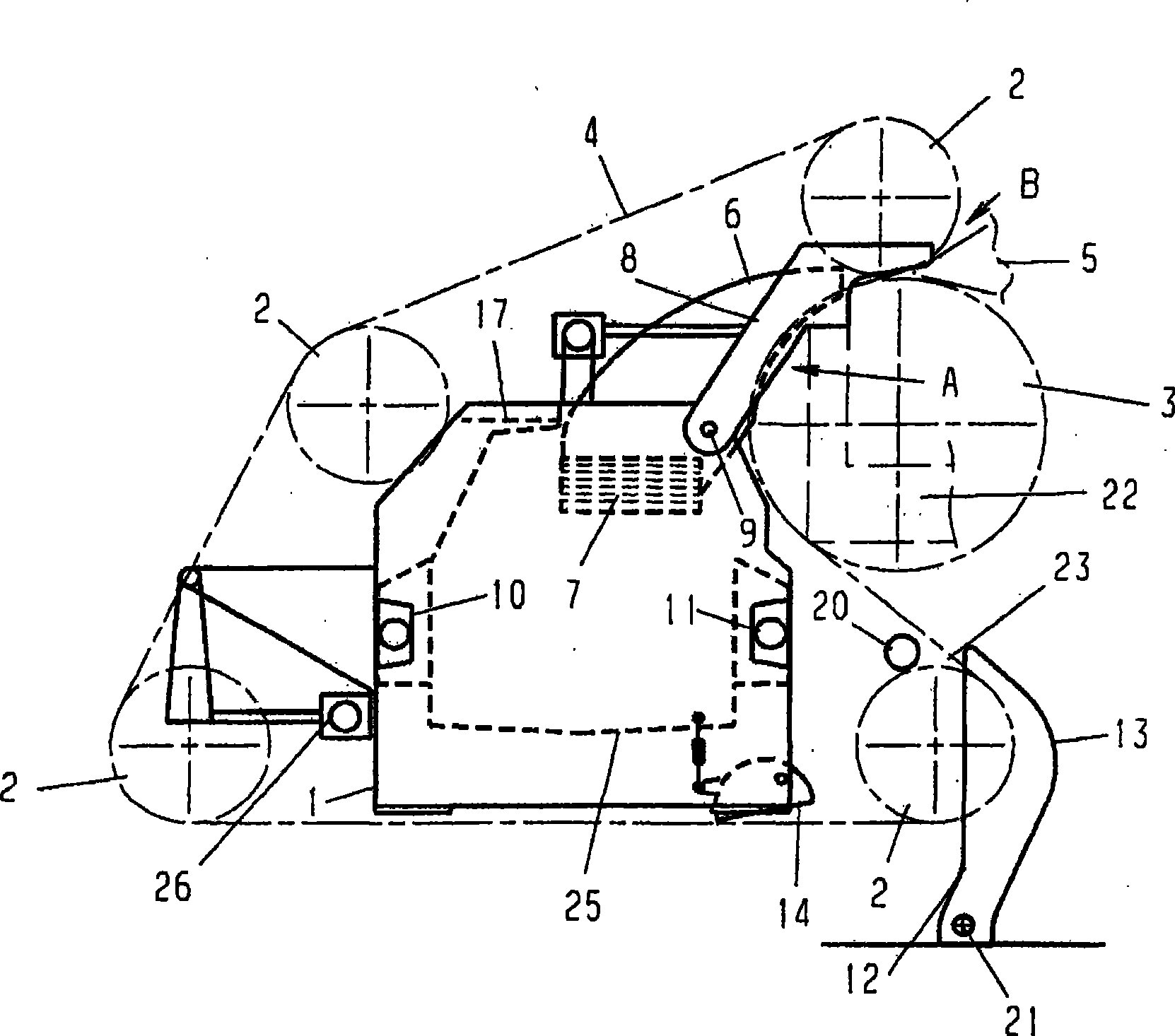

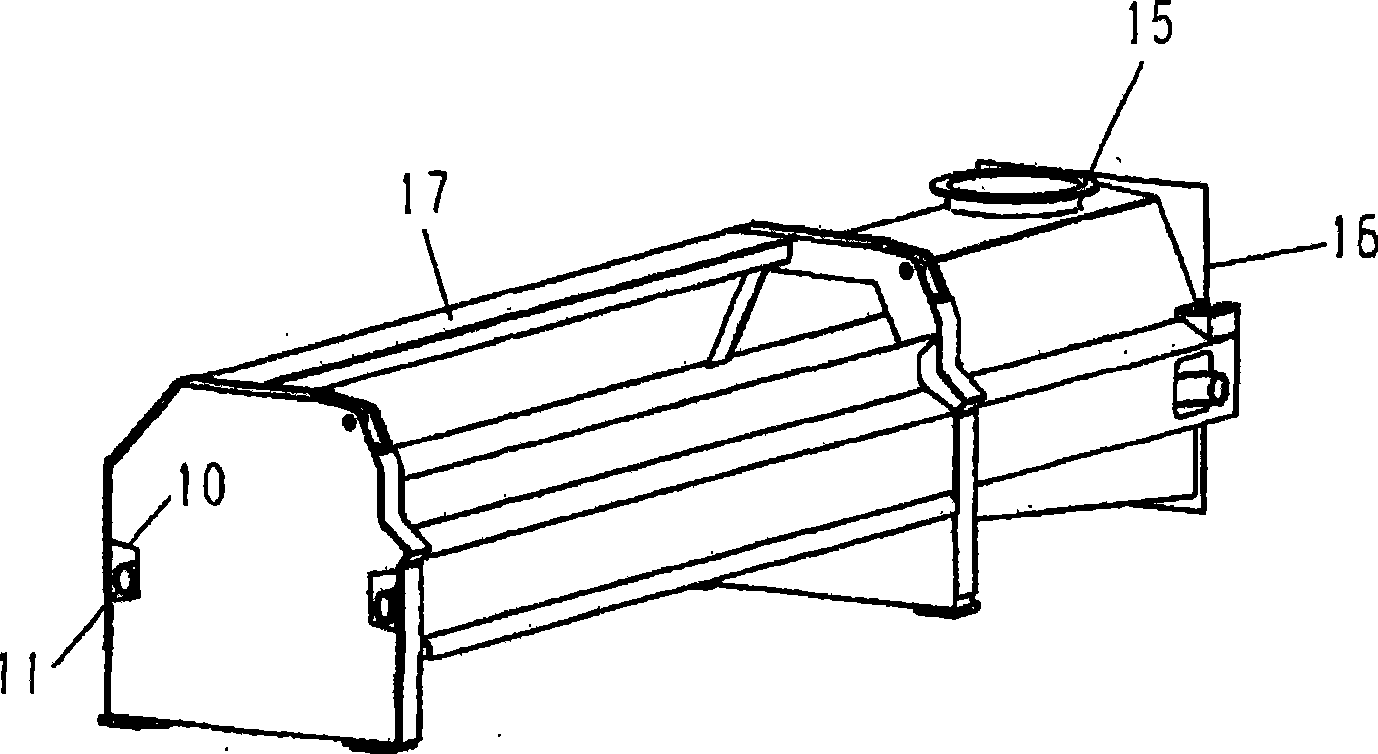

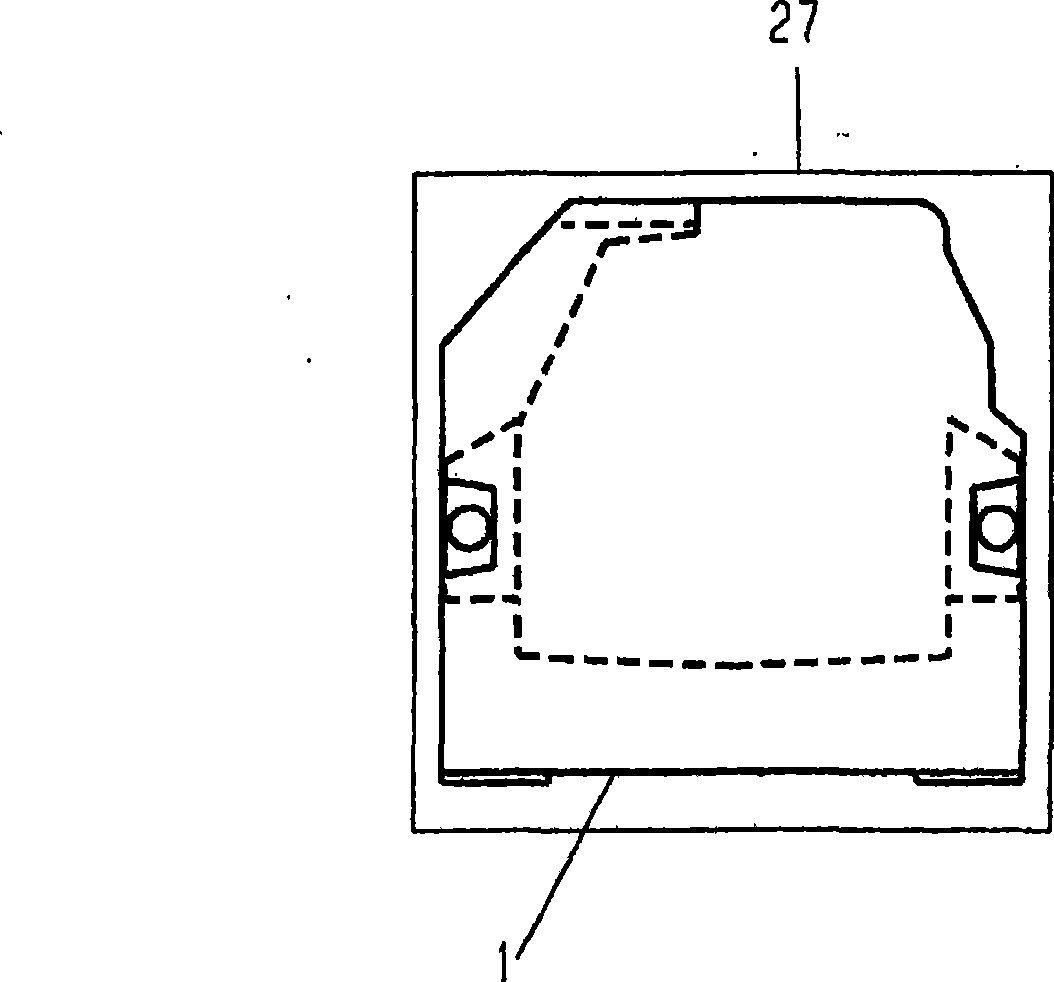

[0023] A compact unit 1 for a crescent former type twin wire forming section in a paper machine such as a tissue paper machine, ie according to the invention and as figure 2 The unit 1 shown is pre-assembled and self-supporting. The unit 1 can be easily installed on the machine room floor after being transported to the site without the need for a special base. Such as figure 1 As shown, the unit 1 includes an integral recovery channel 25 which defines the shape and dimensions of the unit 1 . The unit 1 also has an integrated beam 10 reserved for pipeline access, in which all the transverse ducts 11 necessary for the operation of the machine will be arranged, and also has such as figure 1 and Figure 7 Integral lateral passages 13, 17 for service personnel are shown. A plurality of rollers 2 are mounted in a known manner on the compact unit 1, and said rollers are provided with roller telescoping devices 26 for possible adjustment of the position of the guide rollers 2 or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com