Method and apparatus for on-line measuring two-dimension speed and particle size distribution of granules in pipe

A particle size distribution and internal particle technology, applied in the direction of measuring devices, particle and sedimentation analysis, particle size analysis, etc., can solve the problems of complex system, difficult on-site layout, expensive equipment, etc., and achieve compact measurement system, strong on-site operability, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Referring to the accompanying drawings, the implementation method of the present invention will be described in detail below.

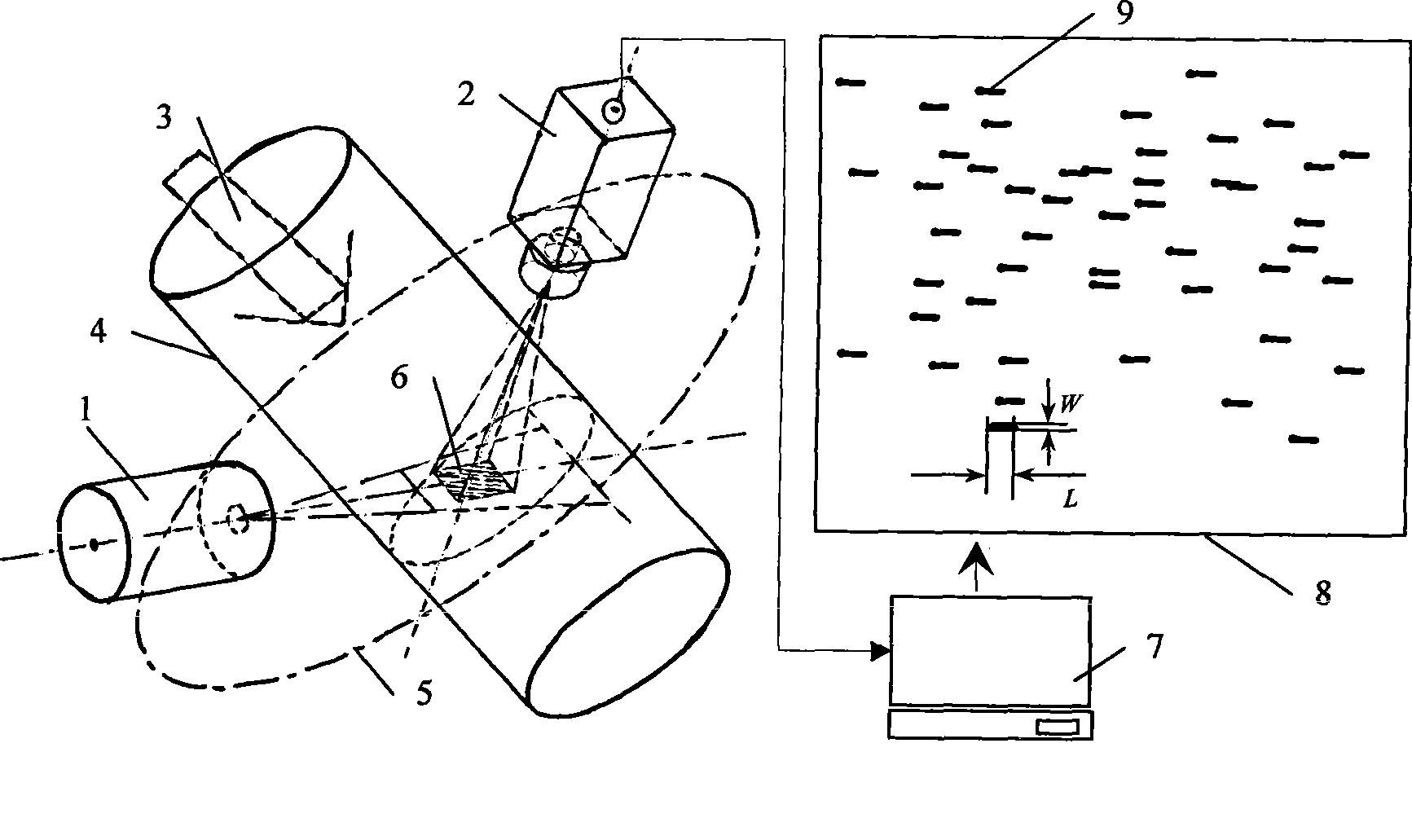

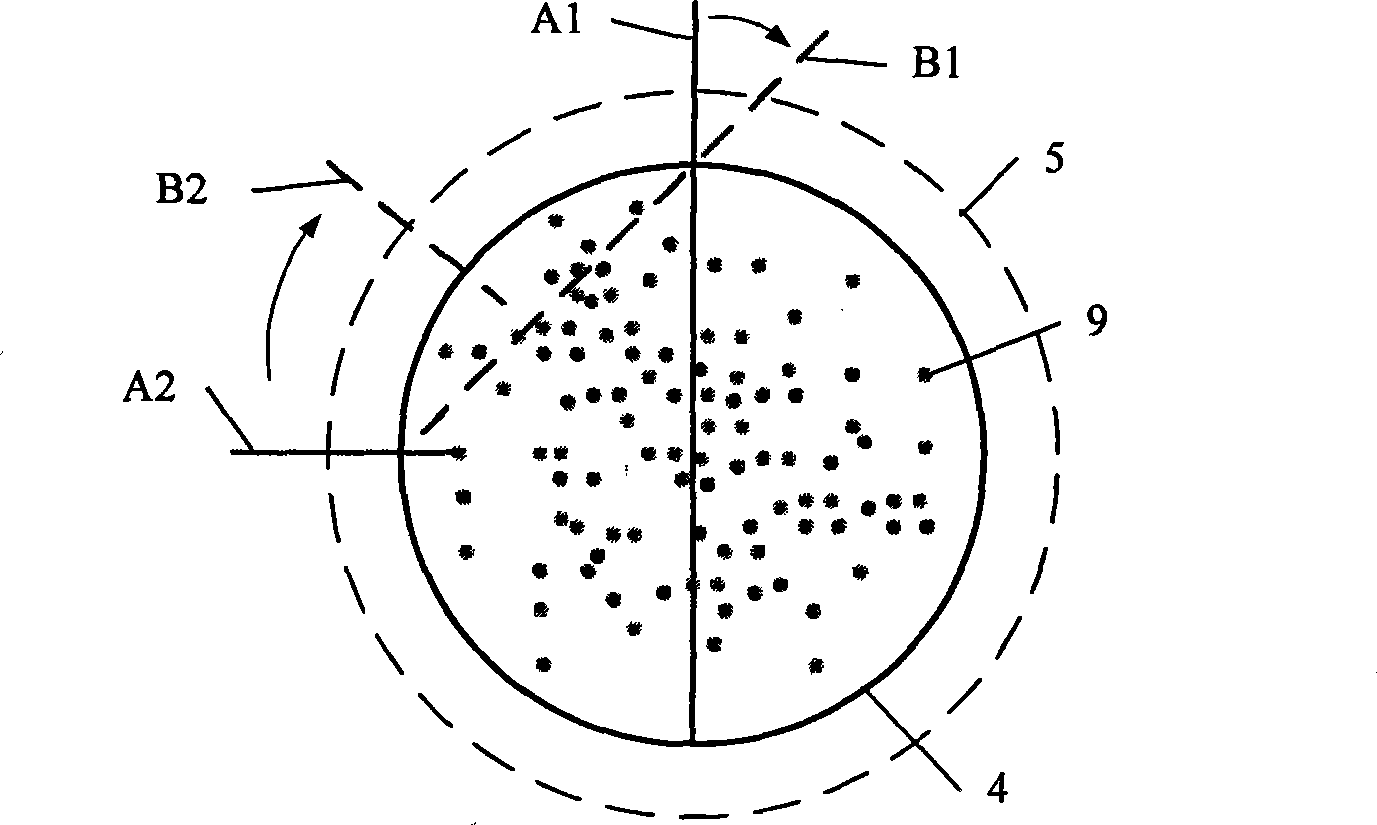

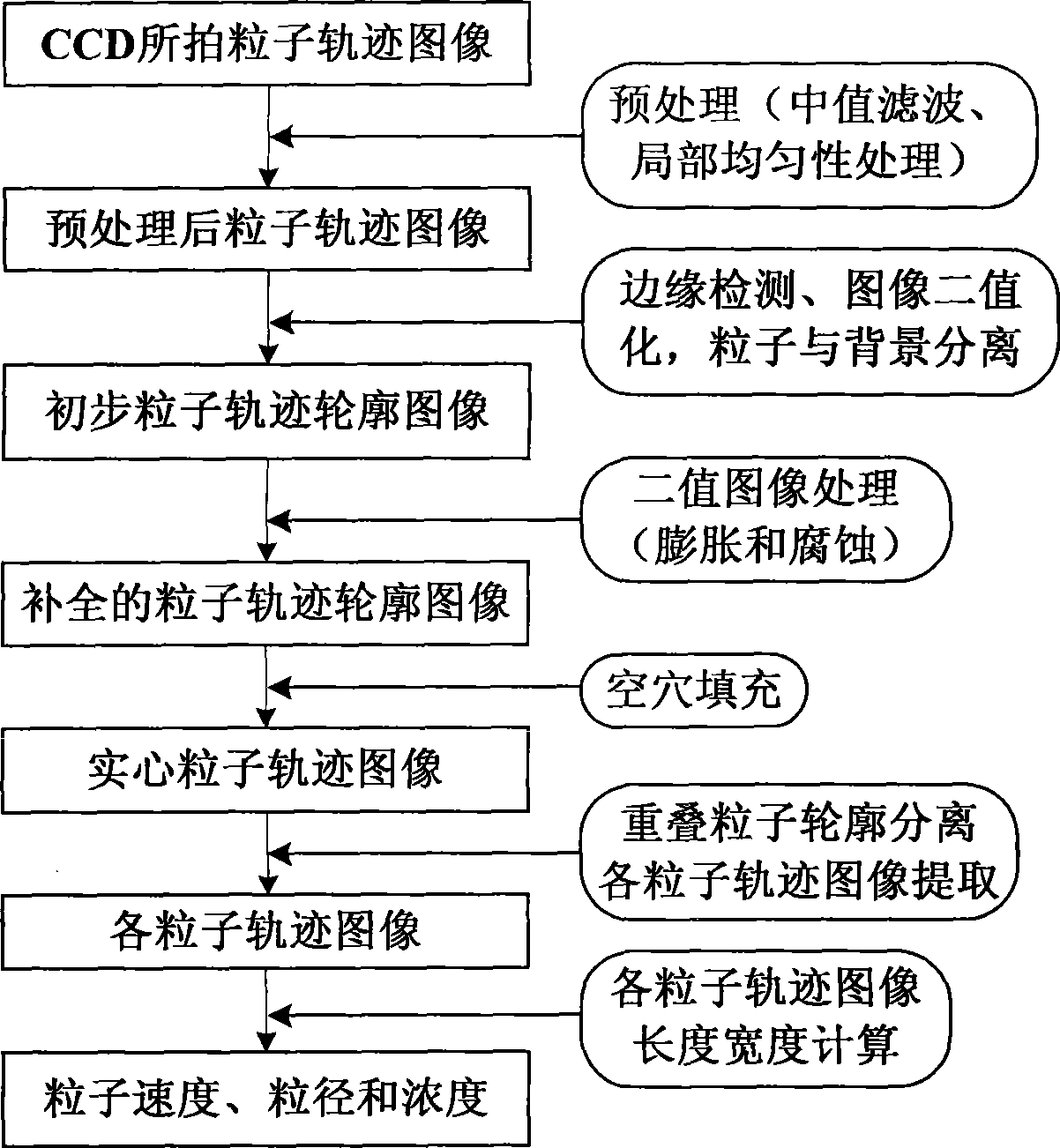

[0031] In the present invention, the device for realizing on-line real-time measurement of the two-dimensional velocity field and particle size distribution of gas-solid two-phase flow particles in the pipe includes a low-power continuous laser 1 emitting a light source; the laser 1 is movably installed in a surrounding industrial pneumatic conveying On the guide rail 5 of the pipeline 4, the plane of the guide rail 5 is perpendicular to the axis of the industrial pneumatic conveying pipeline 4; a CCD camera 2 equipped with a zoom lens is also movably installed on the guide rail 5, and the direction of the lens is perpendicular to the direction of the plane of the light source ; The measured position of the industrial pneumatic conveying pipeline 4 is equipped with a transparent glass window. Both the laser 1 and the CCD camera 2 can slide on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com