Oxycobalt hydroxide particulate powder and manufacturing method therefor

A cobalt oxide, hydrogen oxide technology, applied in cobalt oxide/cobalt hydroxide, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as unstable crystal structure, achieve small BET specific surface area value, inhibit battery expansion, thermal Stability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0175]

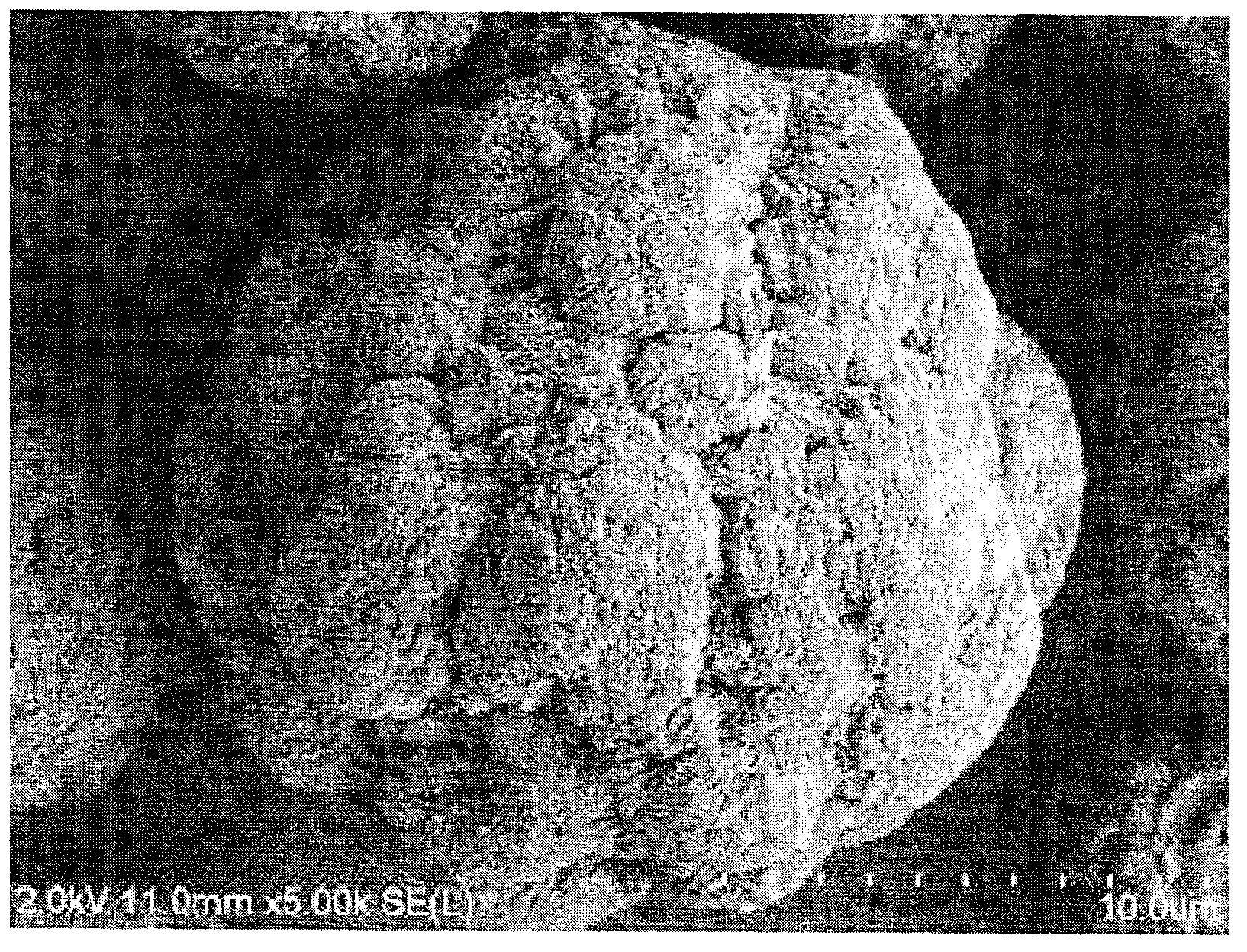

[0176] In a reactor with an effective volume of 10L equipped with flow tubes, baffles, and blade-type agitators, add 8L of ion-exchanged water, adjust the temperature to 50°C while fully stirring, and feed enough oxygen-containing gas from the lower part of the reactor. A 4 mol / l sodium hydroxide aqueous solution was added dropwise to make pH = 12.5. A 1.5 mol / l cobalt sulfate aqueous solution was continuously supplied to the reactor at an average supply rate of 0.025 mol / (l·hr). Simultaneously, a 4 mol / l sodium hydroxide aqueous solution was continuously supplied so that pH=12.5. The rapidly oxidized cobalt oxyhydroxide particles overflow from the upper part of the reactor, concentrate in a 0.4L concentrator connected to the overflow pipe, circulate to the reactor, and react until the concentration of cobalt oxyhydroxide particles in the reactor is Up to 15mol / l.

[0177] After the reaction, the taken-out suspension was washed with water using a filter press, and...

reference example 1-2

[0192]

[0193] The cobalt oxyhydroxide particle powder obtained in Comparative Example 1-4 and the lithium compound were mixed sufficiently in a predetermined amount so that the molar ratio of lithium / cobalt was 1.00, and the mixed powder was fired at 1000° C. for 10 hours in an oxidizing atmosphere, Lithium cobaltate particle powder was obtained.

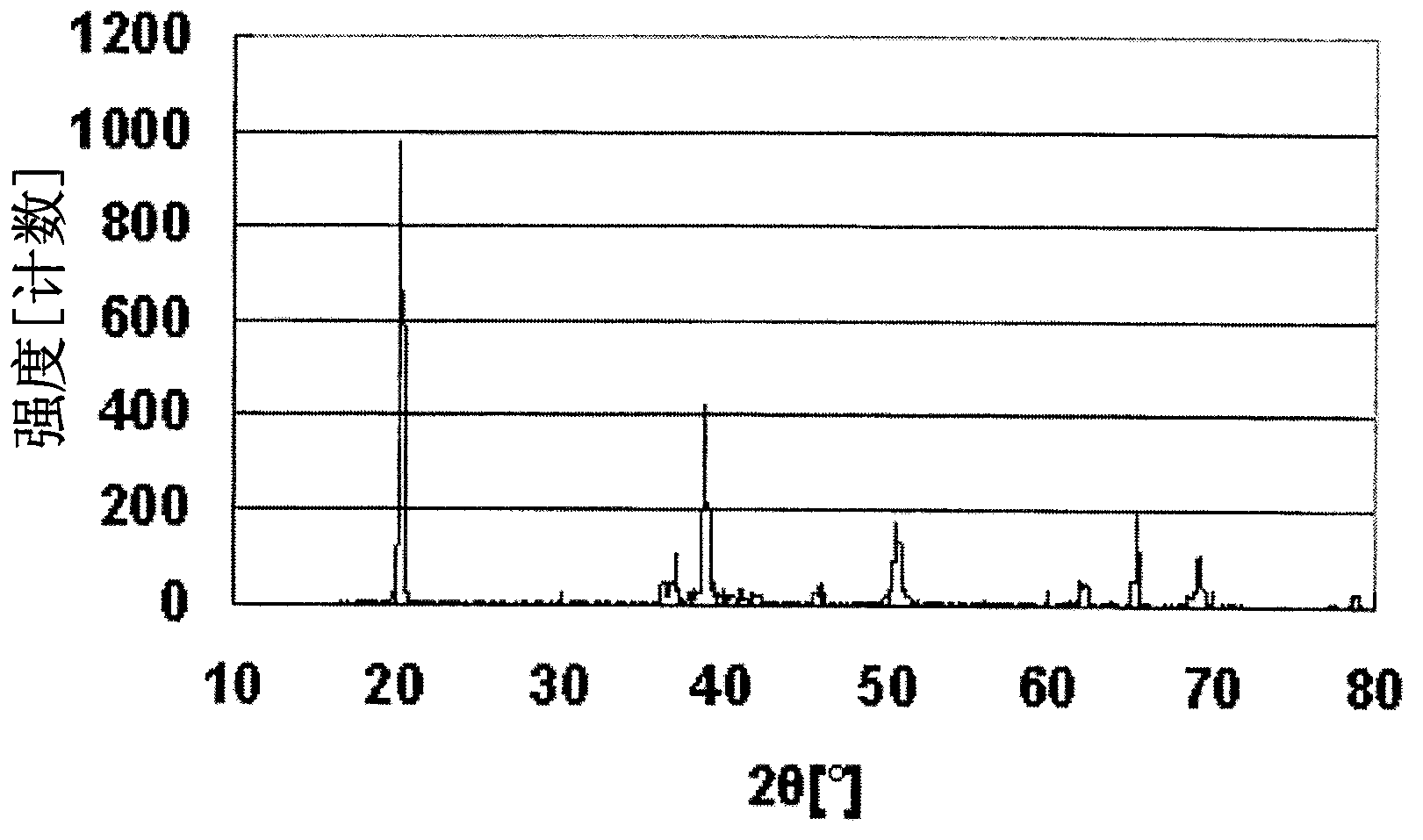

[0194] As a result of X-ray diffraction of the obtained lithium cobaltate particle powder, it is a single phase of lithium cobaltate, and no impurity phase exists. In addition, the average particle size is 13.6μm, the frequency is 9.4%, and the BET specific surface area value is 0.26m 2 / g, compressed density CD (2.5ton / cm 2 ) is 3.65g / cm 3 .

[0195] A button-type battery made of the above-mentioned positive electrode active material with a density of 3.40 g / cm 3 , The initial efficiency is 94%, the ratio characteristic (1c / 0.1c) is 92%, and the capacity retention rate of 11 cycles is 90%.

[0196] Next, Examples 2-1 to 2-...

Embodiment 2-1

[0240]

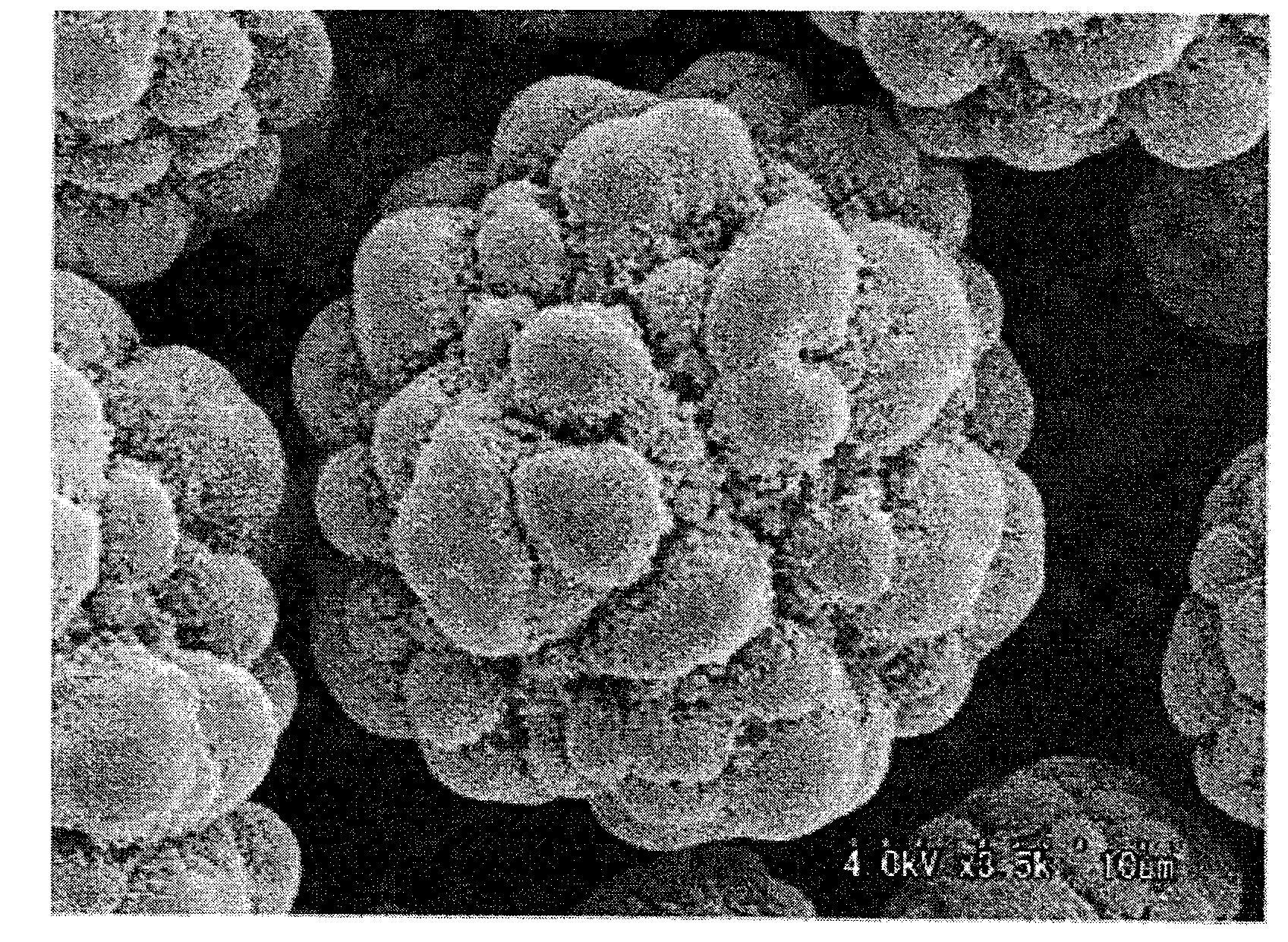

[0241] In a reactor with an effective volume of 10L equipped with flow tubes, baffles, and blade-type agitators, add 8L of ion-exchanged water, adjust the temperature to 50°C while fully stirring, and feed enough oxygen-containing gas from the lower part of the reactor. A 4 mol / l sodium hydroxide aqueous solution was added dropwise to make pH = 12.5. A 1.5 mol / l cobalt sulfate aqueous solution was continuously supplied to the reactor at an average supply rate of 0.025 mol / (l·hr). Simultaneously, a 4 mol / l sodium hydroxide aqueous solution was continuously supplied so that pH=12.5. The rapidly oxidized cobalt oxyhydroxide particles overflow from the upper part of the reactor, concentrate in a 0.4L concentrator connected to the overflow pipe, circulate to the reactor, and react until the concentration of cobalt oxyhydroxide particles in the reactor is Up to 15mol / l.

[0242] After the reaction, the taken-out suspension was washed with water using a filter press, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com