Modified graphene/polybutene composite masterbatch material and its preparation method and application

A technology of graphene and polybutene, which is applied in the field of modified graphene/polybutene composite masterbatch materials and its preparation, can solve the problem of affecting heating efficiency and comprehensive utilization of heat energy, limiting the performance of thermally conductive materials, and general mechanical properties and other problems, to achieve the effect of solving the low comprehensive utilization rate of heat energy, solving the low heating efficiency, and easy to disperse evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

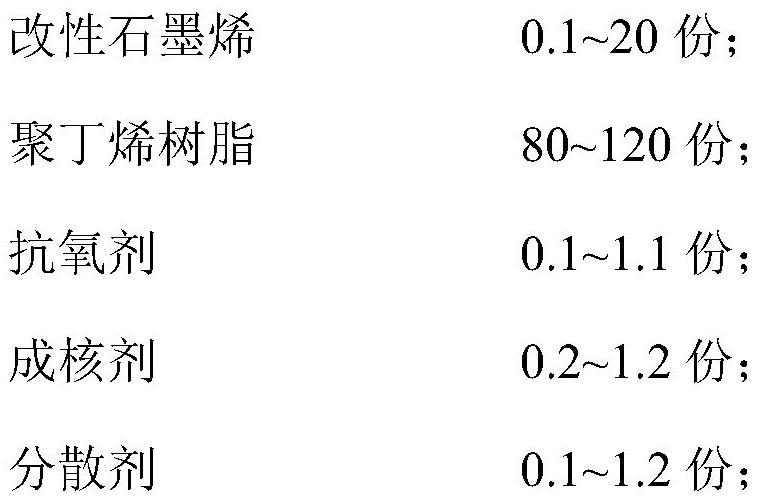

[0033] This embodiment provides 6 different modified graphene / polybutene composite masterbatch materials 1-6, which are prepared from the following raw materials in parts by weight.

[0034] Table 1

[0035]

[0036] Wherein, the composition and preparation method of the master batch material 4 and the master batch material 1 are basically the same, the only difference is that the raw material of the material 4 does not contain a nucleating agent.

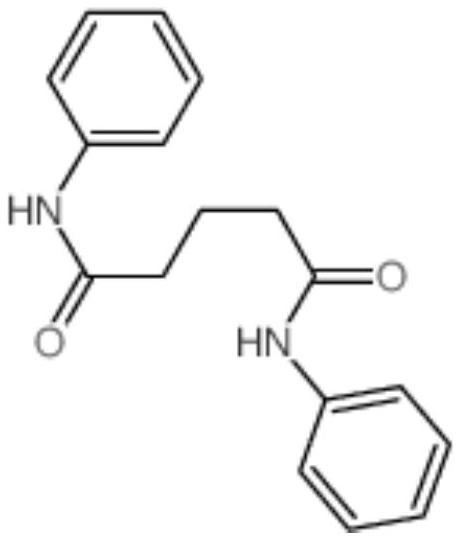

[0037] The nucleating agent is dibenzylidene sorbitol, bis(p-methylbenzylidene) sorbitol, 2,2,- dimethylene bis(4,6-tert-butylphenol) phosphonate and its derivatives One of them, mixed with one of the diamide compounds, the preferred ratio of the two is (2-5:1), the structural formula of N,N'-bis(phenyl)glutaramide in the above embodiment is:

[0038]

[0039] In other embodiments, the diamide compound can also be selected from the general formula: R 1 -NH-C(O)-R-C(O)-NH-R 1 diamides.

[0040] The preparation method of de...

Embodiment 2-4、 comparative example 1-3

[0053] This embodiment provides the application of 6 kinds of modified graphene / polybutene composite masterbatch materials described in embodiment 1 in polybutene pipes.

[0054] After getting the modified graphene / polybutene composite masterbatch material described in Example 2-4 and Comparative Example 1-3 and pipe grade polybutene resin to stir evenly, join in the plastic pipe extruder and make polybutene vinyl composite pipe. The concrete components of embodiment 2-4 and comparative example 1-3 are as shown in table 3:

[0055] Table 3 Polybutylene Composite Pipe Components

[0056] Modified graphene / polybutene composite masterbatch material Pipe Grade Polybutene Resin Example 2 Masterbatch material 1-----5 parts by weight 100 parts by weight Example 3 Masterbatch material 2-----1 parts by weight 100 parts by weight Example 4 Masterbatch material 3-----100 parts by weight 100 parts by weight Comparative example 1 Masterbatch ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com