Radiator fan

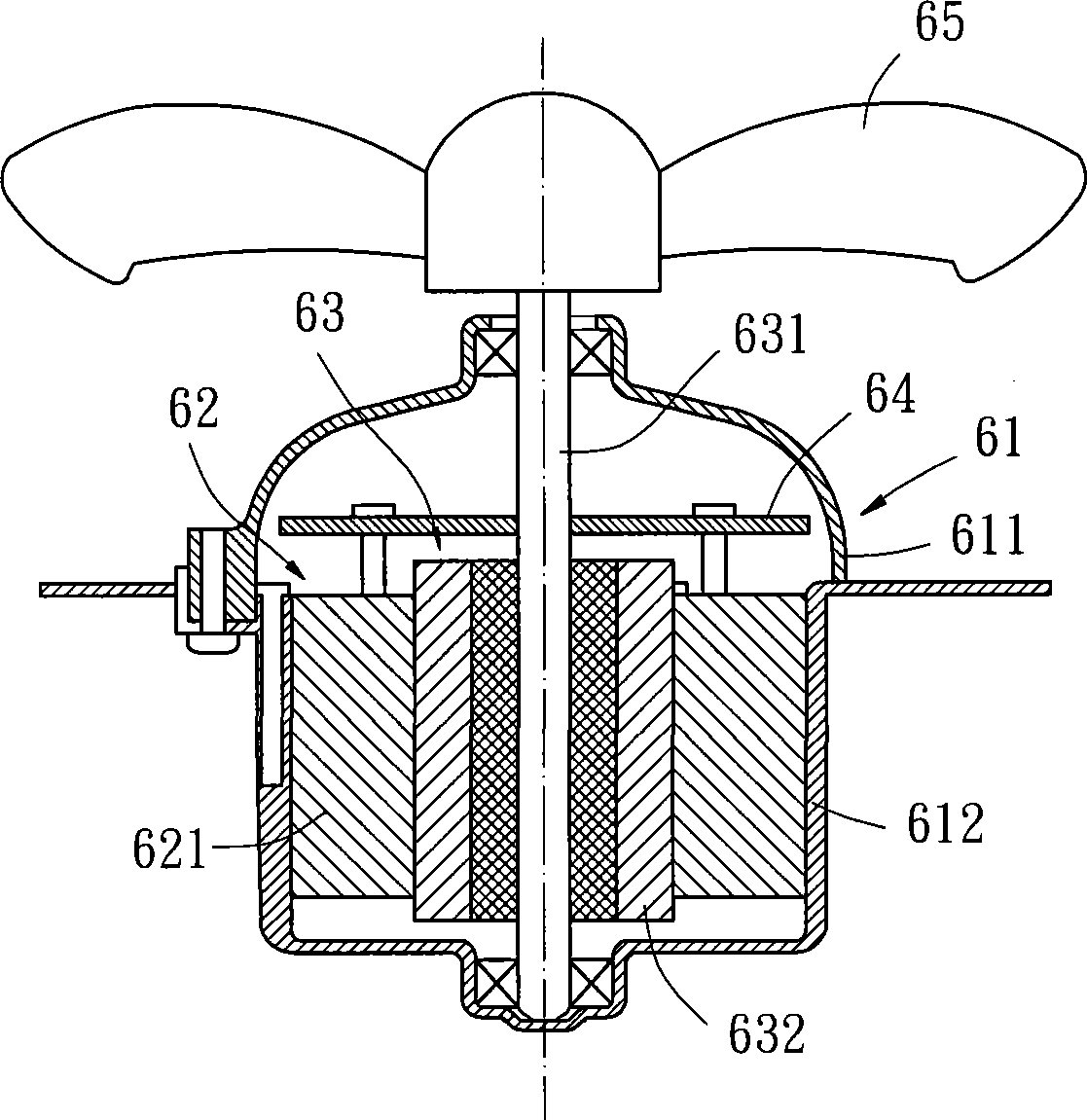

A technology for cooling fans and fan frames, which is applied to electromechanical devices, electrical components, liquid fuel engines, etc., can solve problems such as damage to electronic components, inconvenient use and installation, and difficulty in dissipating heat from the drive device 64.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the above and other objects, features and advantages of the present invention more clearly understood, preferred embodiments of the present invention will be exemplified below and described in detail in conjunction with the accompanying drawings.

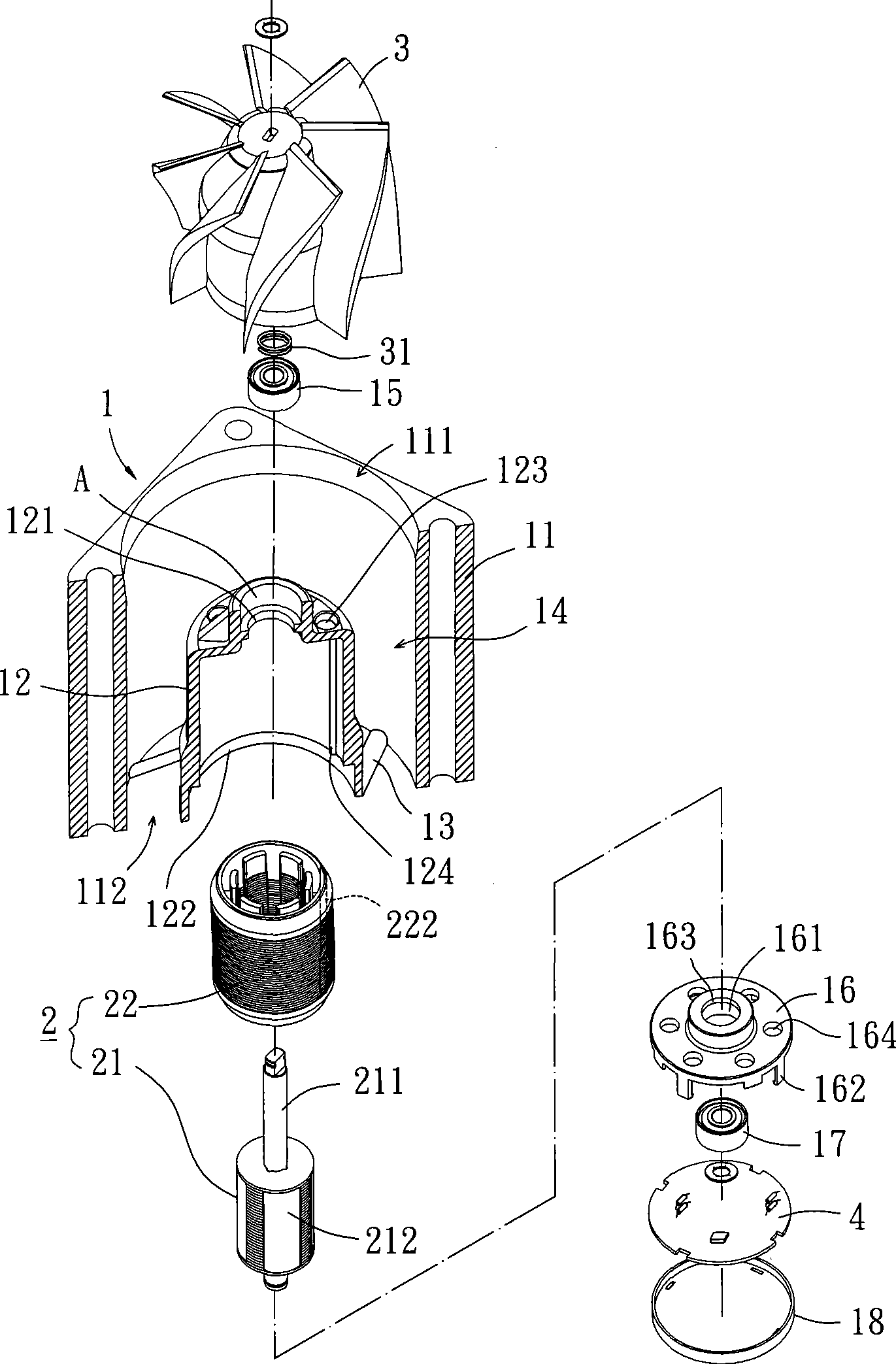

[0040] Such as image 3 As shown, the cooling fan according to the first embodiment of the present invention mainly includes a fan frame 1 , an inner rotor motor 2 , an impeller 3 and a circuit board 4 . The fan frame 1 is an integrally formed frame; the inner rotor motor 2 is arranged inside the fan frame 1; the impeller 3 is combined with the inner rotor motor 2; the circuit board 4 is electrically connected to the inner rotor motor 2 for control The inner rotor motor 2 drives the impeller 3 to rotate.

[0041] The fan frame 1 of the first embodiment of the present invention has an outer frame portion 11, an air inlet 111 and an air outlet 112 are respectively formed at two ends of the outer frame portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com