Support table body with heater in crystal growth furnace

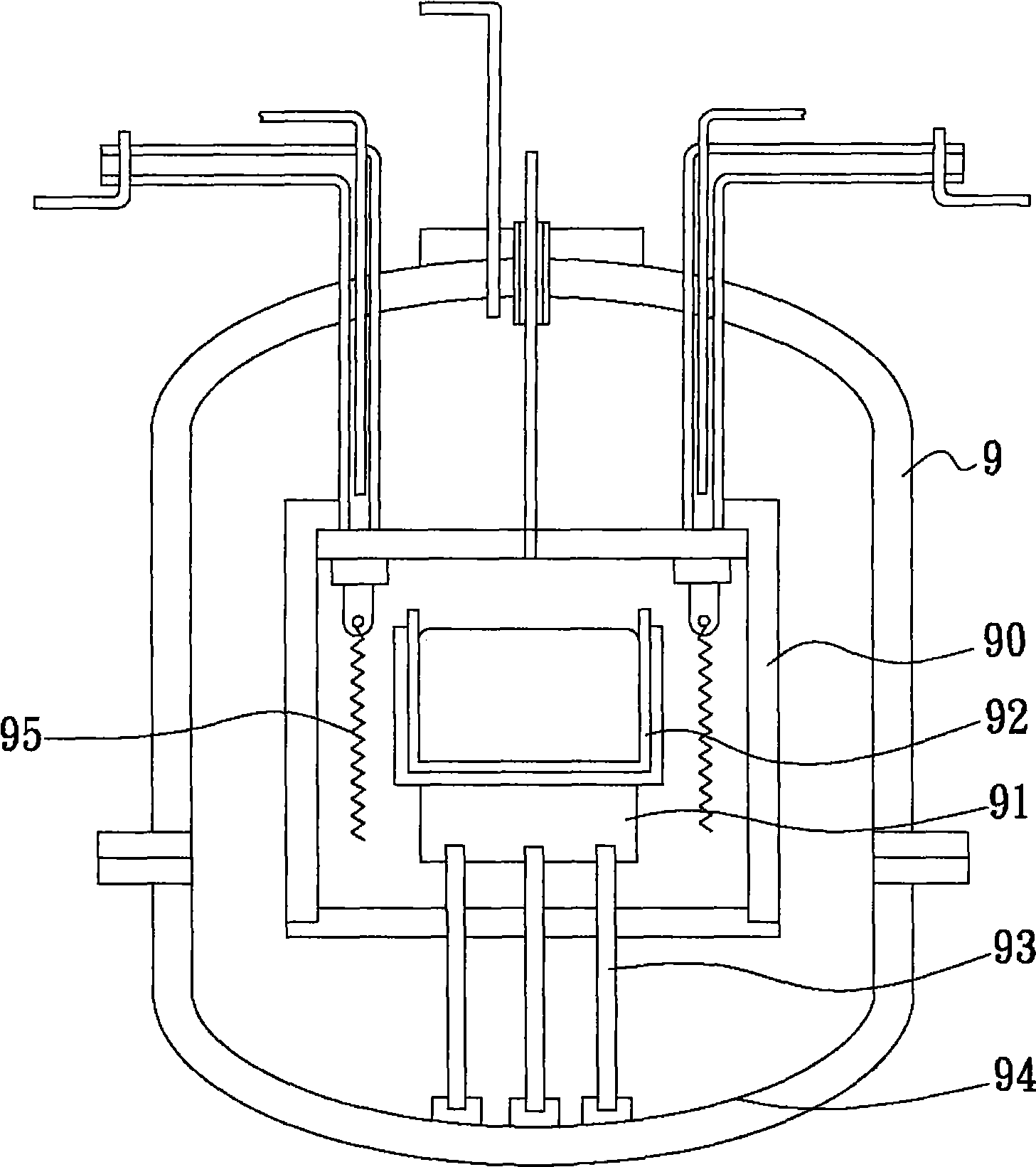

A crystal growth furnace and heater technology, applied in lighting and heating equipment, furnaces, crucible furnaces, etc., can solve problems such as uneven cooling, difficult heat dissipation of the table 91, and poor product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

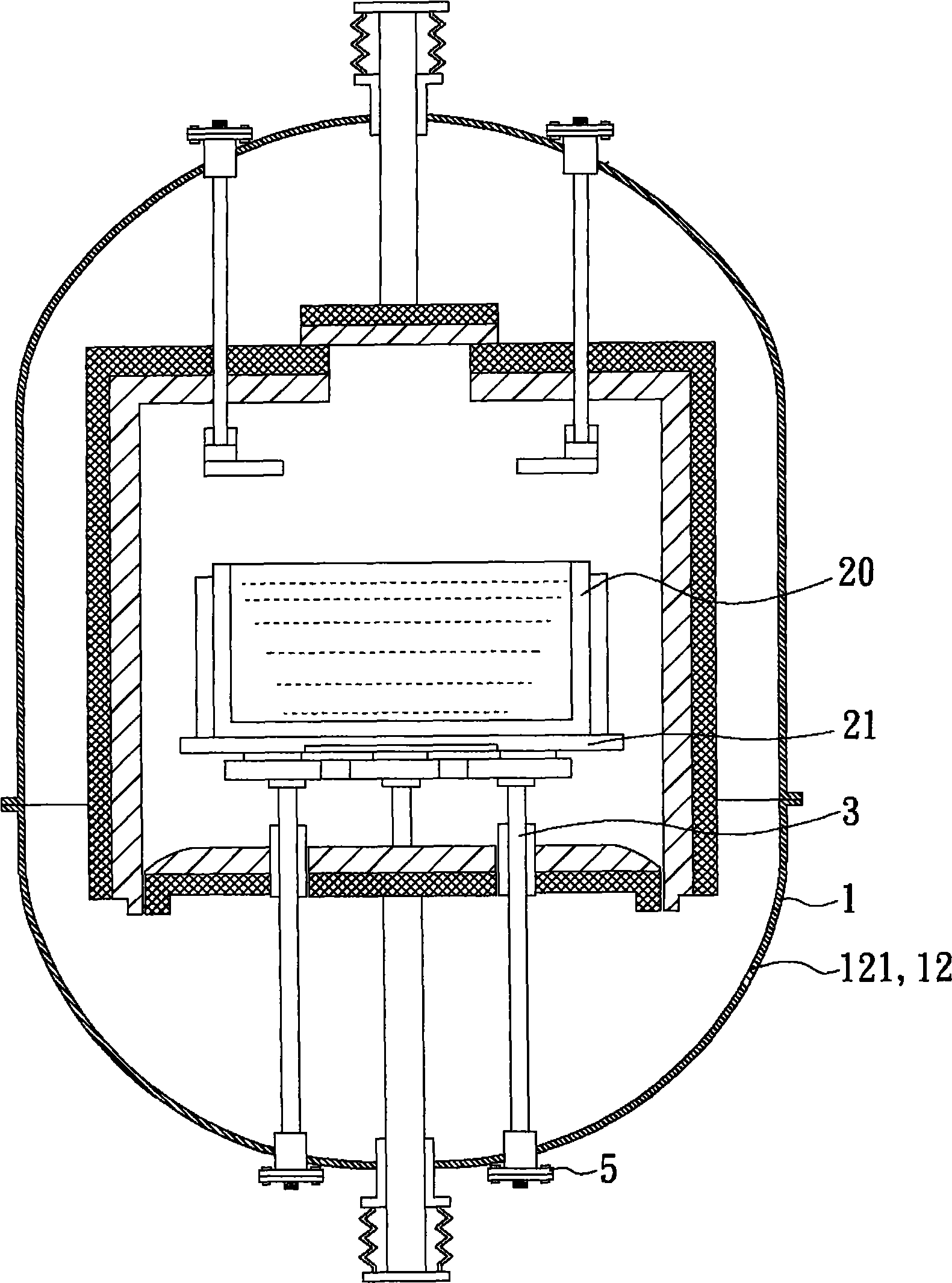

[0058] In the crystal growth furnace of the present invention, there is a support table body of a heater, including a table board and more than four support columns, and the table board is supported and fixed in the furnace wall of its furnace bottom cover of a crystal growth furnace through the support columns. .

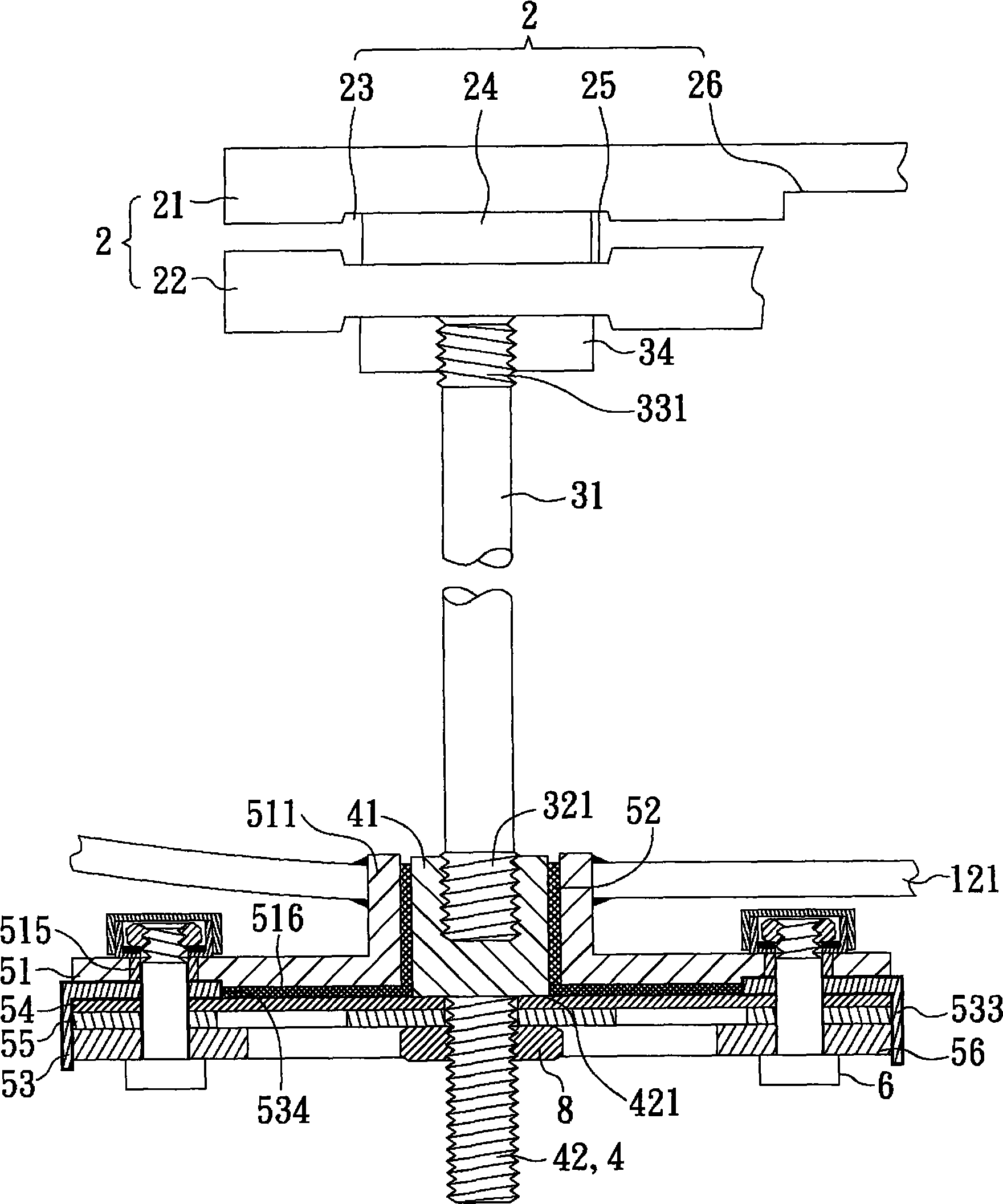

[0059] The supporting table body includes a plurality of electric heaters, which are respectively arranged under the table board. Wherein, each supporting column includes a graphite electrode column, a metal electrode column, a fixing seat, a plurality of fixing bolts, and a locking nut.

[0060] The graphite electrode support includes a bottom end and a top end, the bottom end is provided with an external thread, and the top end is supported against the bottom of two ends of one of the plurality of electric heaters and is electrically connected with each other. The metal electrode column includes a nut base and an outer screw rod. One end of the nut base is reces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com