Wood floor superficial makings treatment method and device

A surface texture and processing device technology, which is applied to wood processing equipment, sawing equipment, circular saws, etc., can solve the problems of high mold processing costs, high production costs, and large equipment investment, and achieve low production costs, small investment, and Simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A wood floor surface texture treatment method and a treatment device used in the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but they are not used as a basis for any limitation of the present invention.

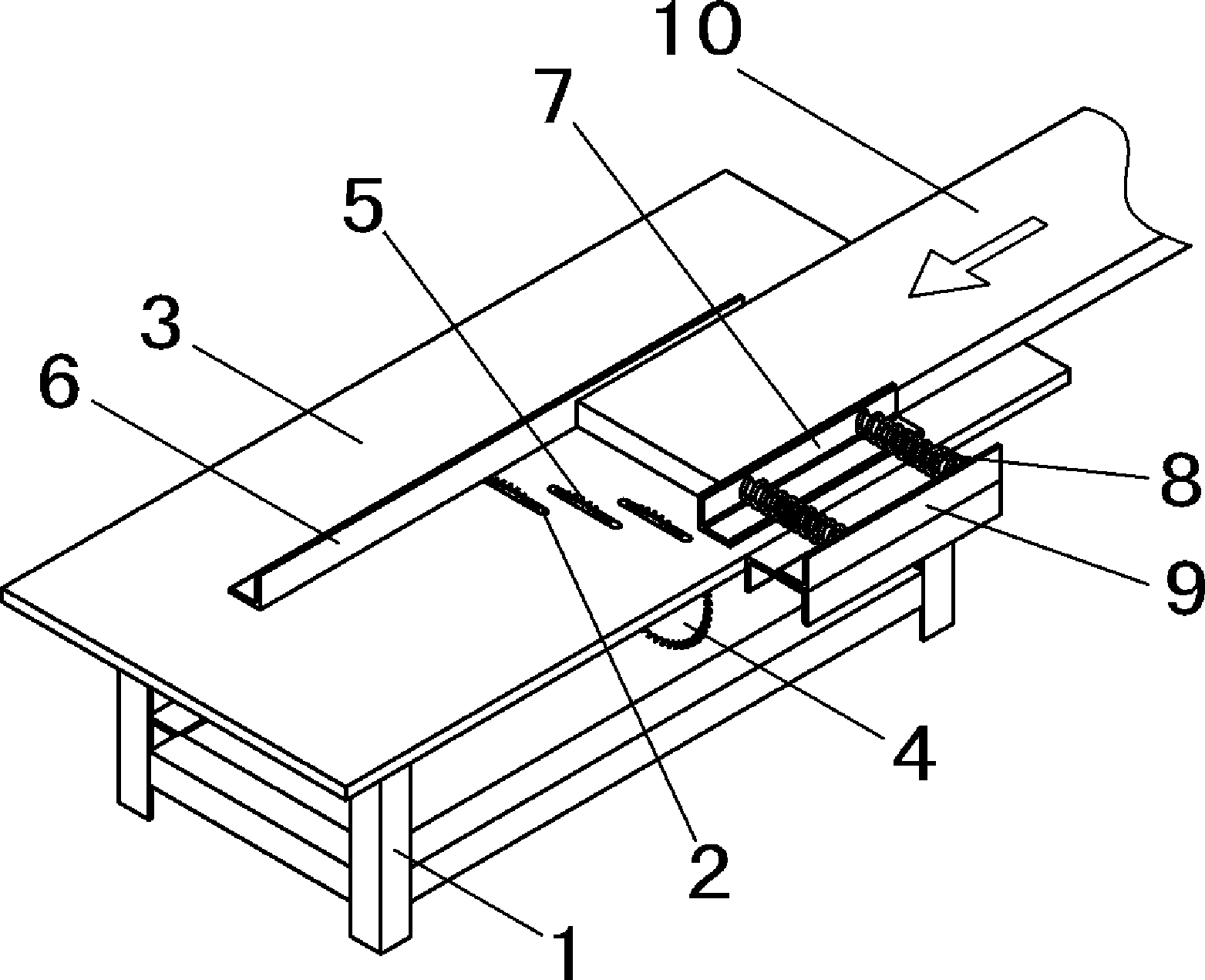

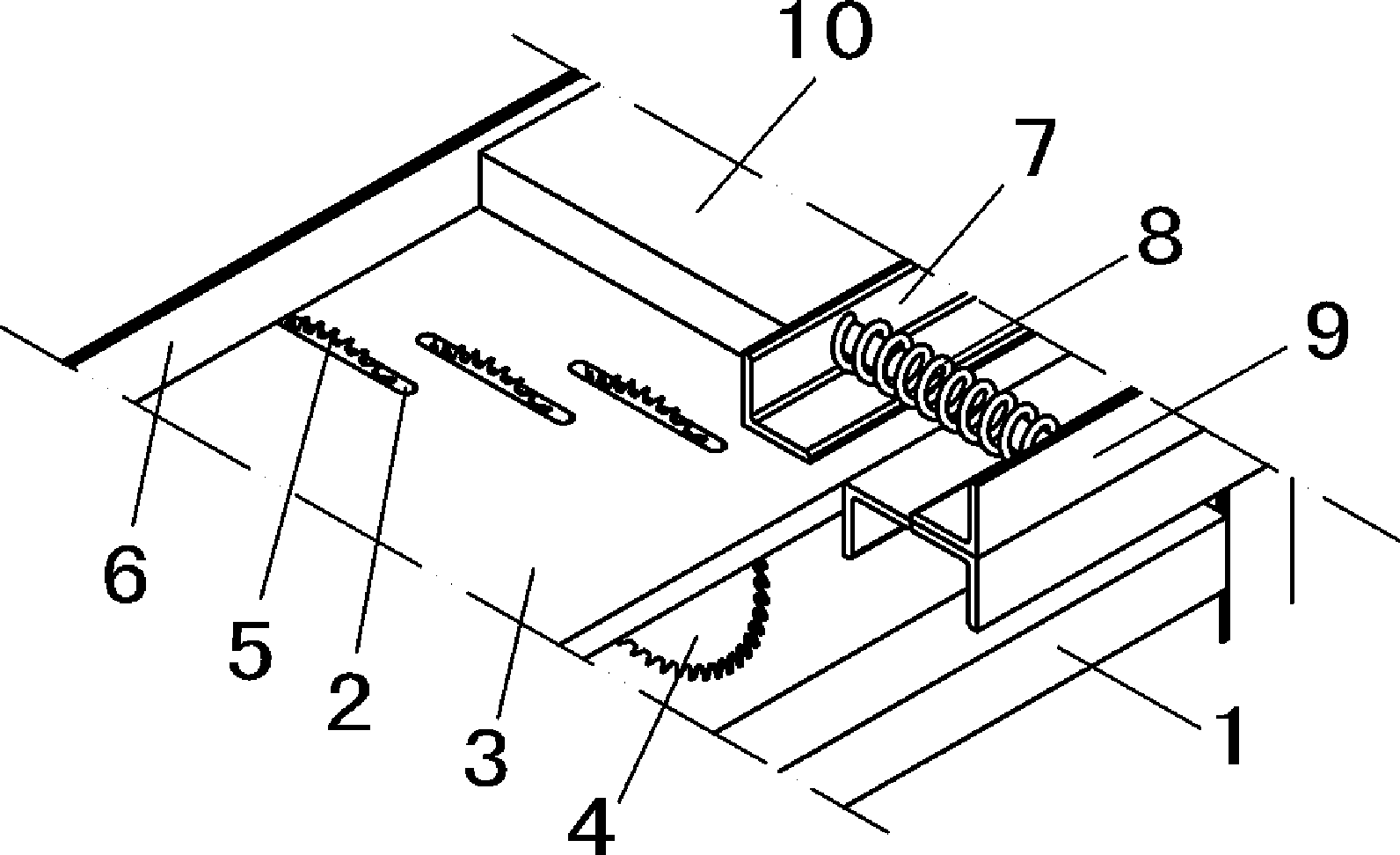

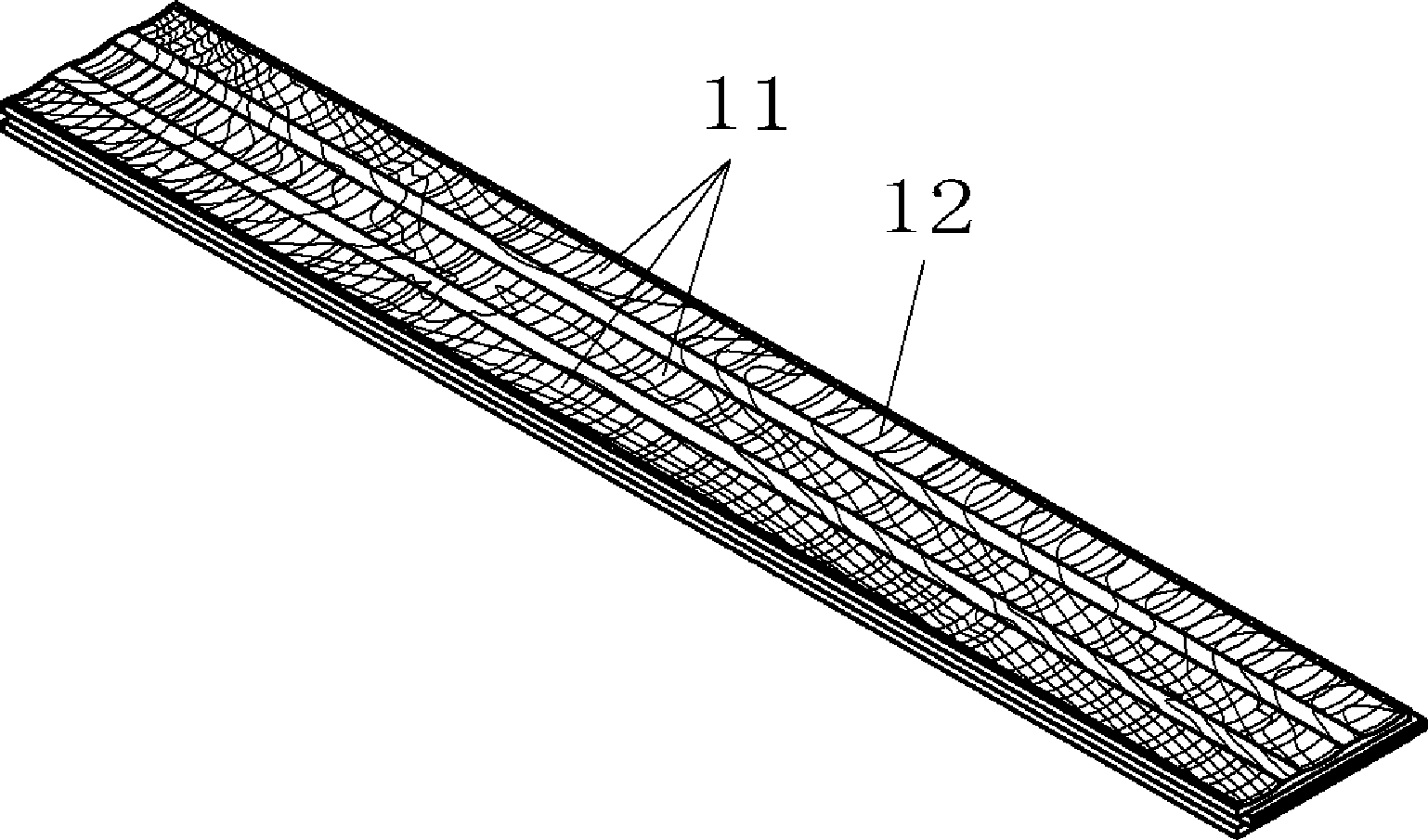

[0019] Example. Wooden floor surface texture treatment methods, such as figure 1 and figure 2 shown. The method is to texturize the wooden floor surface by means of a circular saw blade. By changing the sawtooth shape of the circular saw blades, the number of circular saw blades, the distance between the circular saw blades, the angle between the circular saw blades and the wooden floor, the moving speed of the wooden floor or the height of the circular saw blades , or by changing their combination, different textures are processed on the surface of the wooden floor to form a patterned floor.

[0020] The processing device used for the wood floor surface texture processing method includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com