Safety check system of manifold effect detection fusing technology applying X ray

A safety inspection and X-ray technology, applied in the field of safety inspection radiation imaging, can solve the problems of inability to obtain the density information of the composition of the inspected object, inability to detect flake dangerous goods, etc., achieving convenient operation, low inspection dose, and improved detection rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

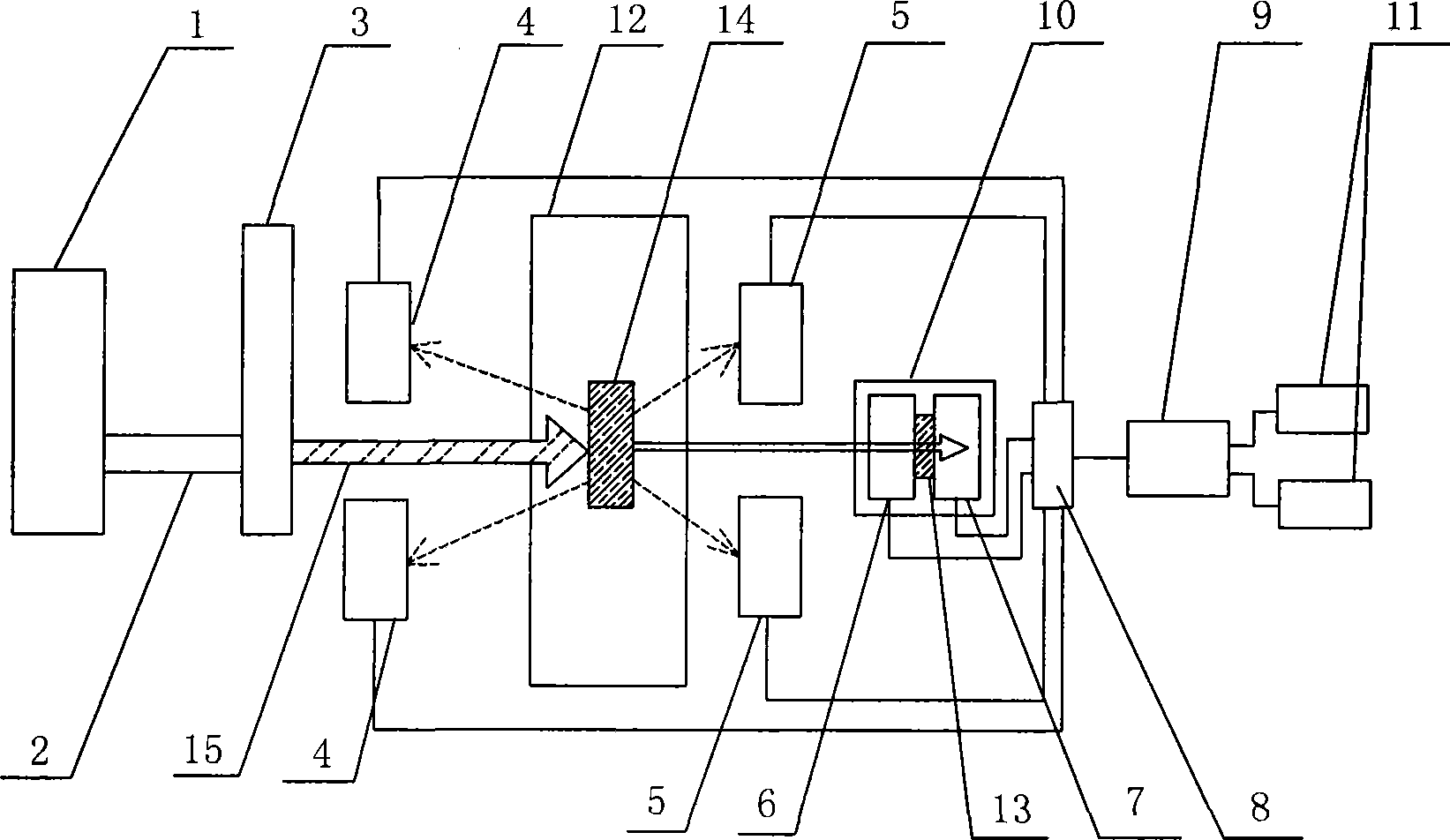

[0030] Such as figure 1 As shown, a safety inspection system using X-ray multi-effect detection fusion technology includes an X-ray source 1, a collimator 2, a chopper device 3, a dual-energy transmission detector 10, two forward scatter detectors 5, two A backscatter detector 4, a signal processor 8, a computer system 9, two color displays 11 and a delivery system 12, an X-ray source 1 emits a conical X-ray beam, and a collimator 2 collimates the conical X-ray beam into The slice fan-shaped X-ray beam, the chopper device 3 modulates the slice fan-shaped X-ray beam into a pen beam-shaped X-ray flying spot 15 moving from bottom to top or from top to bottom, and the angle of the knife-edge plate of the chopping device 3 varies with the X-ray beam The angle changes; the pencil beam X-ray flying spot 15 interacts with the object 14 on the conveying system 12, and the X-ray scattered by the object 14 is detected by two backscatter detectors 4 and two front scatter detectors. 5 rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com