Noncircular stator inner loop curve single-action vane pump

An in-stator, vane pump technology, applied in the field of hydraulic pumps, can solve problems such as limiting the lower limit of the use speed of the vane pump.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

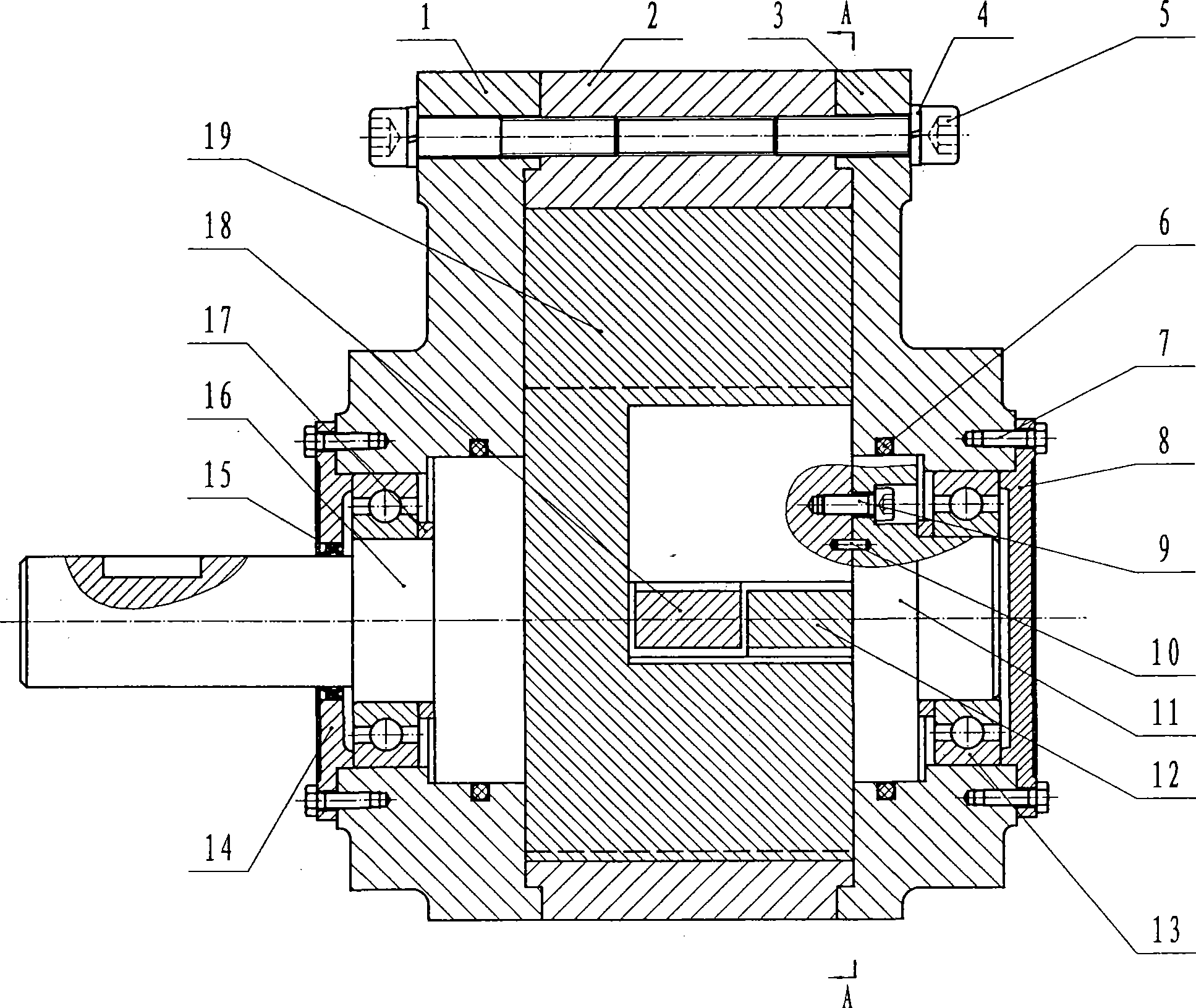

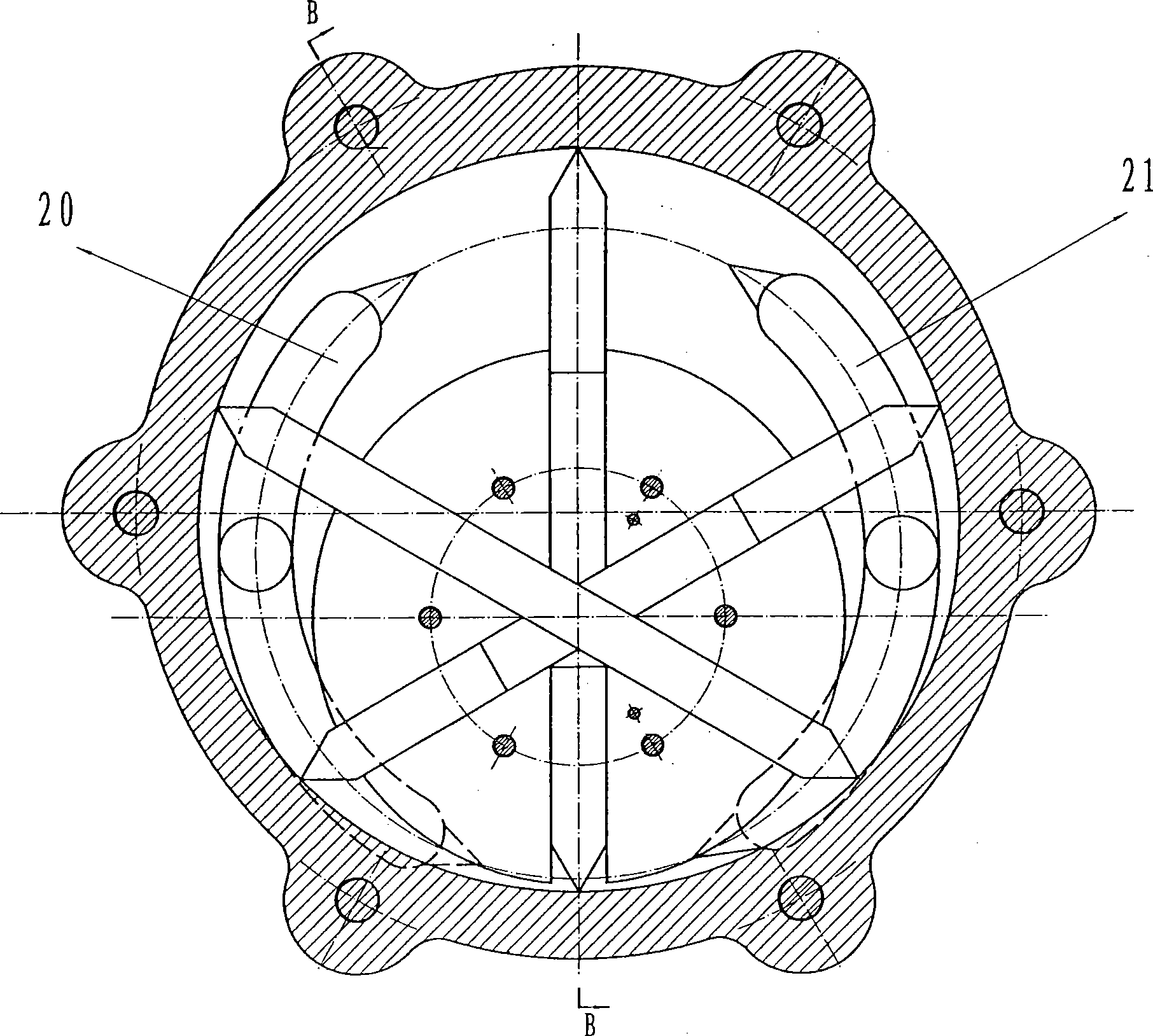

[0020] A non-circular stator inner ring curve single-acting vane pump, mainly composed of a left gland 1, a stator 2, a right gland 3, a gasket 4, a connecting screw 5, a sealing ring 6, a locking screw 7, a right end cover 8, and a screw 9 , positioning pin 10, shaft 11, right vane 12, bearing 13, left end cover 14, dustproof ring 15, rotor shaft 16, retaining ring 17, middle vane 18, left vane 19, the axis of rotor shaft 16 is in the vane pump It is projected into a point in the cross section and coincides with the pole of the non-circular closed curve. The rotor shaft 16 is provided with a radially penetrating blade slot. The length and width of the blade slot are equal to the blade width and thickness. The right blade 12, the middle blade 18, the left blade 19 radially passes through the vane groove of the rotor shaft 16 and can slide freely in the radial direction.

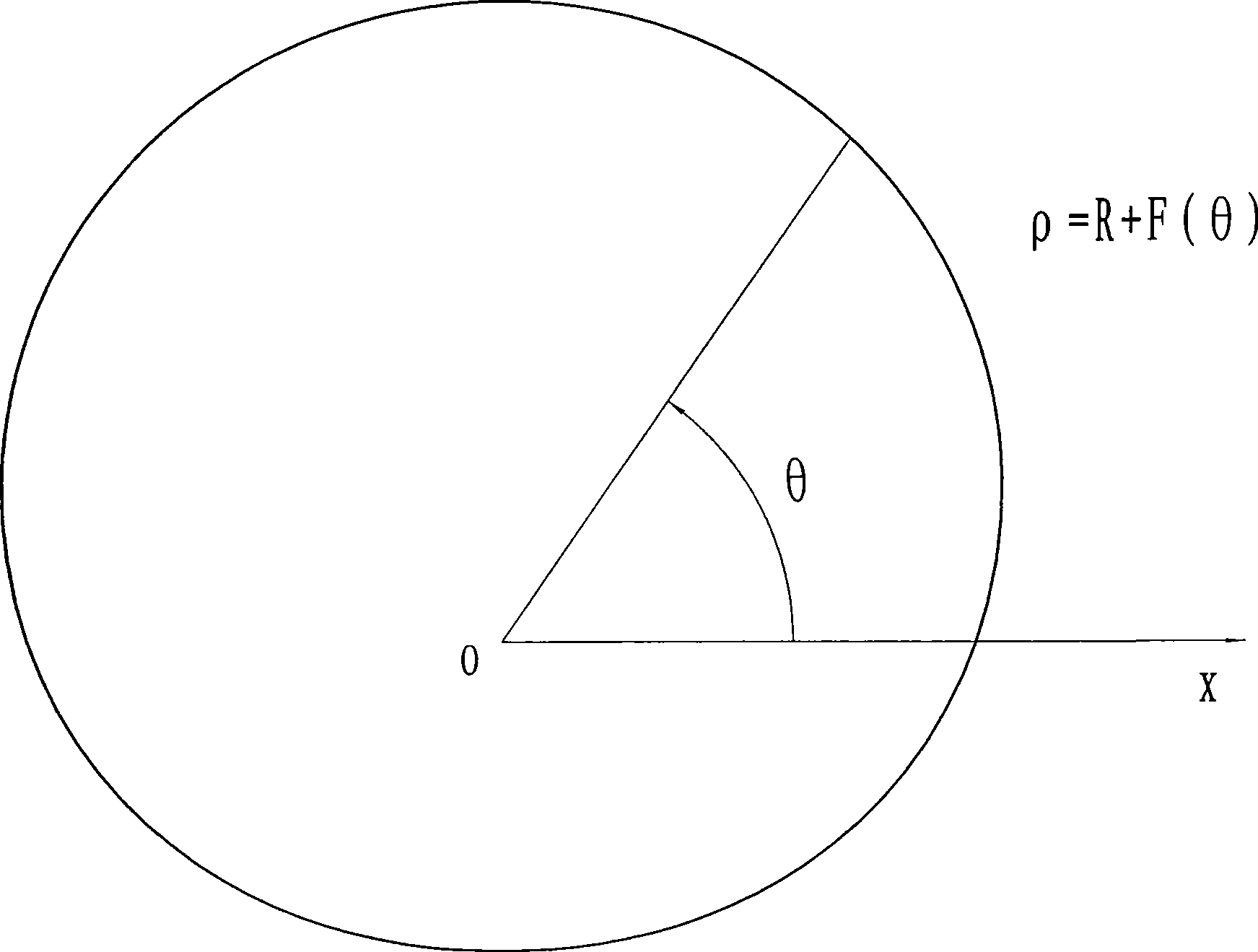

[0021] The polar coordinate equation of the stator inner ring curve is defined as ρ=R+S sinθ, where R=100m...

Embodiment approach 2

[0024] The polar coordinate equation of the stator inner ring curve is defined as ρ=R+F(θ),

[0025] where R=100mm, F ( θ ) = 16 · θ θ ∈ [ 0 , π 2 ] - 16 · θ + 16 π θ ∈ [ π ...

Embodiment approach 3

[0028] The polar coordinate equation of the stator inner ring curve is defined as ρ=R+F(θ),

[0029] where R=100mm, F ( θ ) = - 10 θ 2 + 10 πθ θ ∈ [ 0 , π ] 10 θ 2 + 20 π 2 - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com